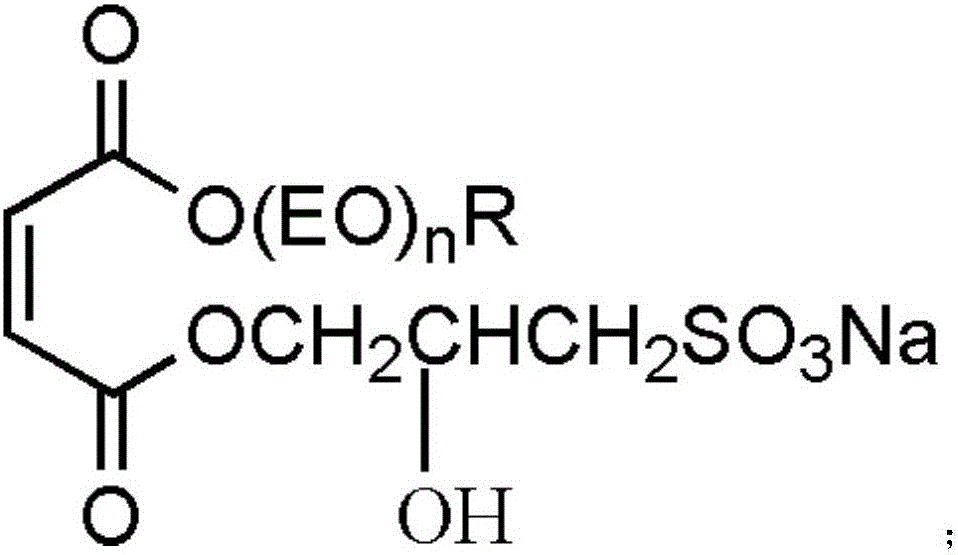

Preparation method and application of anionic nonionic reactive emulsifier

A reactive emulsifier, anion and non-ionic technology, applied in the preparation of sulfonate, organic chemistry, etc., can solve the problems of environmental biological toxicity, large emulsion particle size, deviation of hard water resistance, etc., achieve high emulsification and dispersion ability, small Effect of Particle Size and Low Surface Tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

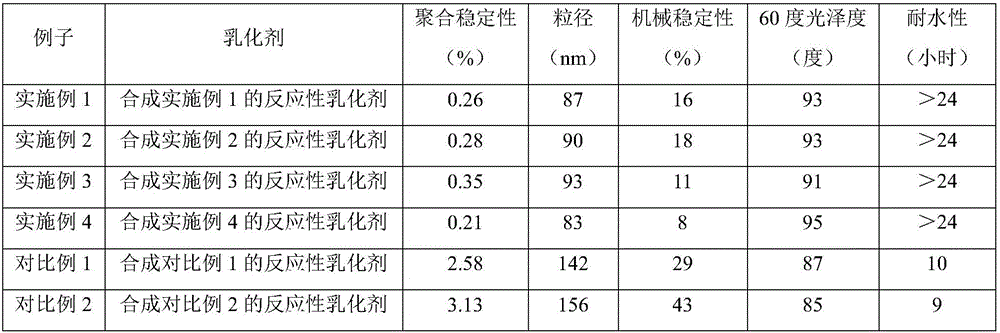

Examples

preparation example Construction

[0030] The preparation method of described a kind of negative nonionic reactive emulsifier, comprises the following steps:

[0031] 1) Maleic anhydride and secondary alcohol polyoxyethylene ether are reacted to synthesize secondary alcohol polyoxyethylene ether maleic acid monoester under the action of a catalyst;

[0032] 2) Neutralizing secondary alcohol polyoxyethylene ether maleate monoester with alkaline solution to obtain secondary alcohol polyoxyethylene ether maleate monoester salt;

[0033] 3) After reacting secondary alcohol polyoxyethylene ether maleate monoester salt with 3-chloro-2-hydroxypropanesulfonate sodium, and then adjusting the solid content of the system, an anion-nonionic reactive emulsifier was prepared.

[0034] Preferably, the mass ratio of maleic anhydride, secondary alcohol polyoxyethylene ether, catalyst, alkali, and 3-chloro-2-hydroxypropanesulfonate is (50~60):(195~970):(0.3 ~6): (18 ~ 30): (90 ~ 110); further preferably, the maleic anhydride, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com