Cutter for marten processing

A cutting knife and mink fur technology, applied in the field of mink fur processing cutting knives, can solve the problems of reducing the quality of mink fur, easily cutting off the hair, and deteriorating the mink fur, etc. The effect of improving heat retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

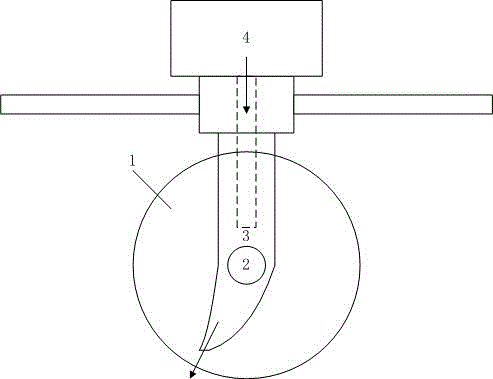

[0025] The mink fur processing cutter of the present embodiment, structural representation is as figure 1 shown. The mink fur processing cutter comprises a disc-shaped blade 1, a rotating shaft 2 passing through the center of the blade 1, and a fork 3 capable of horizontal movement is installed on the rotating shaft 2;

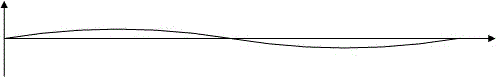

[0026] The blade portion of the blade 1 develops a sinusoidal curve along the circumferential direction, such as figure 2 Shown; The cycle T of described sine curve is:

[0027] T=2πr / n

[0028] Wherein, r is the radius of the blade 1, and n is a non-zero natural number; the period T of the sinusoidal curve is greater than 20 times the amplitude;

[0029] Described fork 3 passes rotating shaft 2 and protrudes forward, and the front end of fork 3 is provided with exhaust hole, and described exhaust hole is supplied with air by air pump 4, and the air blowing direction of exhaust hole is in the plane of blade 1, for from Rotate clockwise from 10 degrees to ...

specific Embodiment 2

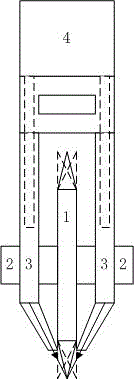

[0032] The mink fur processing cutter of the present embodiment, structural representation is as Figure 4 shown. This mink fur processing cutter, on the basis of the specific embodiment one, further defines that the front of the blade 1 is provided with a "concave" shaped heater 5, and the blade 1 stretches into the breach of the heater 5, as Figure 5 As shown; inside the heater 5, a heating wire is provided, and the blade 1 is heated by energizing the heating wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com