Automatic traveling speed control device of gluing machine and gluing machine with same

A gluing machine and gluing machine technology, applied in the weaving industry, can solve problems such as low product output, low production efficiency, and difficulty in ensuring product quality, and achieve the goals of improving quality and work efficiency, high precision, and saving manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention will be further described in detail with the actual gluing situation of two different gluing materials 1, 2 below.

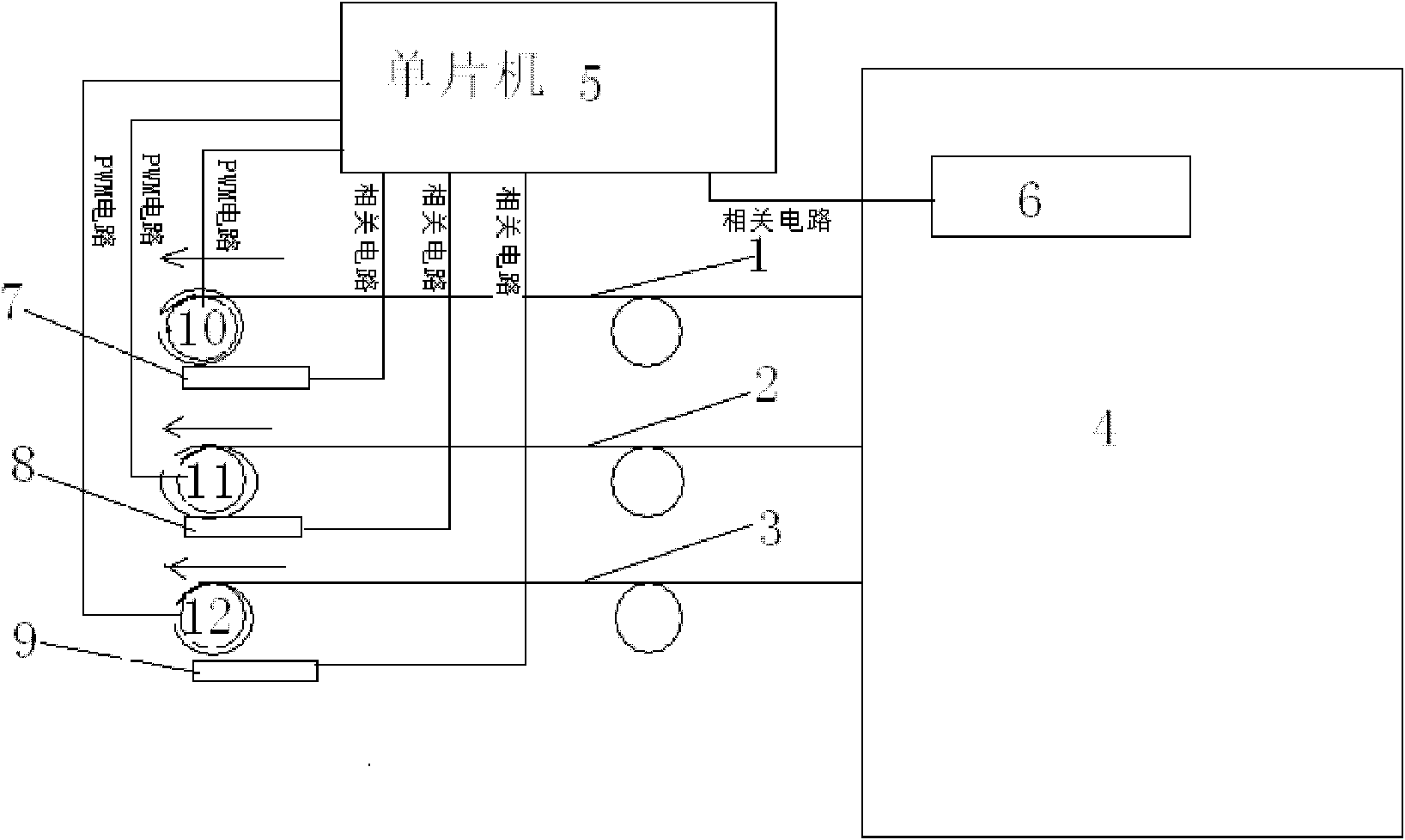

[0026] Before all the work starts, pre-set the tested data that can achieve the best working effect into the single-chip computer system, and the gluing machine starts to work. First, the temperature sensor 6 measures the glue temperature of the gluing machine, which is displayed as 130 degrees by the single-chip microcomputer. The rotational speed sensor 7 measures the rotational speed of the reel motor 10, which is displayed as 2 r / min by the single-chip microcomputer. The rotational speed sensor 8 measures the reel motor 11. The rotating speed of the single-chip microcomputer is 1.3r / min, but for the material 1 when the glue temperature is 130 degrees, the optimal speed of the winding reel motor 10 should be 1.8r / min, and the material 2 is when the glue temperature is 130 degrees. The optimal speed of winding reel motor 11 should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com