LED lamp bead capable of replacing halogen lamp and manufacturing process thereof

A technology of LED lamp beads and halogen lamps, which is applied to parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of complex structure of G9 lamp beads, impossibility of touching with hands, and affecting luminous effect, etc., to achieve Lower temperature, avoid discoloration, good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

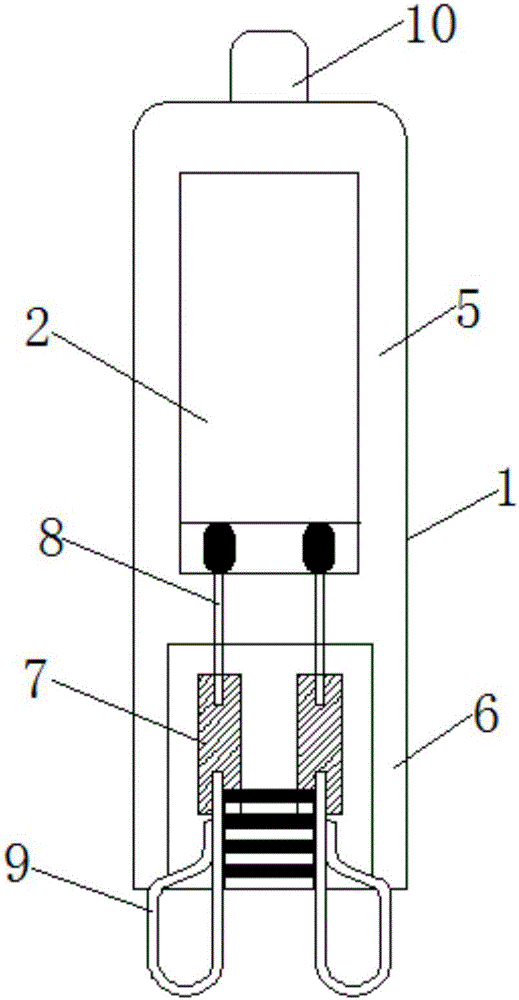

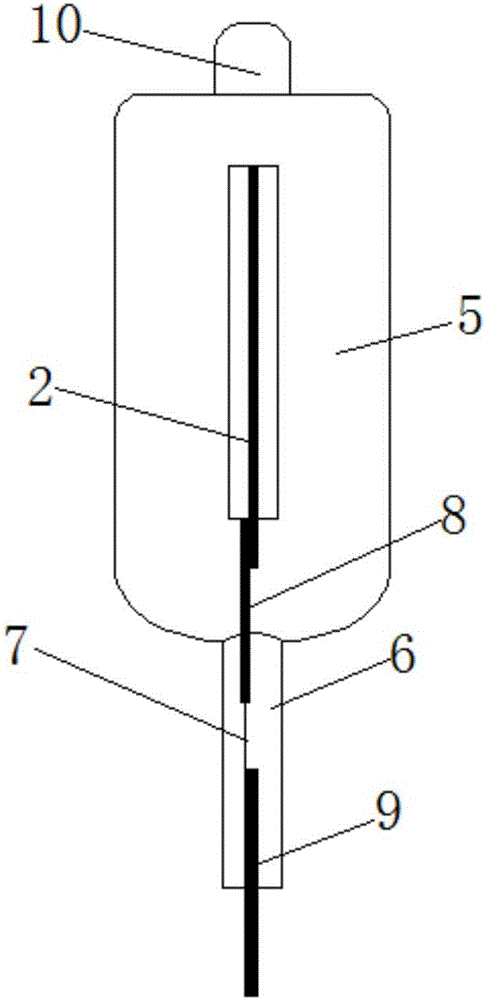

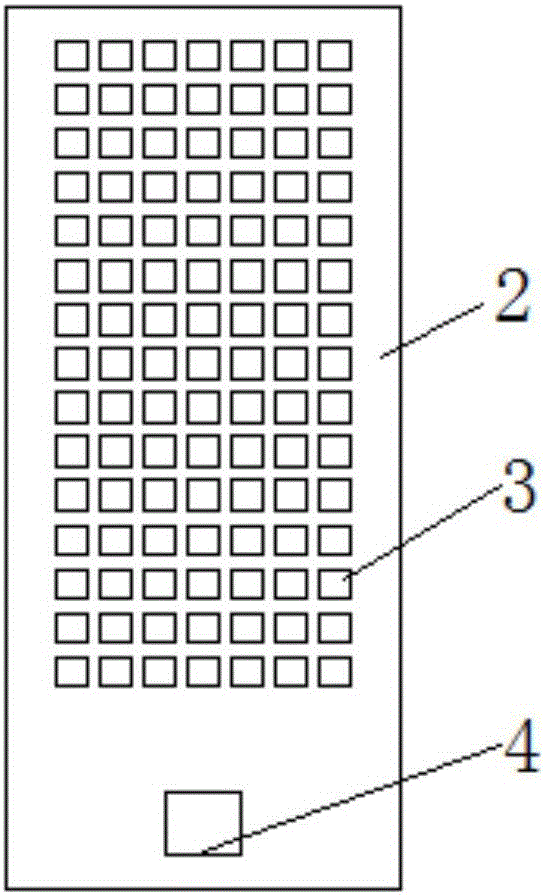

[0032] Such as Figure 1-3 As shown, an LED lamp bead that can replace a halogen lamp includes a housing 1, a substrate 2, several LED chips 3 and power components 4, the housing 1 is a glass housing, and the housing 1 includes a cylindrical upper part 5 and The flat lower part 6, the substrate 2 is arranged in the upper part 5, the LED chips 3 are evenly arranged on the front and back sides of the substrate 2, the power supply components 4 are arranged on the substrate 2, and the lower end of the substrate 2 A molybdenum sheet 7 is provided, and the molybdenum sheet 7 is connected to the substrate 2 through a molybdenum rod 8. The lower end of the molybdenum sheet 7 is provided with a pin 9, and the upper end of the pin 9 and the molybdenum sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com