Grinding device for grinding glass end surface

An end face and glass technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine parts, etc., can solve the problems of low degree of automation, affecting personal safety, unsightly glass, etc., to reduce cleaning The amount of work, work efficiency and quality are high, and the effect of reducing the work load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the preferred embodiments of the present invention will be further described below in conjunction with the description of specific embodiments and drawings.

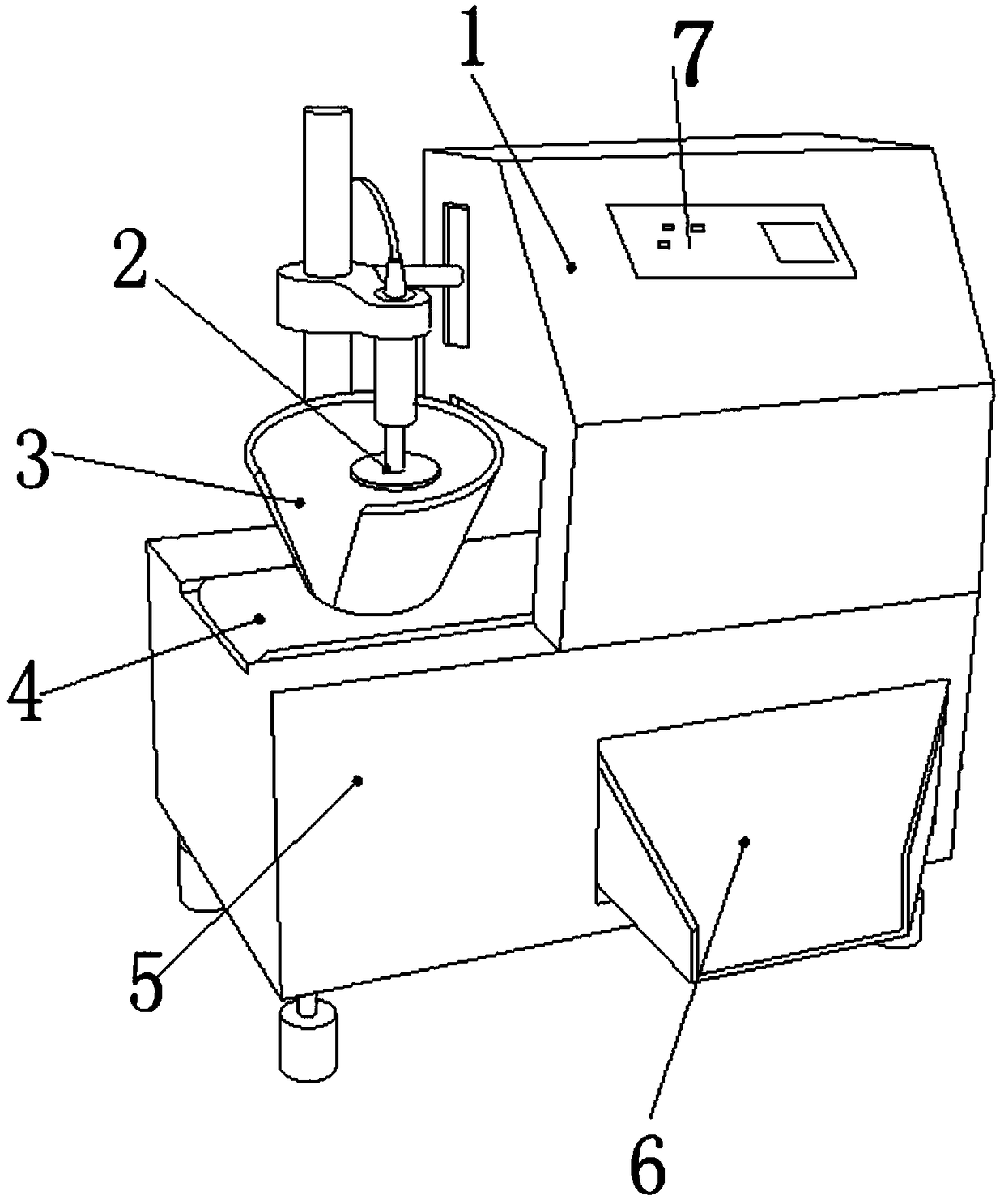

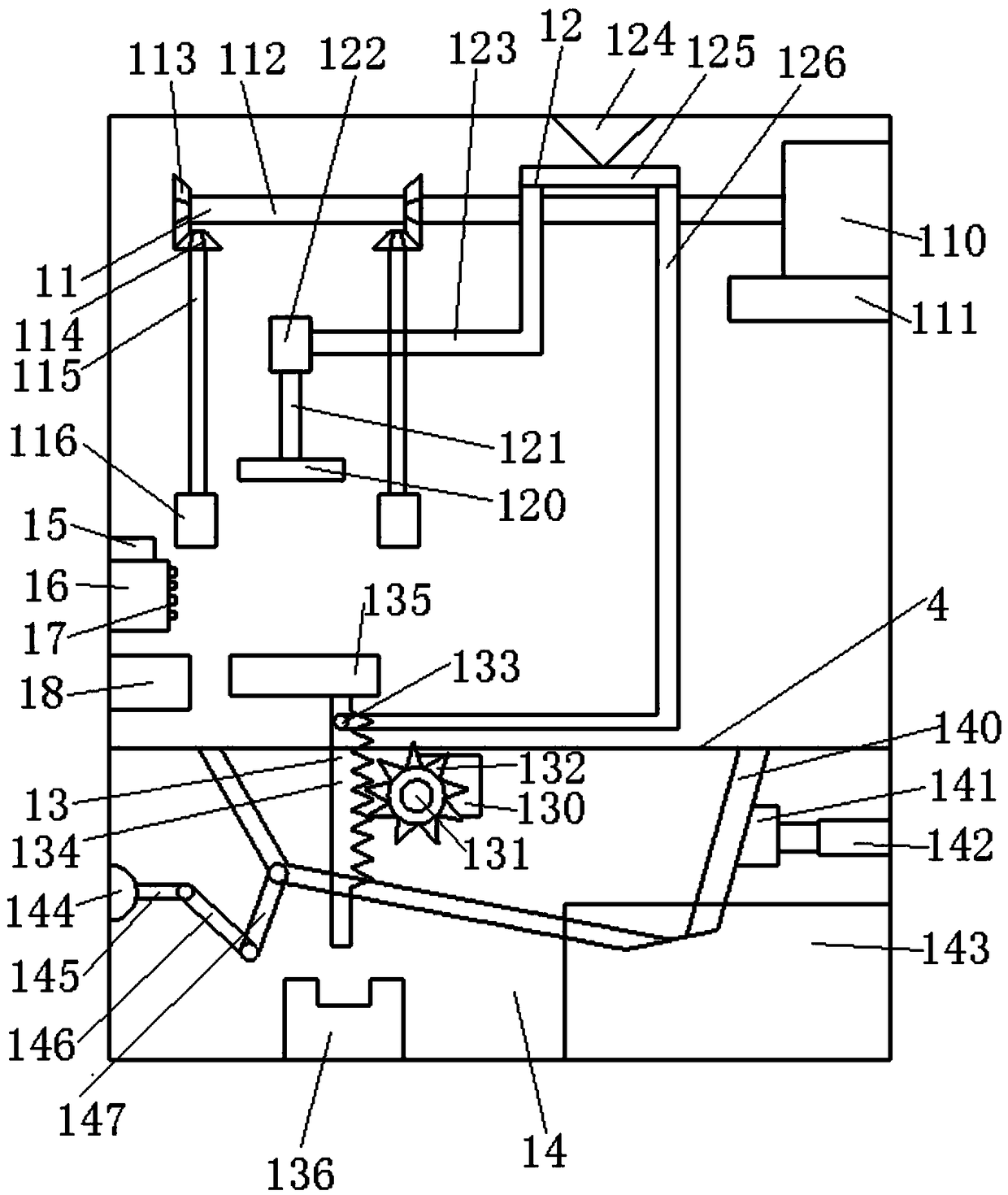

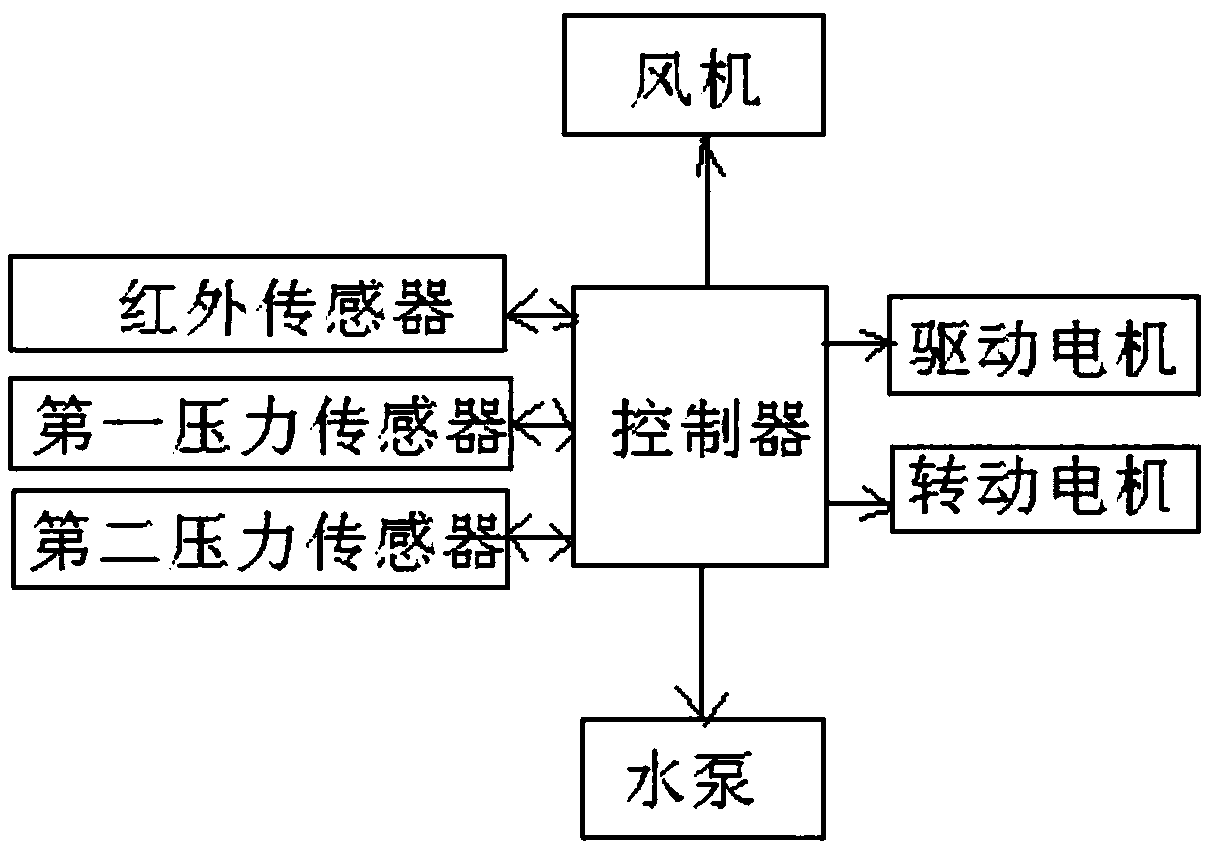

[0019] A polishing device for polishing the end surface of glass, comprising an end surface polishing device 1, a cutting knife 2, a chip collection chamber 3, a transmission belt 4, a casing 5, a slag output channel 6, a control panel 7, and the end surface polishing device 1 is arranged in the casing 5. The end surface grinding device 1 is provided with a crushed slag output channel 6, the shell 5 is provided with a chip collection cavity 3, the chipping knife 2 is installed in the chip collection cavity 3, and the chip collection cavity 3 is provided with a transmission belt 4 and a transmission belt 4 It is connected with the end face grinding device 1, and the end face grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com