Ship unloading and loading control system and related system and device

A ship control system and control system technology, applied in the field of intelligent control, can solve the problems of high labor cost, low operating efficiency, and low degree of intelligence, and achieve the goals of improving operating efficiency, reducing human resource investment, and reducing human engineering cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

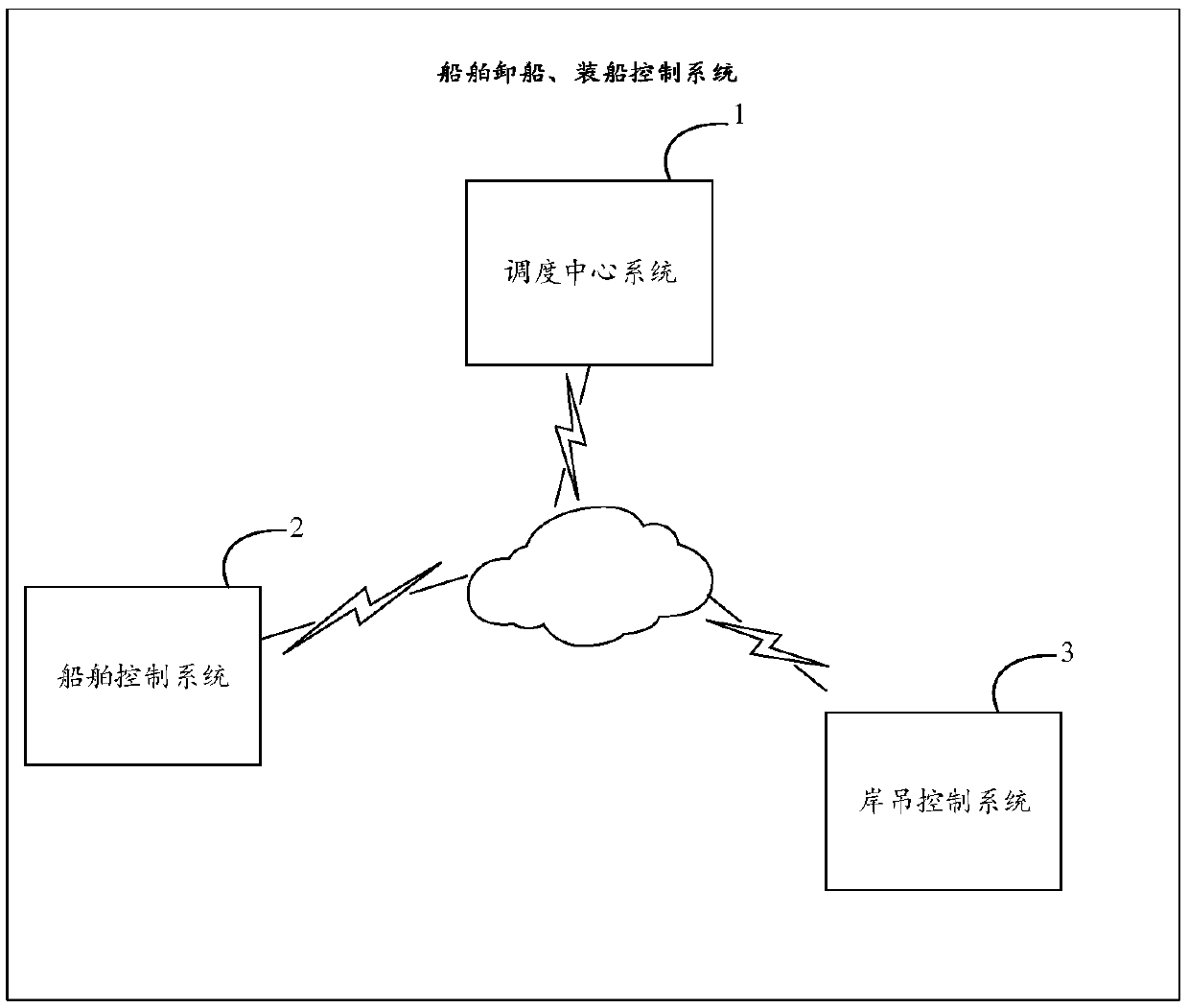

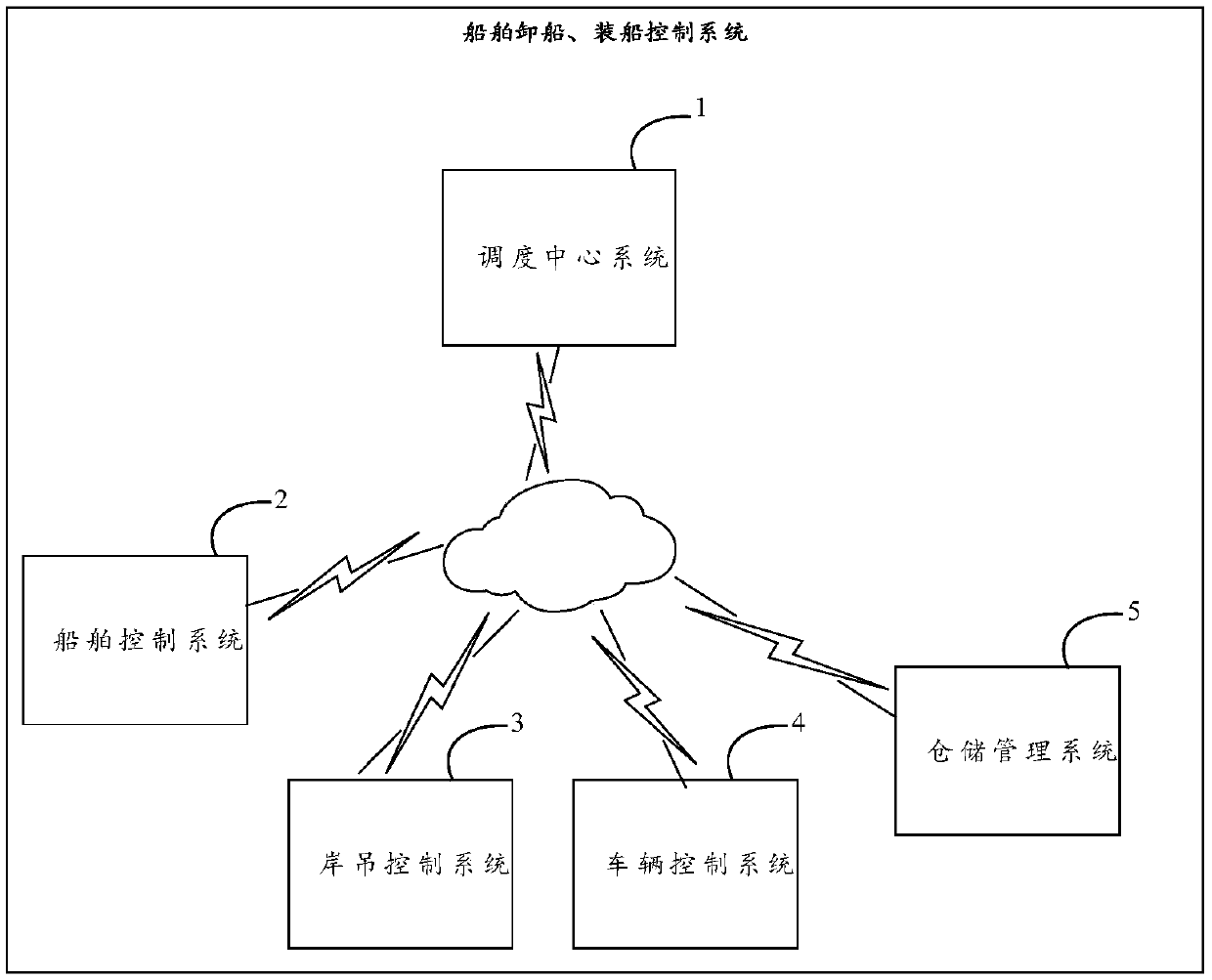

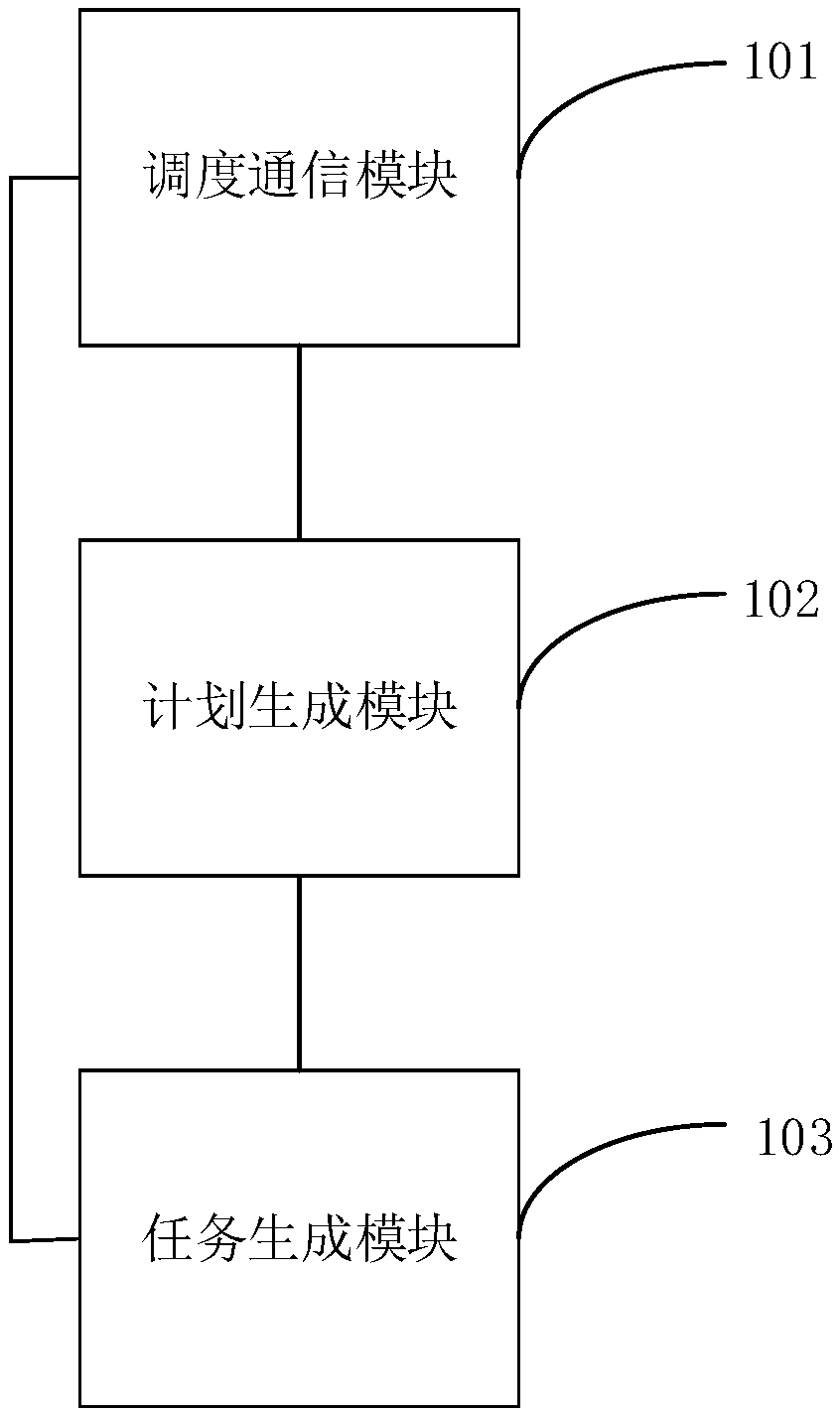

[0033] like figure 1 As shown, it is a schematic structural diagram of the ship unloading control system provided by Embodiment 1 of the present invention. The ship unloading control system includes a dispatching center system 1, a ship control system 2 installed on the ship, and a shore crane control system installed on the shore crane equipment. System 3, where:

[0034] The dispatching center system 1 is used to generate a ship unloading plan according to the ship information of the target ship, container information, and shore crane equipment information; generate a berthing task and a ship unloading task according to the ship unloading plan, and combine the berthing task, unloading task, and Ship tasks are sent to the ship control system 2 of the target ship and the shore crane control system 3 of the target shore crane equipment (that is, the dispatch center system 1 sends the ship berthing task to the ship control system 2 of the target ship, and sends the ship unloadin...

Embodiment 2

[0121] Embodiment 2 of the present invention also provides a ship loading control system, referring to figure 1 shown, including:

[0122] The dispatching center system 1 is used to determine the shipping plan according to the ship information, container information and shore crane equipment information; generate a berthing task and a shipping task according to the shipping plan, and separate the berthing task and the shipping task Send to the ship control system 2 of the target ship, the shore crane control system 3 of the target shore crane equipment (that is, the dispatching center system 1 sends the berthing task to the ship control system 2 of the target ship, and sends the loading task to the target shore crane equipment shore crane control system 3);

[0123] The ship control system 2 is used to control the target ship to travel to the operation area corresponding to the target shore crane device when receiving the berthing task, and send a ship in place notification m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com