Automatic grabbing carrying device

A handling device and automatic technology, which is applied in the direction of transportation and packaging, trolley cranes, load hanging components, etc., to achieve the effect of low production costs, low skill requirements for workers, and automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

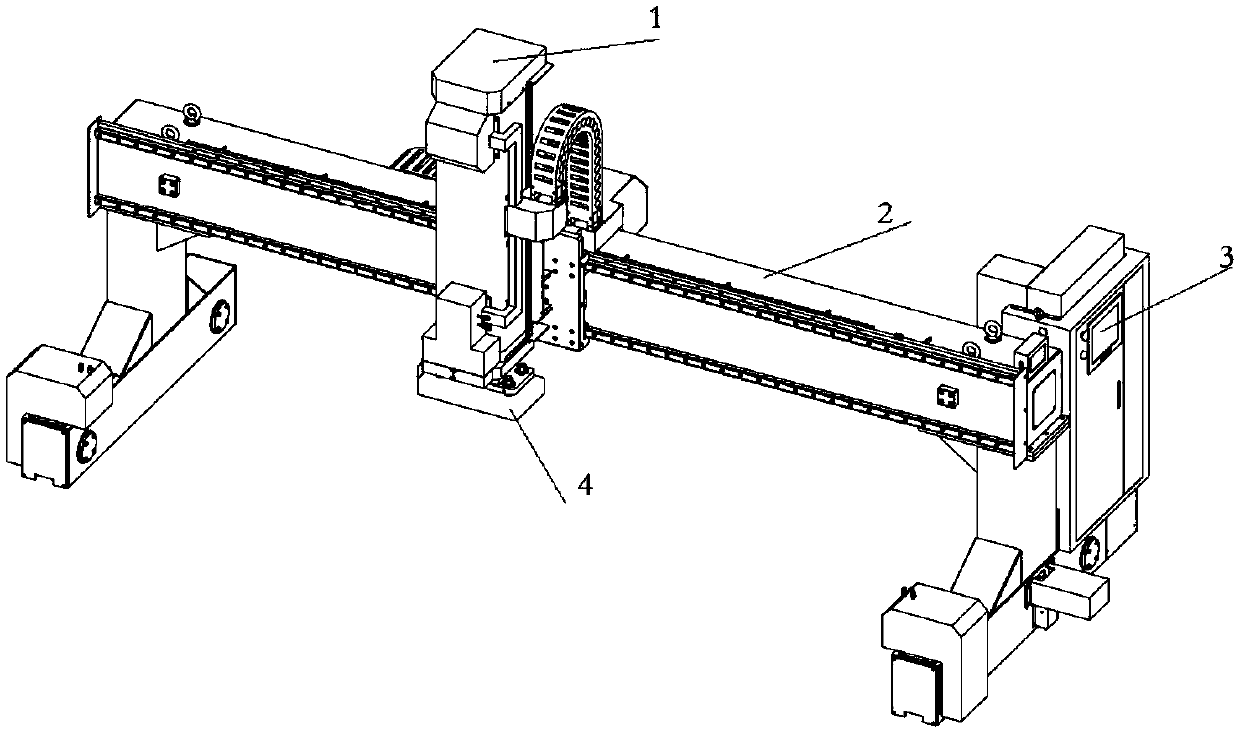

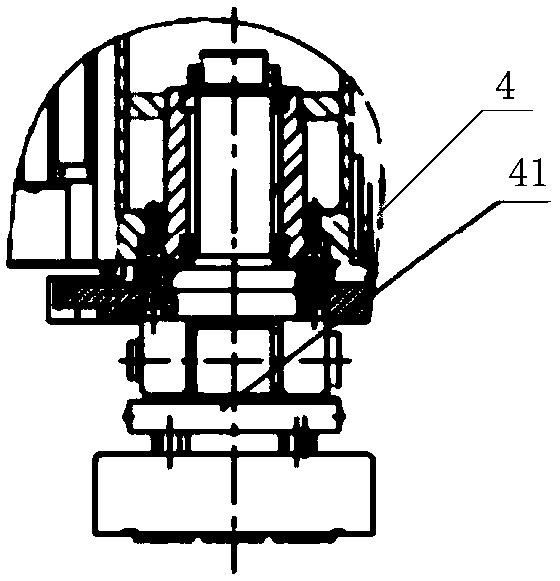

[0020] combine figure 1 , an automatic grabbing and handling device, comprising a grabbing and handling head 1, a handling gantry 2, an electric control cabinet 3, and an electromagnetic chuck 4. The grabbing and transporting head 1 is installed on the transporting gantry 2, the electric control cabinet 3 is installed on the transporting gantry 2, the electric control cabinet is installed on the transporting gantry, and the electric control cabinet controls the grabbing and transporting head on the transporting gantry To move horizontally and vertically; the electromagnetic sucker is installed on the grasping and conveying head 1, and the grasping and conveying head drives the electromagnetic sucker to grab the workpiece.

[0021] The handling gantry 2 is a low gantry structure, which is installed inside the welding robot gan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com