Self-repairing microcapsule, preparation method and application thereof

A technology of self-healing microcapsules and capsules, which is applied in the direction of microcapsule preparations and microsphere preparations. It can solve the problems of affecting the yield of capsules, affecting material properties, and long reaction time, and achieves excellent emulsification, dispersion, and stabilization effects. Synthesis The method is simple and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]Preparation of microcapsules with self-healing properties. The core material of the microcapsule particles and the shell of the microcapsule, that is, the ratio of the total mass of the core material of the microcapsule to the total mass of the shell material is the core-wall ratio of the microcapsule. Example 1 provides the ratio of raw materials for preparing microcapsules, and the core-to-wall ratio of the microcapsules is 4. Shown in raw material proportioning table 1 (the used raw material of this embodiment is all direct manufacturer's purchase):

[0046] Table 1 Embodiment 1 raw material ratio

[0047] raw material

Content by weight / part

epoxy resin

10

1.3

n-Butyl glycidyl ether

1.8

1

3.4

0.1

7

Deionized water

40

[0048] The preparation process is as follows:

[0049] (1) take eac...

Embodiment 2

[0058] Example 2 provides the raw material ratio of the microcapsules with a core-to-wall ratio of 3, as shown in Table 2, and the preparation process is the same as that of Example 1.

[0059] Table 2 Embodiment 2 raw material ratio

[0060] raw material

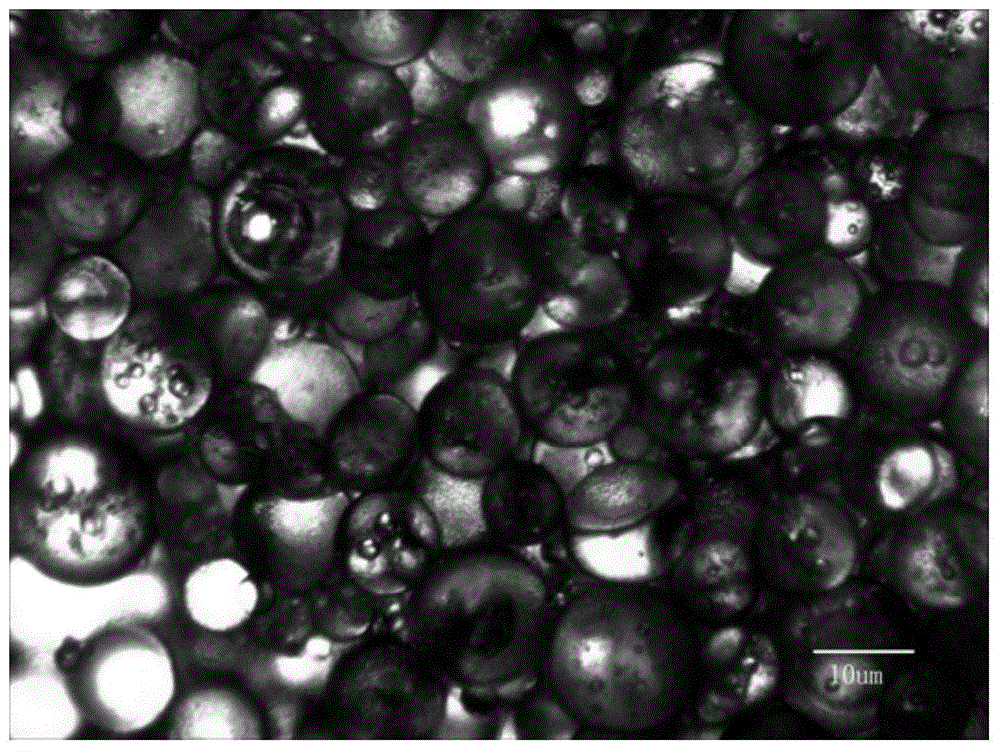

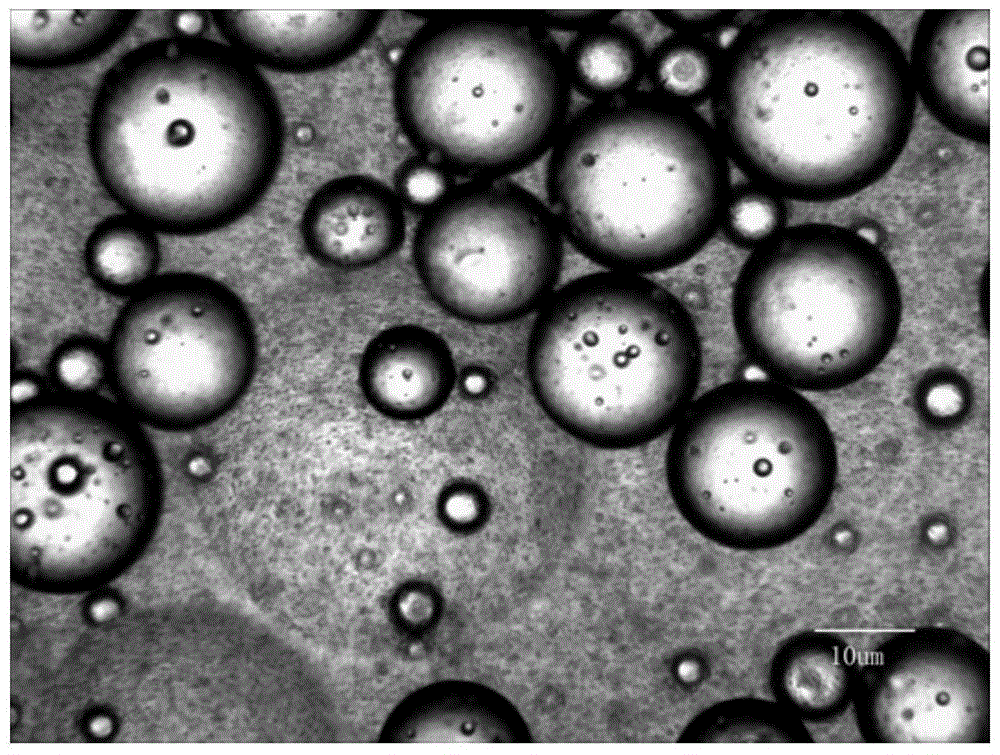

[0061] Observation results of the obtained compound capsule wall microcapsules prepared in this example through an optical microscope show that the dispersibility is good. When the core wall of the microcapsule is relatively small, its distribution density decreases, and the particle size distribution is not uniform at the same time.

Embodiment 3

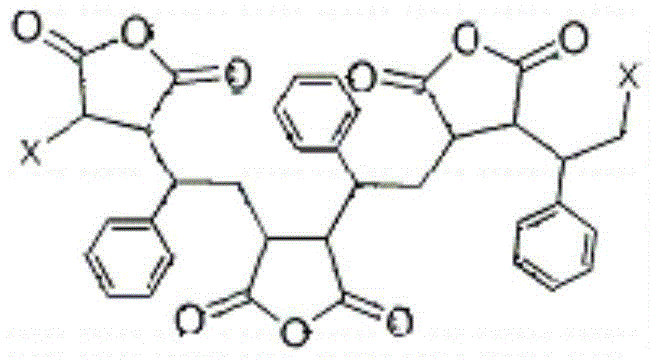

[0063] A self-healing microcapsule, the capsule includes a capsule core and a complex wall coated on the outer surface of the capsule core, the capsule core is a repairing agent, and the complex wall is made of styrene-maleic anhydride and gelatin It is formed in combination, wherein the mass ratio of the restoration agent to styrene-maleic anhydride and gelatin is 5:2:1.

[0064] In this embodiment, the restorative agent is methyl methacrylate, and the specific preparation method includes the following steps:

[0065] (1) Dilute the restorative agent with a diluent to prepare a diluted repair agent solution;

[0066] (2) adding styrene-maleic anhydride to the alkali solution, heating, stirring to make it hydrolyzed, adjusting the pH value to 5, and obtaining a light yellow transparent solution;

[0067] (3) Warm up the light yellow transparent solution prepared in step (2) to 60°C, stir and disperse for 10 minutes, then add the dilute solution of restoration agent prepared i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com