Automatic PI film cutting machine

A film cutting machine, automatic technology, applied in electrostatic, metal processing, electrical components and other directions, can solve the problems of high production cost, low efficiency, discontinuity, etc., to improve quality and work efficiency, reduce production cost, improve film cutting quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

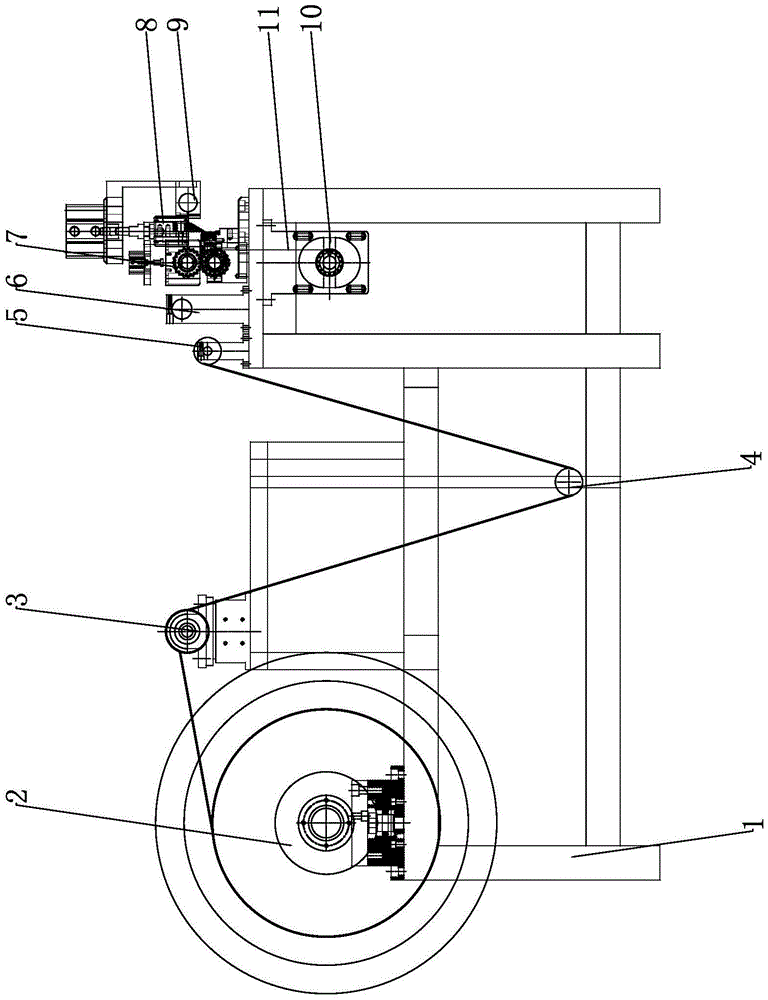

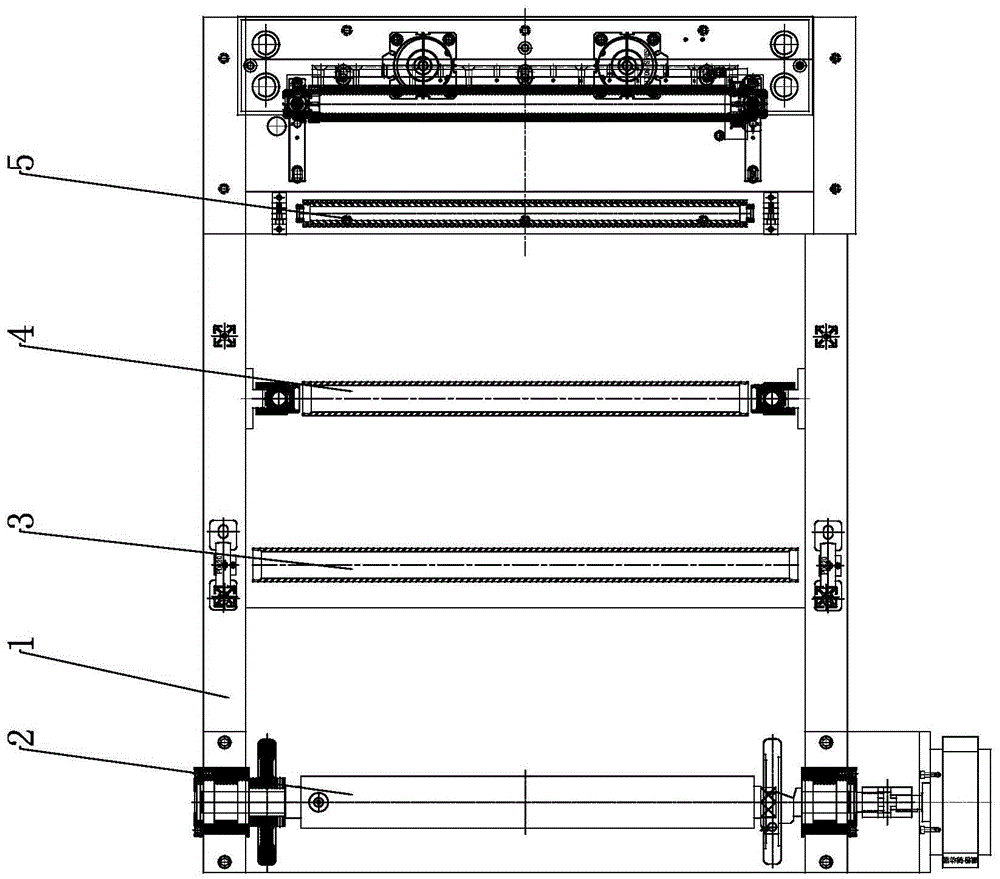

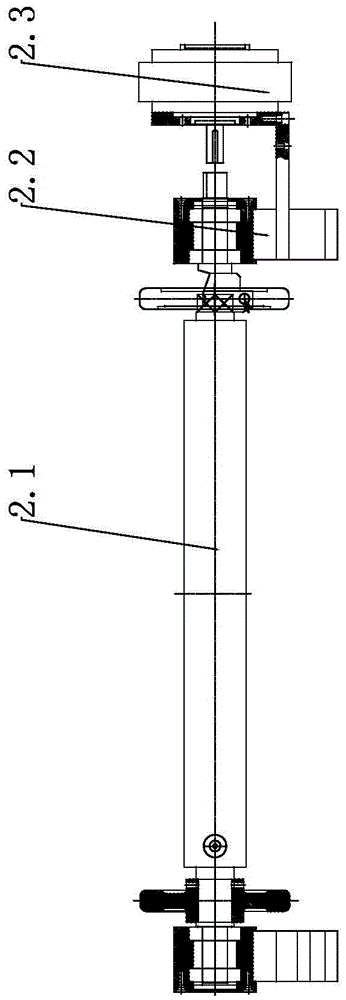

[0019] Such as Figure 1~2 As shown, the present invention mainly includes a main support 1, a feeding device 2, a tension detector 3, a buffer roller 4, a gear conveying device 7, an upper and lower cutter device 8 and a gear driving device 10.

[0020] The main support 1 is provided with a discharge device 2, a tension detector 3, a buffer roller 4, a gear conveying device 7, and an upper and lower cutter device 8 from left to right, and an antistatic device is installed between the buffer roller 4 and the gear conveying device 7. Pass the wheel 5 and the first antistatic bar 6, and the rear end of the upper and lower cutter device 8 is provided with a second antistatic bar 9.

[0021] The lower end of the gear conveying device 7 is provided with a gear driving device 10 , and the gear driving device 10 is connected to drive the gear conveying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com