Method and device for preparing pinpoint of scanning tunnel microscope (STM)

A technology of scanning tunneling and microscopy, applied in scanning probe microscopy, scanning probe technology, measuring devices, etc., can solve the problem of expensive needle tip, and achieve the effect of simple device, easy implementation, and small radius of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

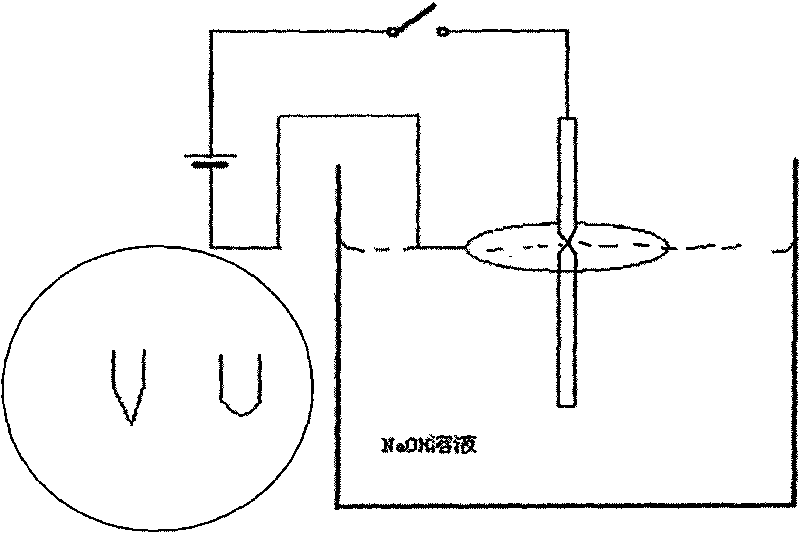

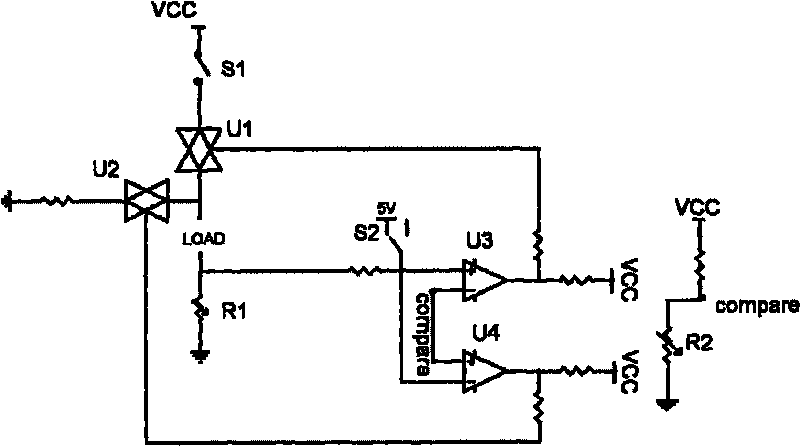

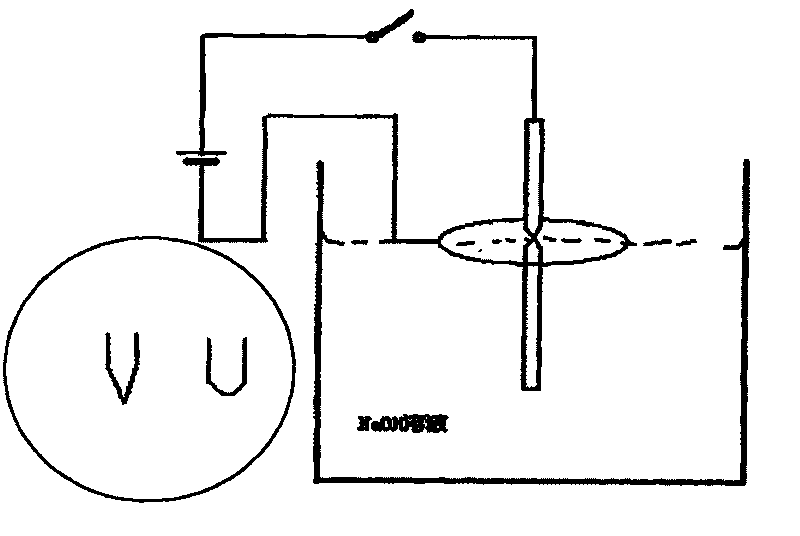

[0013] Such as figure 1 As shown, a copper electrode 1 as a cathode and a tungsten wire 2 as an anode are connected in NaOH solution 3 . After electrification, the electrochemical reaction at the anode is Wu=Wu 2+ +2e - or Wu=Wu 3+ +3e - , the electrochemical reaction at the cathode is 2H + +2e-=H 2 . In this way, the tungsten wire will be corroded in the solution. For some reason, the corrosion at the liquid surface of the solution will be very fast, so the tungsten wire at the liquid surface will become thinner and thinner and eventually break to form a needle tip. However, the circuit must be cut off at the moment when the tungsten wire is disconnected, otherwise the needle tip will become blunt due to continuous corrosion, so a voltage feedback circuit is needed to control the on-off of the circuit. The copper electrode of the cathode is ring-shaped, and the tungsten wire of the anode is placed at the center of the circle, which requires an instrument table to fix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com