Automatic storage system for drill stem

An automatic access and drill pipe technology, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve the problems of low precision, difficult control, and many working stations of the grasping mechanism, so as to improve work efficiency and realize automation Control, large volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

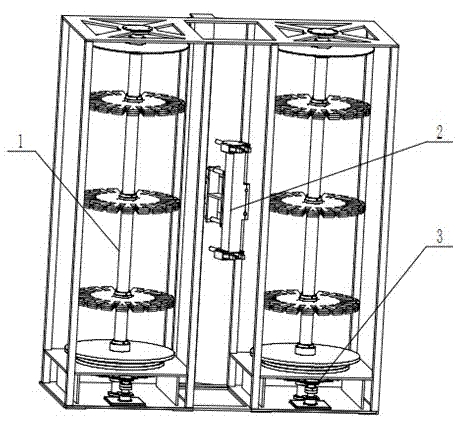

[0035] The structure of a drill pipe automatic access system of the present invention is as follows: figure 1 As shown, in the present invention, there are two drill rod magazines 1, the grabbing mechanism 2 is installed on the support beam between the left and right drill rod magazines, and the drive mechanism 3 is at the bottom of the drill rod magazine.

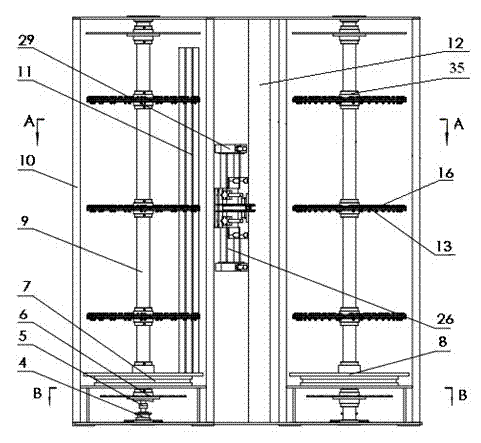

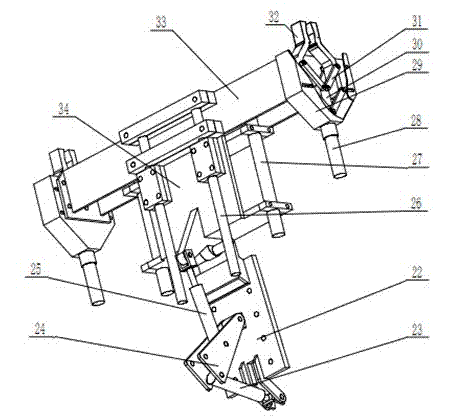

[0036] figure 2 , 3 , 5 and Figure 7 As shown, the drill rod magazine 1 is composed of a thrust bearing 7, a pallet 8, a main shaft 9, a frame 10, a support beam 12, a lower chuck 13, a draw groove 14, a gasket 15, a chuck surface 16, a bolt A17, a screw Composed of a hub 35, the frame is a rectangular frame with a protruding frame, the left and right drill rod storages are arranged on both sides of the rectangular frame, and the hydraulic motor 4 of the driving mechanism is installed at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com