Prepn of cationic monomer dialkyl disubstituent propyl ammonium halide

A technology of dialkyl diallyl ammonium halide and allyl ammonium halide, which is applied in the field of one-step preparation of cationic monomers, can solve problems such as incomplete reaction, intensified hydrolysis side reactions, and increased impurities, so as to avoid High temperature side reactions are intensified, the reaction material ratio is stable, and the effect of reducing the formation of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

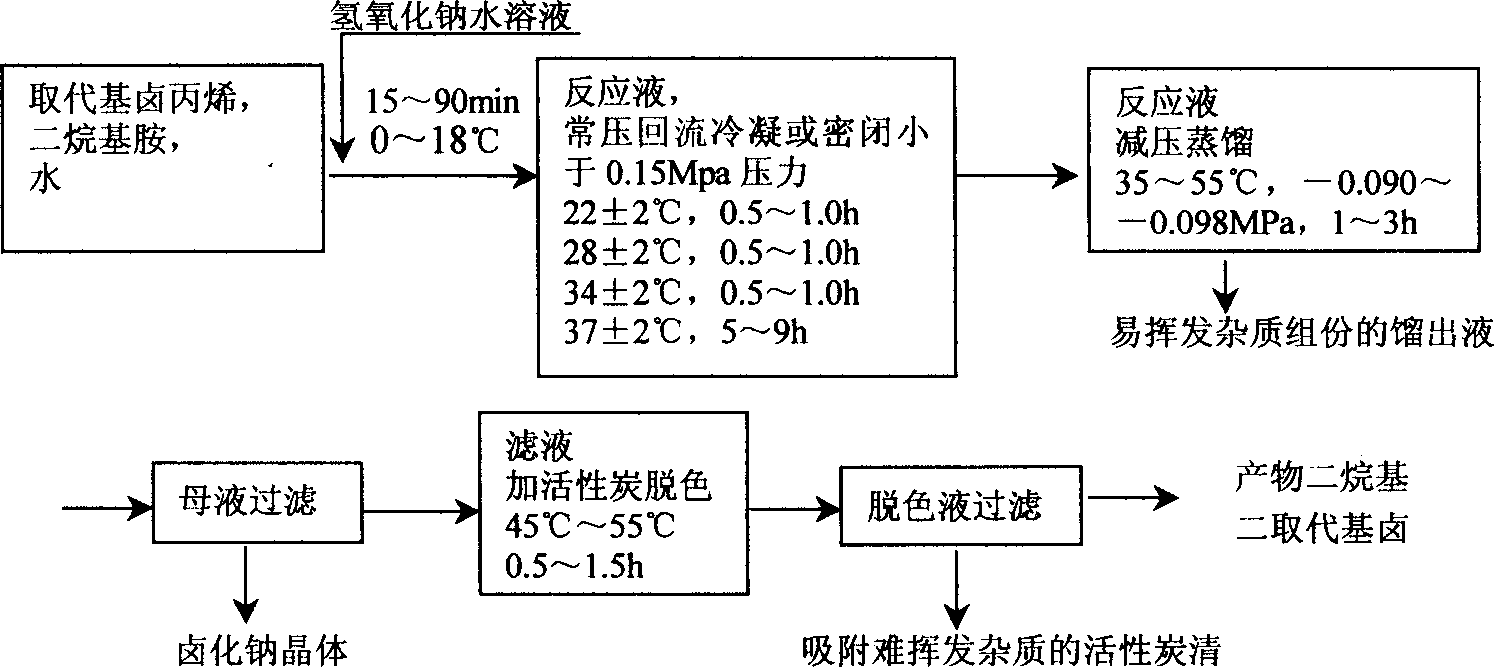

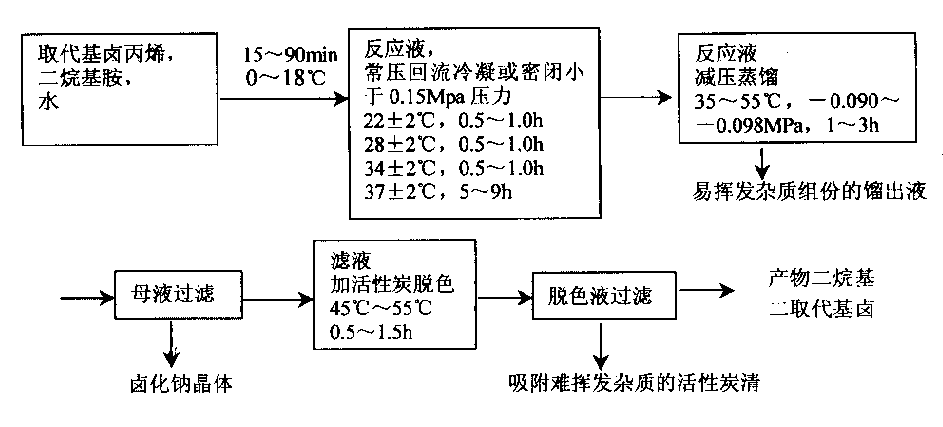

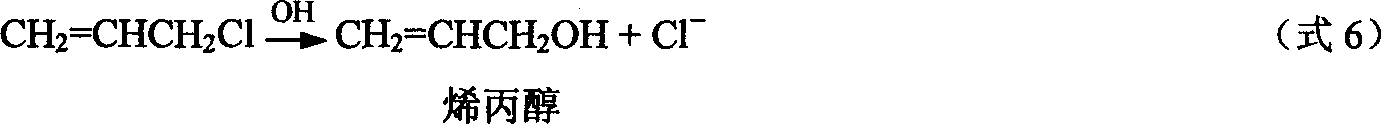

[0025] In conjunction with accompanying drawing, the embodiment of the preparation method of cationic monomer dialkyl disubstituent allyl ammonium halide of the present invention is: the first step: in the 0.12m that is equipped with reflux condensing device 3 In the enamel or stainless steel reaction kettle, pump 99% (mass fraction, the same below) industrial chloropropene 32.5±0.1kg (chloropropene 392mol), 40% dimethylamine aqueous solution 21.8±0.1kg (dimethylamine 200mol ), deionized water 2.7±0.1kg (150mol), slowly add 30% sodium hydroxide aqueous solution 24.5±0.1kg (sodium hydroxide 392mol) dropwise under stirring, and finish adding within 30±5min; the second step: reflux condensation at atmospheric pressure Under the condition of 0.15Mpa or less than 0.15Mpa, heat the above reaction solution to 22±2°C, 27±2°C, 32±2°C respectively under stirring, keep warm for 0.5~1h each, and then heat it at 37±1°C Mature for 7 hours; the third step: distill the reaction solution under...

Embodiment 2

[0027] In conjunction with accompanying drawing, the embodiment of the preparation method of cationic monomer dialkyl disubstituent allyl ammonium halide of the present invention is: the first step: in the 0.12m that is equipped with reflux condensing device 3 In the enamel or stainless steel reaction kettle, pump in 99% (mass fraction, the same below) industrial chloropropene 32.5±0.1kg (chloropropene 392mol), 40% diethylamine aqueous solution 35.5±0.1 (diethylamine 200mol) under stirring , deionized water 1.8±0.1kg (100mol), slowly add 30% sodium hydroxide aqueous solution 24.5±0.1kg (sodium hydroxide 392mol) dropwise under stirring, and add it within 40±5min; the second step: reflux condensation under normal pressure conditions Under the condition of sealing at or lower than 0.15Mpa, the above reaction solution was heated to 22±2°C, 27±2°C, 32±2°C under stirring respectively, kept for 1h each, and then matured at 38±1°C for 7h; Step 3: Distill the reaction solution under re...

Embodiment 3

[0029] In conjunction with accompanying drawing, the specific embodiment of the preparation method of cationic monomer dialkyl disubstituent allyl ammonium halide of the present invention is: the first step: in the 0.12m that is equipped with reflux condensing device In enamel or stainless steel reactor, Under stirring, pump in about 99% (mass fraction, the same below) of 38.5 ± 0.1kg of industrial 2-methylchloropropene (392mol of 2-methylchloropropene), 21.8 ± 0.1kg of 40% dimethylamine aqueous solution (dimethyl Amine 200mol), deionized water 2.70±0.1kg (water 150mol), slowly add 30% sodium hydroxide aqueous solution 24.5±0.1kg (sodium hydroxide 392mol) dropwise under stirring, and add within 50±5min; the fifth step: reflux Under the condition of condensing normal pressure or under the sealed condition of less than 0.15Mpa, the above reaction solution was heated to 22±2°C, 27±2°C, 32±2°C respectively under stirring, kept for 1 hour each, and then heated at 39±1°C Mature for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com