Process for welding electronic microcomponents based on multi-temperature gradient

A process method and micro-component technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of less welding temperature steps, difficult quantitative flaw detection, and low multi-functional integration, so as to achieve less welding voids and avoid Detection problems, stable and reliable processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

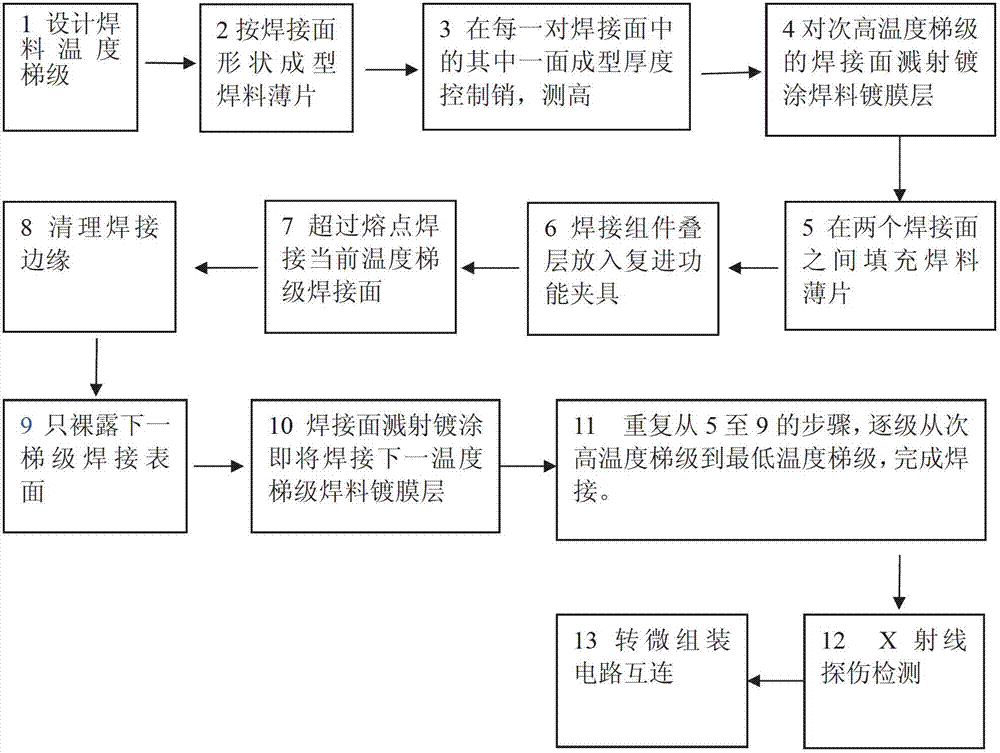

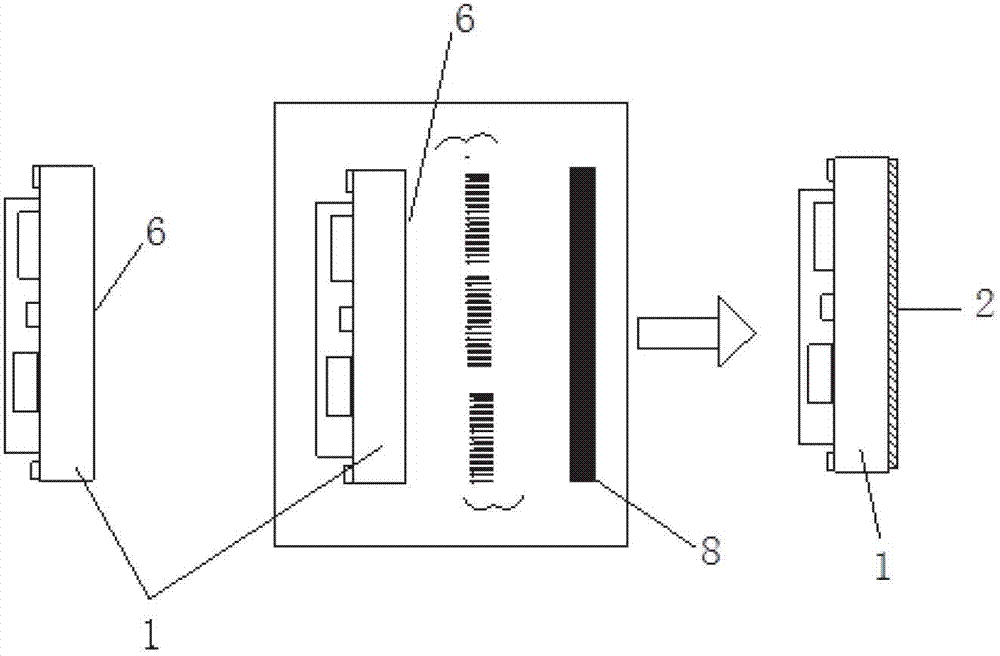

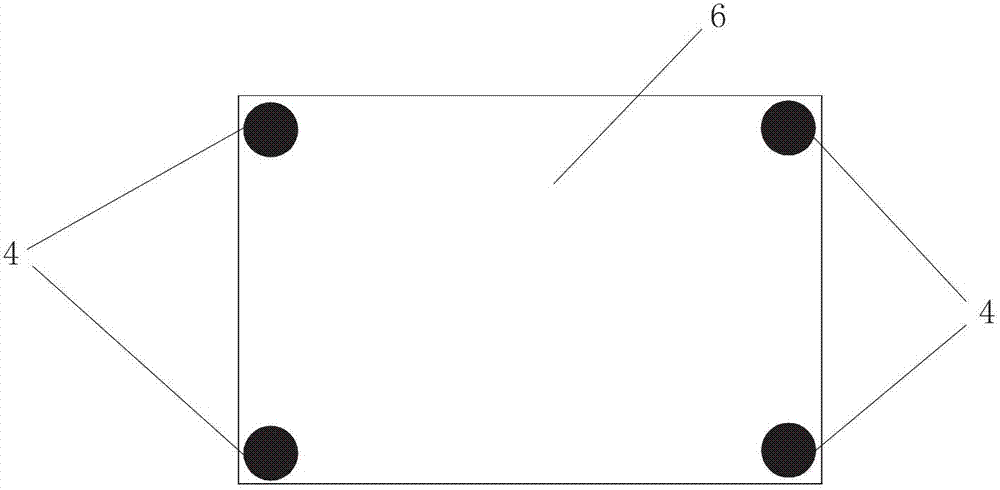

[0030] refer to figure 1 . The target material 8 is the source of the physical coating material. Different target materials have different melting point temperatures and components. The melting point and composition of the formed welding surface coating layer 2 are exactly the same as the melting point and composition of the solder sheet 3 material corresponding to the melting point temperature. The coating layer on the soldering surface of the electronic micro-component 1 and the solder thin sheet 3 are all the same component material. The highest temperature welding has no limit on the upper limit of temperature rise, so the temperature can be raised to solve the solderability problem. The base assembly 5 is a relative concept. For the microelectronic assembly 12, it is the bond connected with the TR assembly cavity 11. For the TR assembly, it refers to the final packaging shell of the entire assembly; the shape of the solder sheet 3 is completely consistent with the shape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com