Method for rolling double-zero aluminum foil through 1850mm-width rolling mill

A double-zero aluminum foil and rolling mill technology, applied in the field of aluminum foil rolling, 1850mm width rolling mill to produce double-zero aluminum foil, can solve problems such as damage to the ductility of aluminum foil, deterioration of mechanical properties, etc., to expand product specifications and varieties, The effect of stable product quality and reliable process

Active Publication Date: 2017-06-13

JIANGSU DAYA ALUMINUM

View PDF6 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

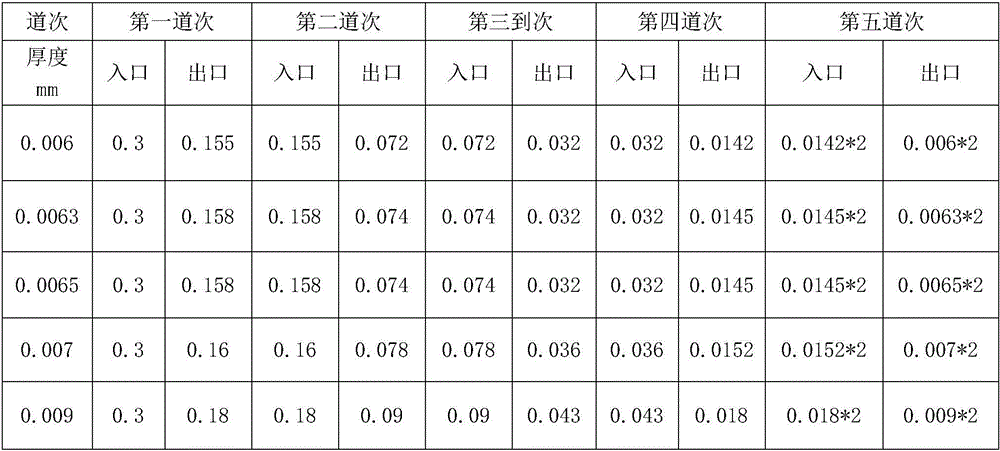

[0028] Rolling process table for producing 0.006mm aluminum foil

[0029]

Embodiment 2

[0031] Rolling process table for producing 0.0063mm aluminum foil

[0032]

Embodiment 3

[0034] Rolling process table for producing 0.0065mm aluminum foil

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Login to View More

Abstract

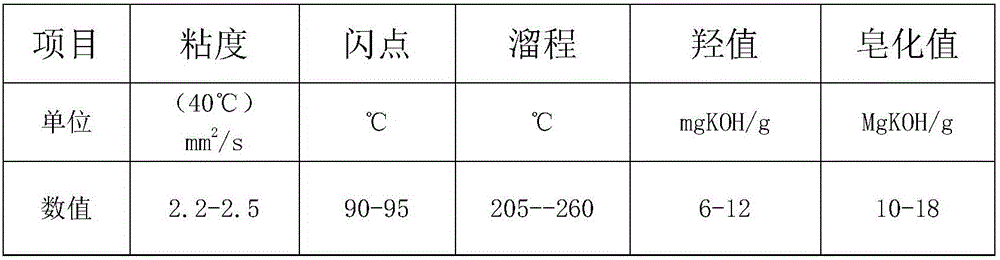

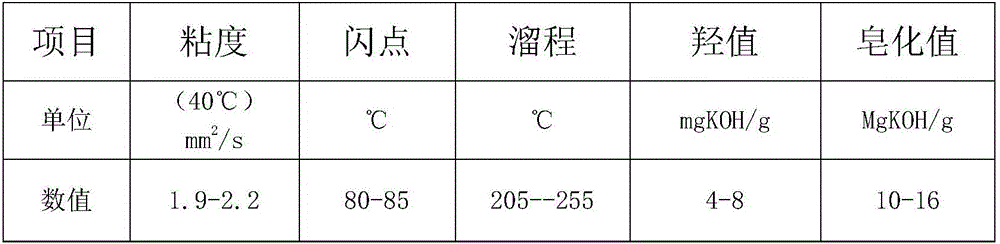

The invention discloses a method for rolling a double-zero aluminum foil through a 1850mm-width rolling mill, and belongs to the technical field of aluminum foil machining. The method comprises the following step of carrying out three-pass rough rolling, one-pass intermediate rolling and one-pass finish rolling on a cast-rolled blank or a hot-rolled blank of which the thickness is 0.3mm on the 1850mm-width rolling mill to prepare the aluminum foil of which the thickness is 0.006-0.009mm and the width is 1,000-1650mm, wherein the roll diameter of a working roll of the rolling mill is phi260mm, 90# rolling oil is selected in the rough rolling procedure and the intermediate rolling procedure; 82# rolling oil is selected in the finish rolling procedure; an alcohol additive and / or ester additive is selected as the additive; and the rolling oil has the specifications after being prepared by using the additive at 40 DEG C as follows: the viscosity is 1.9-2.5mm<2> / s, the flash point is 80-95 DEG C, the distillation range is 205-260 DEG C, the hydroxyl value is 4-12mgKOH / g and the saponification value is 10-18MgKOH / g. The produced product is stable in quality and high in yield.

Description

technical field [0001] The invention relates to an aluminum foil rolling method, in particular to a rolling method for producing double-zero aluminum foil with a 1850mm width rolling mill, and belongs to the technical field of aluminum foil processing. Background technique [0002] Aluminum foil is a thin sheet directly calendered by metal aluminum, usually refers to a thin strip with a thickness less than or equal to 0.2mm, and is often used as hot stamping materials, capacitors, packaging materials, etc. At present, countries have different regulations on the thickness of aluminum foil. China, France, Russia, etc. define the upper limit of the thickness of aluminum foil as 0.2mm; the United States, the United Kingdom, Japan, etc. define the upper limit of the thickness of aluminum foil as 0.15mm; The upper limit is defined as 0.02mm. [0003] In China, the thickness is usually less than 0.01mm, that is, the foil with two zeros after the decimal point is called double zero...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B1/40

CPCB21B1/40

Inventor 陈志明贾建新周晓群陈玉才

Owner JIANGSU DAYA ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com