Remote-control underground gas extraction drilling machine

A technology of gas drainage and remote control, which is applied in the direction of electrical program control, gas discharge, program control in sequence/logic controller, etc. It can solve the problems of loss of life and property, prone to explosion, gas explosion, etc., to ensure life Safe, guaranteed reliable operation, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

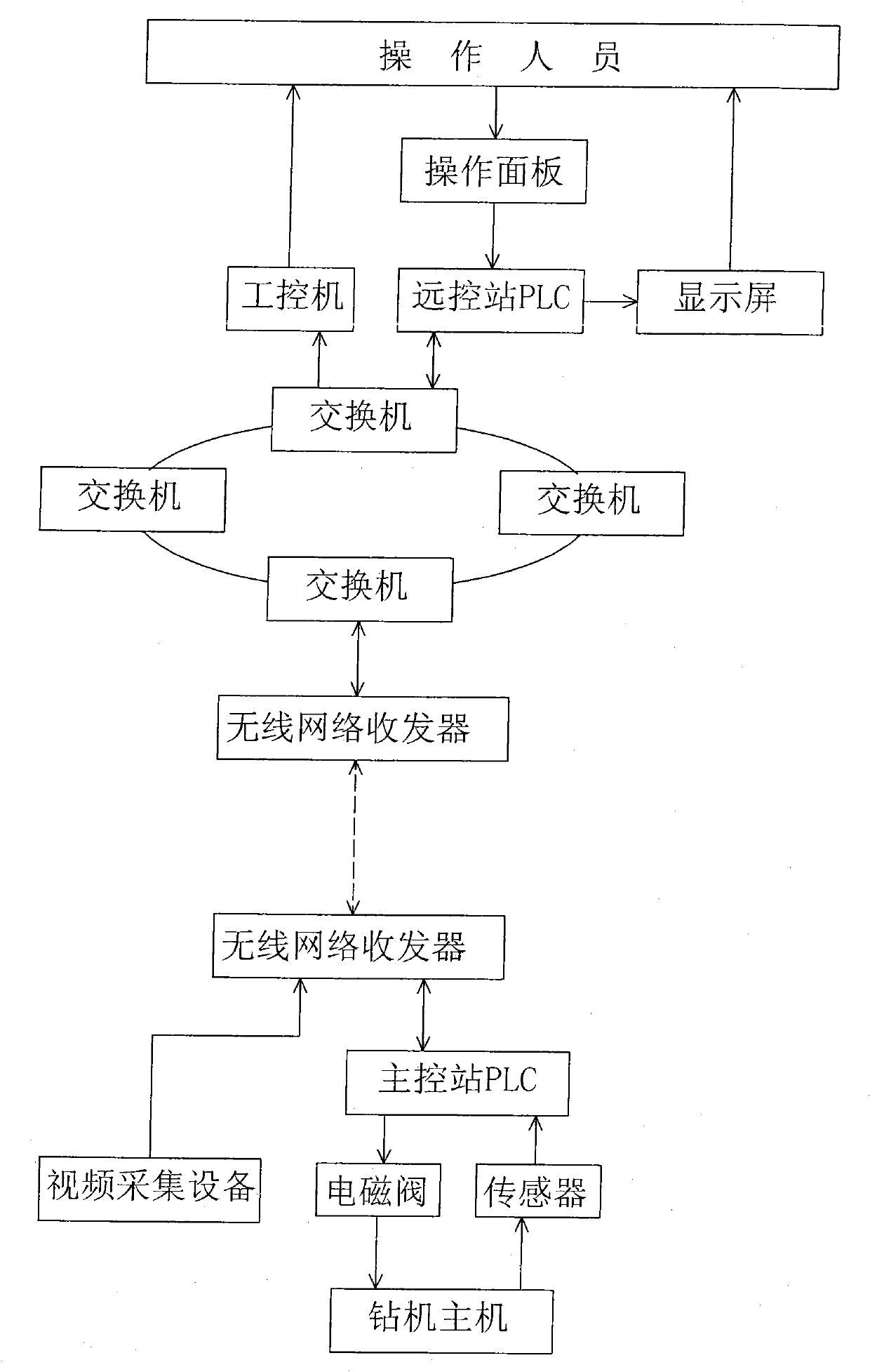

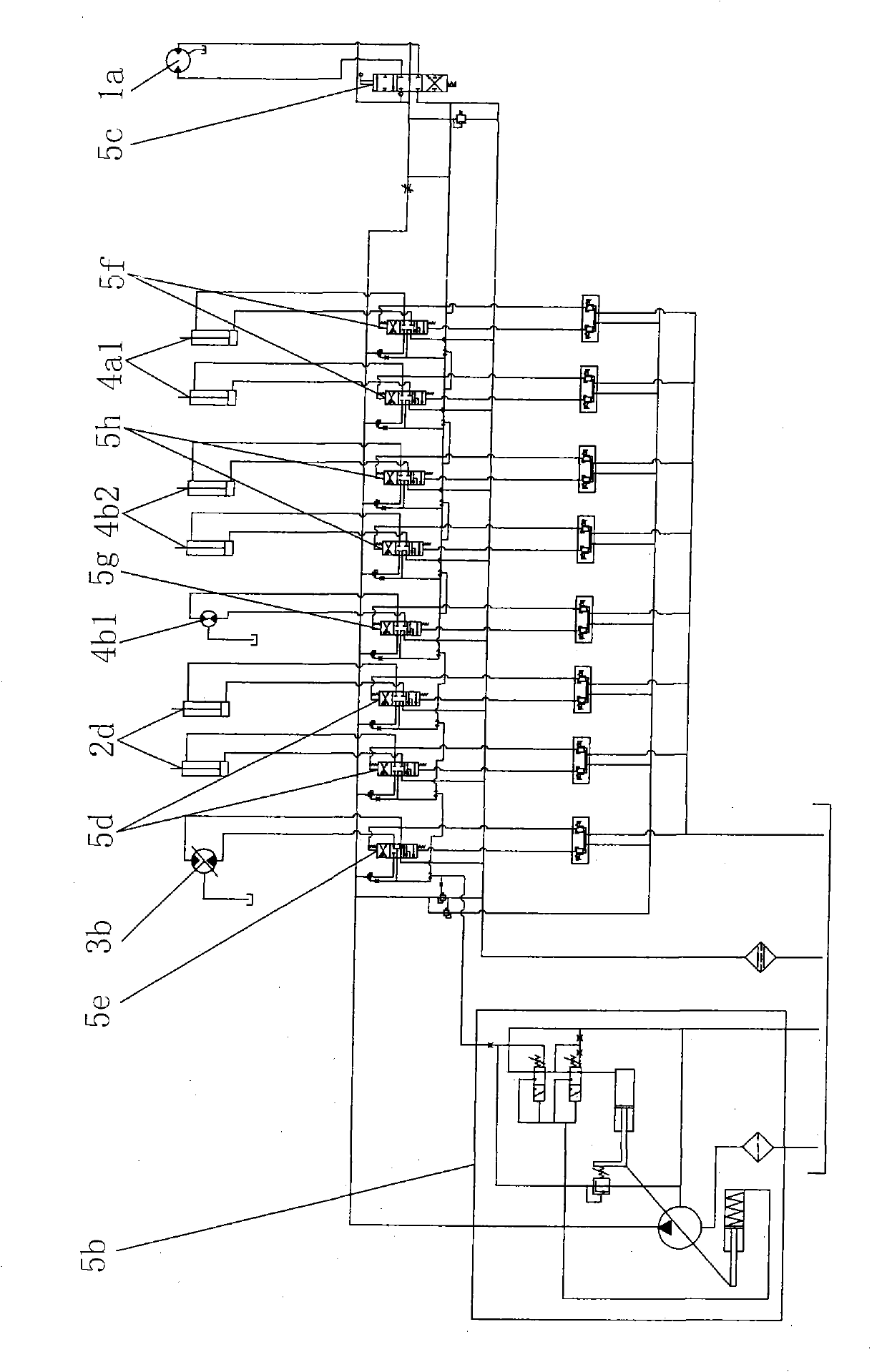

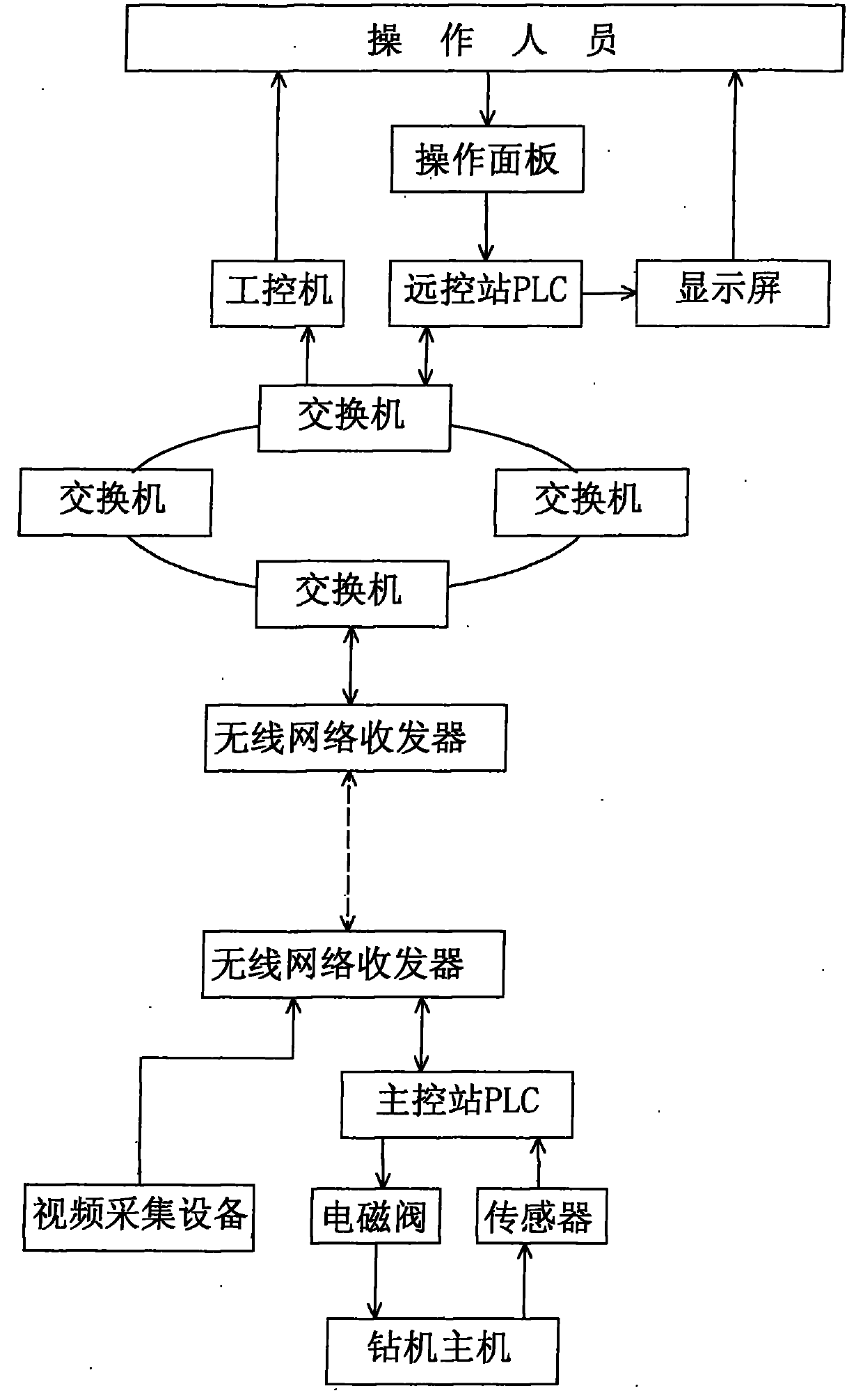

[0031] figure 1 Schematic diagram of the electric control system; figure 2 It is the main view of the drilling machine; image 3 for figure 2 A-direction view; Figure 4 It is the front view of the propulsion unit; Figure 5 for Figure 4 B direction view; Image 6 Schematic diagram of the power head structure; Figure 7 It is a schematic diagram of the power components of the hydraulic pump station; Figure 8 Schematic diagram of the hydraulic system.

[0032] As shown in the figure, the remote-controlled underground gas drainage drilling rig of the present invention includes a main engine of the drilling rig and an electric control system for controlling the operation of the main engine of the drilling rig; A communication device for transferring information between them;

[0033] The master control station includes:

[0034] a. The main control station PLC is used to transmit the information from the main engine of the drilling rig to the remote control station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com