Polyurethane adhesive and plastic track prime material as well as preparation methods thereof

A technology of polyurethane adhesive and polyurethane prepolymer, applied in the direction of polyurea/polyurethane coatings, polyurea/polyurethane adhesives, adhesives, etc., can solve the problems of affecting human health and high free isocyanate content, and achieve adhesion Strong, low free isocyanic acid content, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

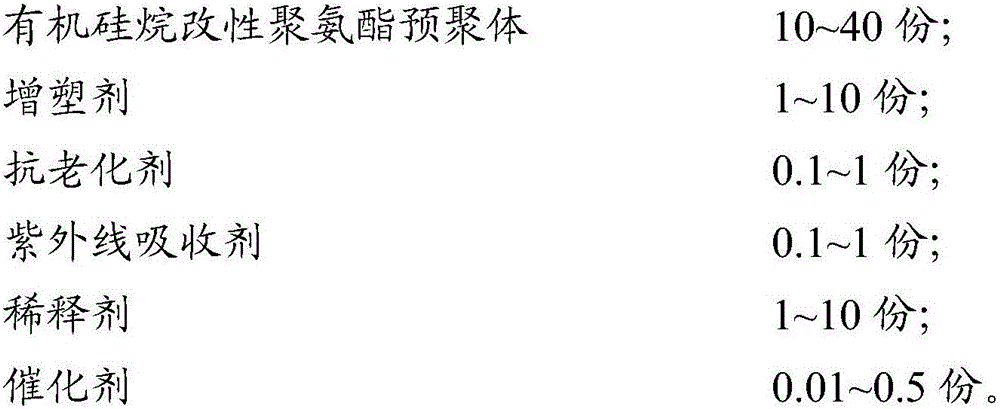

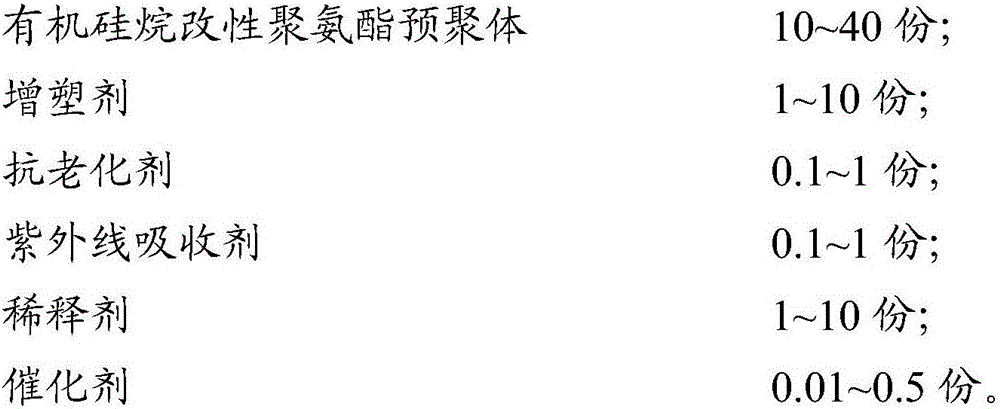

[0033] Weigh 100 parts of polypropylene carbonate diol, add it into a glass reaction kettle with a vacuum device, vacuumize and dehydrate at 100°C for 2 hours, add 0.04 parts of phosphoric acid, 0.04 parts of stannous octoate, and carbodiimide modified bismuth 70 parts of phenylmethane diisocyanate (liquefied MDI), reacted at 80°C for 2 hours, cooled to 10°C, added 5 parts of KH540, and reacted for 1 hour to obtain an organosilane-modified polyurethane prepolymer.

[0034] Take 40 parts of the above prepolymer, 10 parts of plasticizer, 1 part of anti-aging agent, 1 part of ultraviolet absorber, 1 part of diluent, and 0.01 part of catalyst, and stir them evenly in a reaction kettle at room temperature to obtain polyurethane adhesive .

[0035] The polyurethane adhesive and black rubber particles are mixed in a hand mixer in a weight ratio of 1:8, then paved, and then compacted in a mold to obtain the bottom material of the plastic runway.

Embodiment 2

[0037] Weigh 100 parts of polypropylene carbonate diol, add it into a glass reactor with a vacuum device, vacuum dehydrate at 100°C for 2 hours, add 0.04 parts of phosphoric acid, 0.04 parts of stannous octoate, 70 parts of liquefied MDI, and heat at 80°C React for 2 hours, lower the temperature to 40° C., add 10 parts of KH550, and react for 1 hour to obtain an organosilane-modified polyurethane prepolymer.

[0038] Take 40 parts of the above-mentioned prepolymer, 8 parts of plasticizer, 0.5 part of antiaging agent, 0.5 part of ultraviolet absorber, 2 parts of diluent, and 0.01 part of catalyst, and stir them evenly in a reaction kettle at room temperature to obtain polyurethane adhesive .

[0039] The polyurethane adhesive and black rubber particles are mixed in a hand mixer at a weight ratio of 1:8, then paved, and then compacted in a mold to obtain the bottom material of the plastic runway.

Embodiment 3

[0041] Weigh 100 parts of polypropylene carbonate diol, add it into a glass reactor with a vacuum device, vacuum dehydrate at 100°C for 2 hours, add 0.01 part of phosphoric acid, 0.1 part of stannous octoate, 70 parts of liquefied MDI, and heat at 60°C React for 5 hours, lower the temperature to 40° C., add 15 parts of KH550, and react for 1 hour to obtain an organosilane-modified polyurethane prepolymer.

[0042] Take 30 parts of the above prepolymer, 5 parts of plasticizer, 0.5 part of anti-aging agent, 0.5 part of ultraviolet absorber, 3 parts of diluent, and 0.01 part of catalyst, and stir them evenly in a reaction kettle at room temperature to obtain polyurethane adhesive .

[0043] The polyurethane adhesive and black rubber particles are mixed in a hand mixer at a weight ratio of 1:8, then paved, and then compacted in a mold to obtain the bottom material of the plastic runway.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com