Metal ultrasonic welding heat dissipation method and metal ultrasonic welding machine

A technology of ultrasonic welding and heat dissipation method, which is applied in the heat dissipation of metal ultrasonic welding and the field of metal ultrasonic welding machines. It can solve the problems of poor heat dissipation efficiency and discoloration of the surface of the welded workpiece, so as to reduce surface discoloration, reduce contact, and avoid surface discoloration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

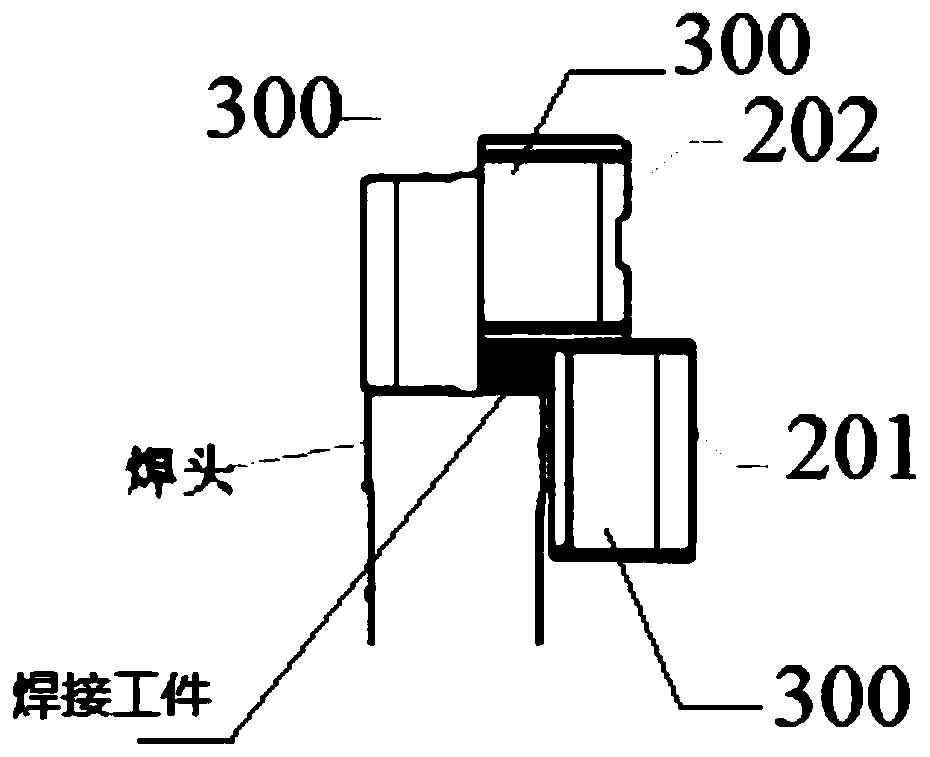

[0122] In this example, please refer to image 3 , the heat dissipation unit 300 is a metal heat dissipation block; the metal heat dissipation block is connected to the end of the wire gathering structure 100 and the wire pressing structure close to the welding workpiece, and the metal heat dissipation block is in contact with the workpiece to be welded.

[0123] It should be noted that, the heat dissipation unit 300 is set as the metal heat dissipation fast, because the thermal conductivity of the metal is high, in the welding application with large pressure, large amplitude and large cross-sectional area, using the metal heat dissipation block to contact the welding workpiece can quickly Take away the heat of the welding workpiece surface, thereby reducing the problem of discoloration of the welding workpiece surface during ultrasonic welding.

[0124] It can be understood that the metal heat dissipation block is connected to the wire gathering structure 100 and the end of t...

Embodiment 2

[0129] In this embodiment, the heat dissipating unit 300 may be a metal heat dissipating block, which is disposed on one end of the wire gathering structure 100 and the wire crimping structure close to the welding workpiece. Several through holes are opened on the metal heat dissipation block.

[0130] In the embodiment of the present invention, through holes are provided on the metal heat dissipation block, so that when the metal heat dissipation block is in close contact with the welded workpiece, heat dissipation can be effectively performed, so as to further improve the heat dissipation efficiency.

[0131] When this embodiment is used, a workpiece is positioned and welded by the wire-gathering structure 100 and the wire-pressing structure, and then the welding workpiece is pressed to start ultrasonic welding. During the ultrasonic welding process, the surface temperature of the welded workpiece increases continuously. At the same time, the heat dissipation unit 300 is al...

Embodiment 3

[0136] In this embodiment, the heat dissipation unit 300 may be a metal heat dissipation block, and a plurality of heat dissipation pipes are opened on the metal heat dissipation block, and the heat dissipation pipes pass through the pipes and the refrigerant storage mechanism (for example, the cold water storage tank) through the power source. (eg a pump). When in use, when the metal heat dissipation block is close to the welded workpiece, the staff can control to turn on the power source (such as a pump), so that the refrigerant in the refrigerant storage mechanism (such as a cold water storage tank) is driven into the heat dissipation pipe , so as to take away the heat on the metal heat sink and further improve the cooling efficiency.

[0137]In the embodiment of the present invention, a heat dissipation pipe is opened on the above-mentioned metal heat dissipation block, so that when the workpiece is close to the welded workpiece, the staff can operate the power source to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com