Micro-emulsion cleaning agent for welding jigs

A welding fixture and microemulsion technology, applied in the field of cleaning agents, can solve the problems of cleaning agent failure, difficulty in rinsing, poor cleaning ability, etc., and achieve the effects of enhanced cleaning ability, good dissolution effect, and excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned microemulsion cleaning agent for welding jig comprises the following steps:

[0030] Step 1: Add the polymer stabilizer, 2-ethylhexanol polyoxyethylene polyoxypropylene ether, terpene and propylene glycol ether solvent into the reactor according to the above-mentioned weight percentages and then stir, and the stirring time is 10- For 15 minutes, the stirring speed is 50-65 rev / min to obtain mixed solution A;

[0031] Step 2: adding the saponification agent and water to another reactor according to the above-mentioned weight percentages, and stirring for 5-8min at a stirring speed of 60-80 rev / min to obtain mixed solution B;

[0032] Step 3: Pour the above mixed solution B into the reaction kettle containing the mixed solution A according to the above ratio and stir, stir for 30-40 minutes, and the stirring speed is 50-65 r / min, to obtain the welding jig of the present invention. Emulsion cleaner.

[0033] Microemulsion is ...

Embodiment 1

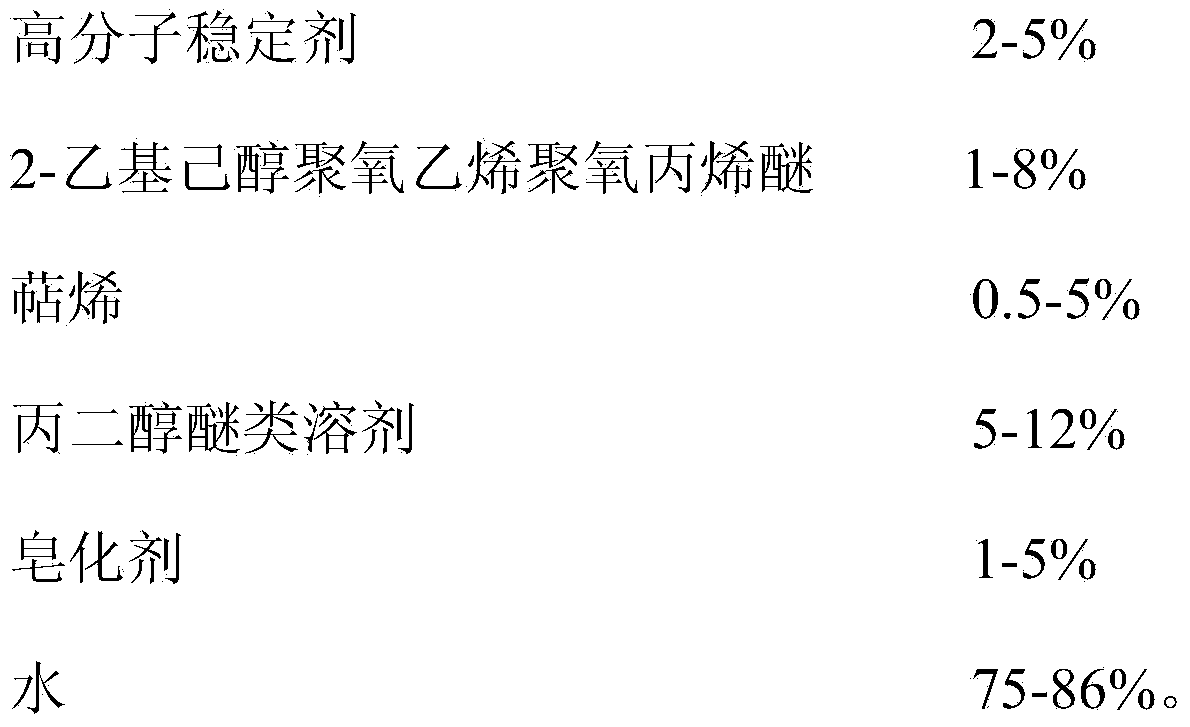

[0042] The present embodiment provides a microemulsion cleaning agent for a welding jig, which is composed of the following components by weight:

[0043]

[0044] The preparation method of the above-mentioned microemulsion cleaning agent for welding jig is as follows: polyvinylpyrrolidone, 2-ethylhexyl alcohol polyoxyethylene polyoxypropylene ether, limonene and propylene glycol ethyl ether are sequentially added to the reaction kettle according to the above weight and then stirred, The stirring time was 10 minutes, and the stirring speed was 60 rev / min to obtain mixed solution A. Ethanolamine and water are successively added in another reactor according to the above-mentioned weight, and stirred for 8min under the stirring speed of 60 revs / min to obtain mixed solution B; the gained mixed solution B is poured into the reactor equipped with mixed solution A and stirred , and stirred for 30 minutes, and the stirring speed was 60 rpm to obtain the microemulsion cleaning agent...

Embodiment 2

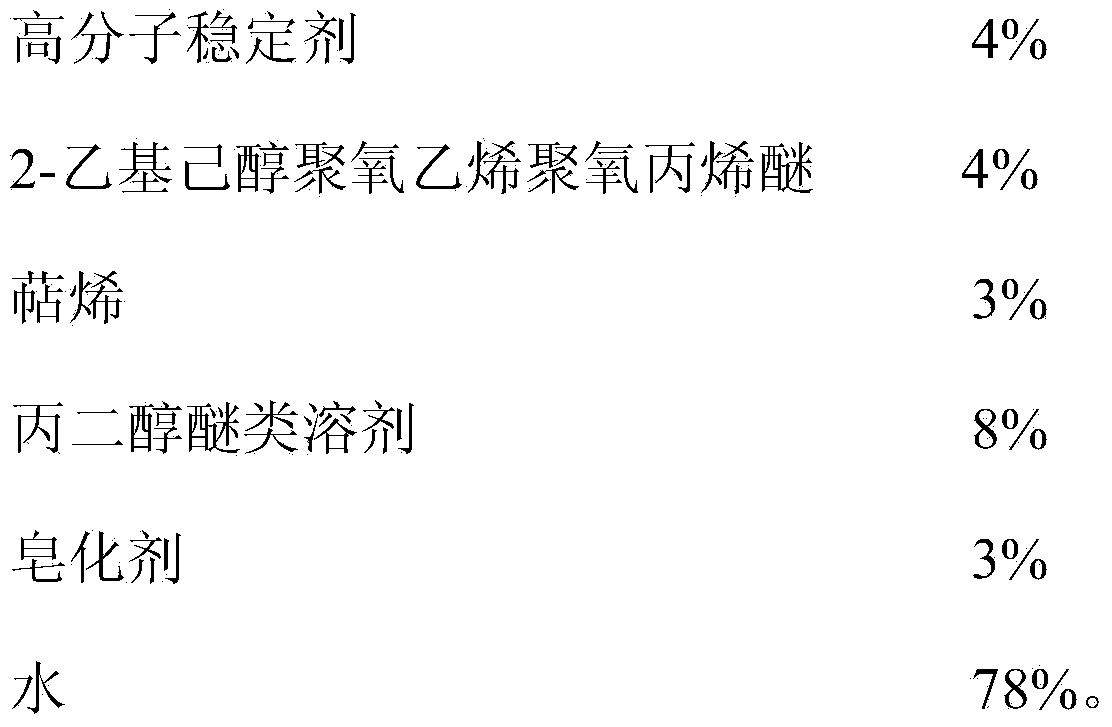

[0050] This embodiment provides a microemulsion cleaning agent for a welding jig, which is composed of the following components by weight:

[0051]

[0052] The preparation method of the above-mentioned microemulsion cleaning agent for welding jig is as follows: polyvinylpyrrolidone, 2-ethylhexanol polyoxyethylene polyoxypropylene ether, limonene and dipropylene glycol ethyl ether are sequentially added to the reaction kettle according to the above weight and then stirred. , the stirring time is 12 minutes, and the stirring speed is 50 rpm to obtain the mixed solution A. Ethanolamine and water are successively added in another reactor according to the above-mentioned weight, and stirred for 7min under the stirring speed of 70 revs / min to obtain mixed solution B; the gained mixed solution B is poured into the reactor equipped with mixed solution A and stirred , and stirred for 35 minutes, and the stirring speed was 65 rpm to obtain the microemulsion cleaning agent for the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com