Gapless shearing ceramic crushing, dispersing, homogenizing and emulsifying device

A homogeneous emulsification, gap-free technology, applied in grain processing and other directions, can solve problems such as low work efficiency, improve quality and work efficiency, and increase processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

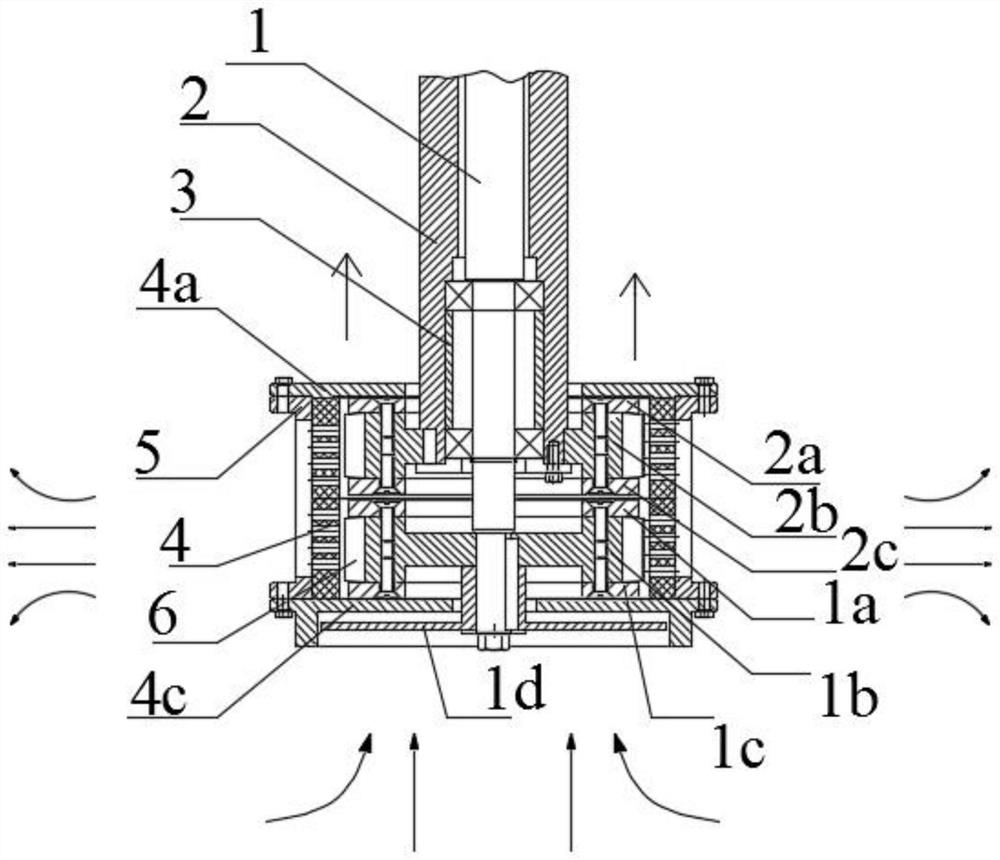

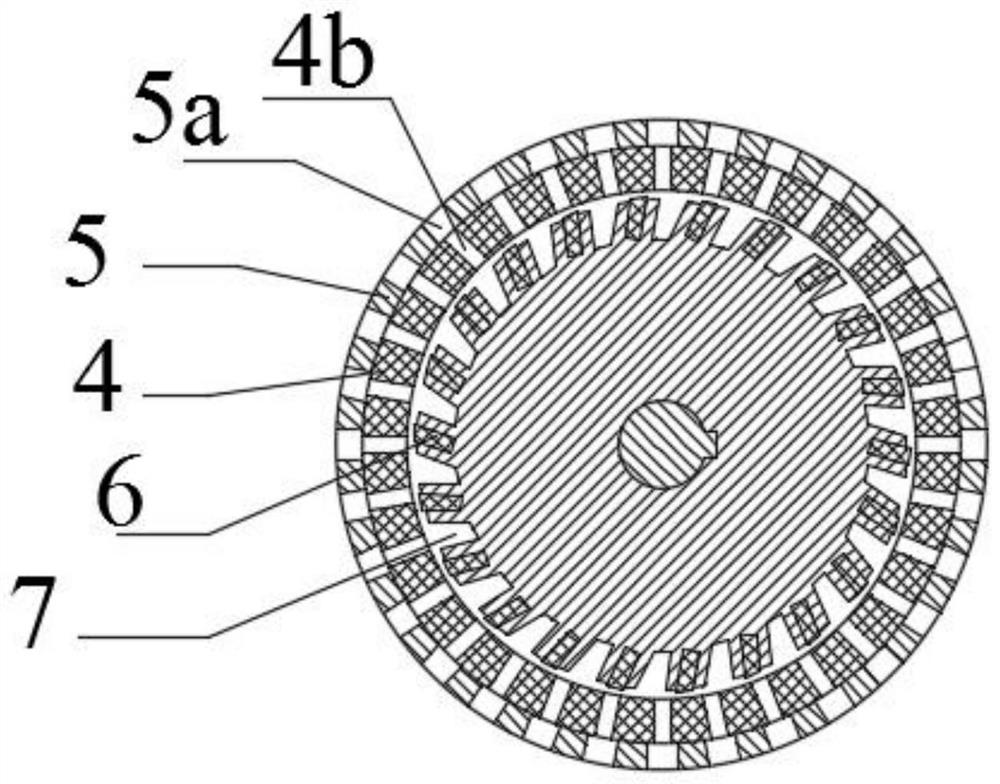

[0029] like figure 1 As shown, a gapless shearing ceramic pulverizing and dispersing homogeneous emulsification device is disclosed in this embodiment, which includes a homogenizing shaft, a stator housing 5 sleeved at one end of the homogenizing shaft, and a stator housing 5 installed in the stator housing 5 A stator ring 4, and a rotor cutter head mounted on one end of the homogeneous shaft and located in the stator ring 4;

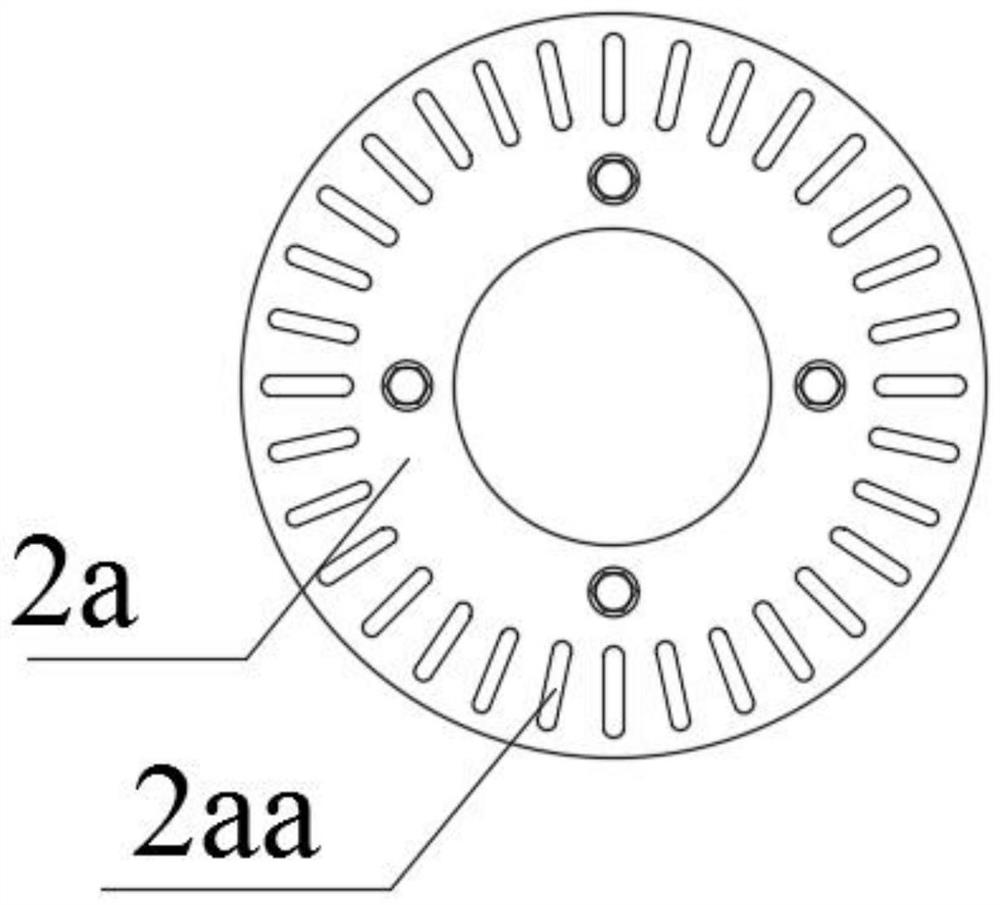

[0030] The homogeneous shaft includes a forward rotor shaft 1 and a reverse rotor shaft 2 sleeved outside the forward rotor shaft 1 through a bearing spacer 3; in this embodiment, the forward rotor shaft 1 is longer than the reverse rotor shaft 2 ; At the lower end of the forward rotor shaft 1 and extending out of the stator housing 5, a suction stirring disc 1d is installed;

[0031] On the forward rotor shaft 1 and located inside the stator ring 4, a forward cutterhead 1b is installed; The cover plate 1a and the lower cover plate 1c of the cutter he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com