Intelligent lighting automatic detection and analysis system and detection method thereof

An automatic detection and analysis system technology, applied in the direction of optical instrument testing, measuring devices, testing optical performance, etc., can solve problems such as lack of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

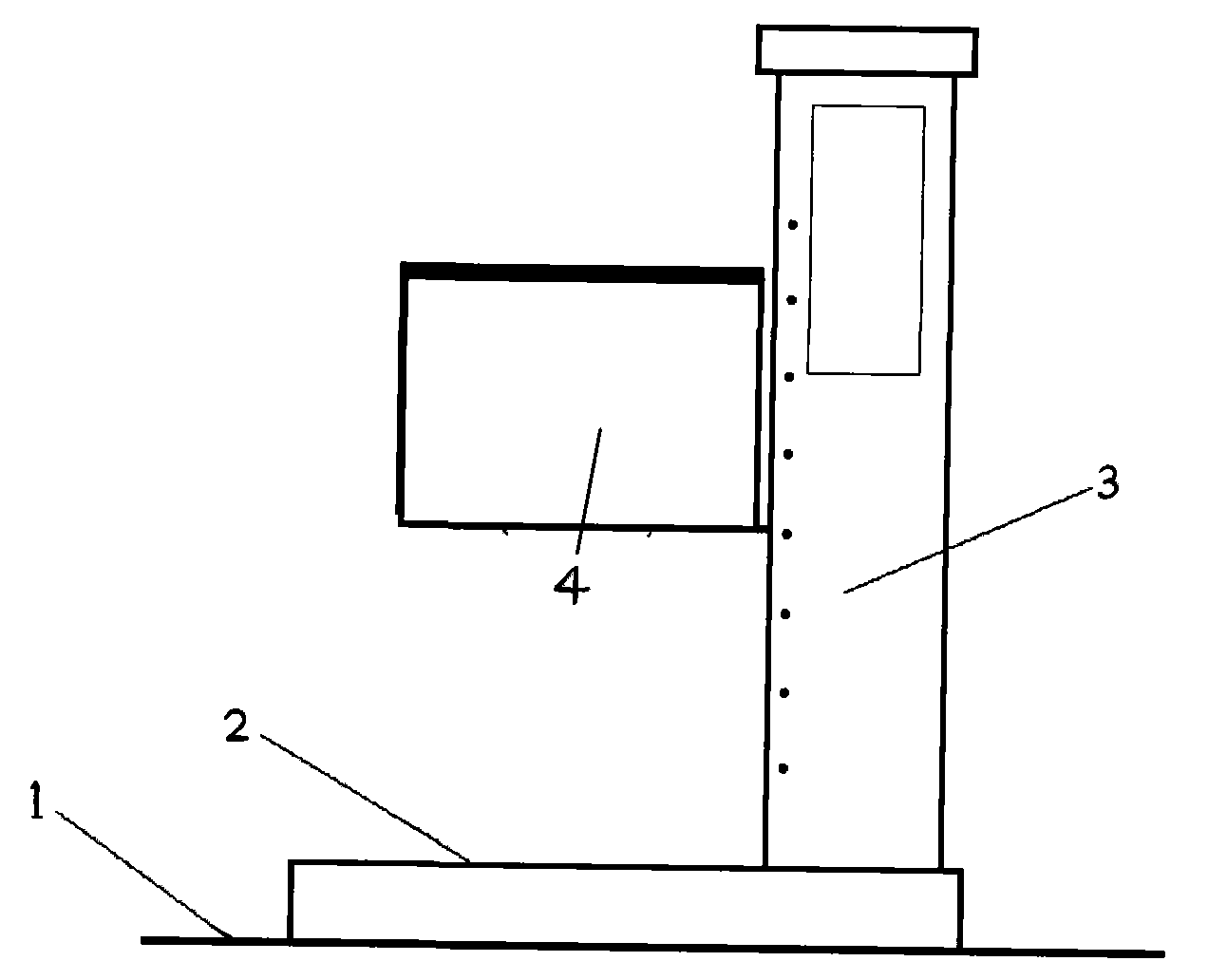

[0026] The specific implementation manners, structures, features and functions provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

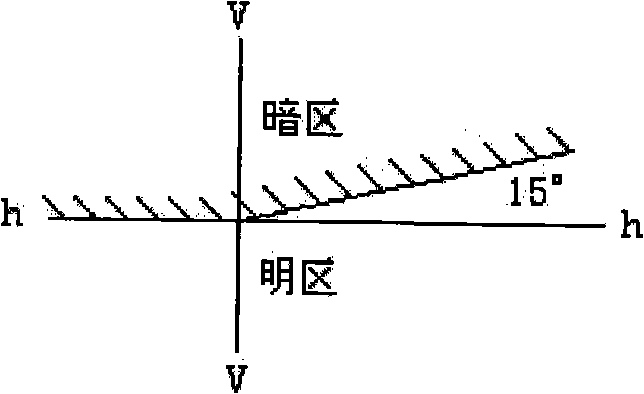

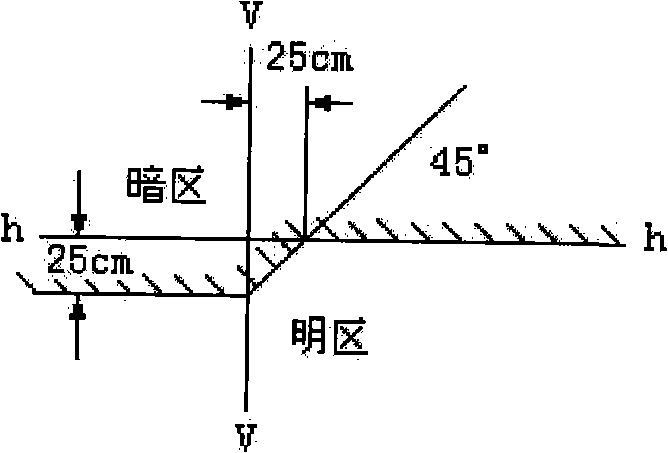

[0027] see Figure 2~3 , an intelligent lighting automatic detection and analysis system, comprising a guide rail 1, a base trolley 2, a column 3, a light receiving box 4, an optical system, a CCD camera, a single-chip processing system 10 and a DSP image processing system 11, and the base trolley is equipped with The guide rail and the column are installed on the base trolley, and the light receiving box is installed on the column. The light receiving box is equipped with a Finsier lens 5, two CCD cameras 6, 7, an imaging screen 8 and a light metering strong light battery sensor 9; the Fresnel lens It is used for high-beam or low-beam imaging. One of the CCD cameras 6 is used to aim at the luminous motor vehicle headlights; the other CCD camera 7 uses a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com