A process for preventing discoloration of stainless steel welding

A technology of stainless steel and craftsmanship, which is applied in the field of preventing discoloration of stainless steel welding. It can solve the problems of black appearance, discoloration and bluishness of the surface of stainless steel materials, and achieve the effect of beautiful appearance, increasing recognition and improving competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

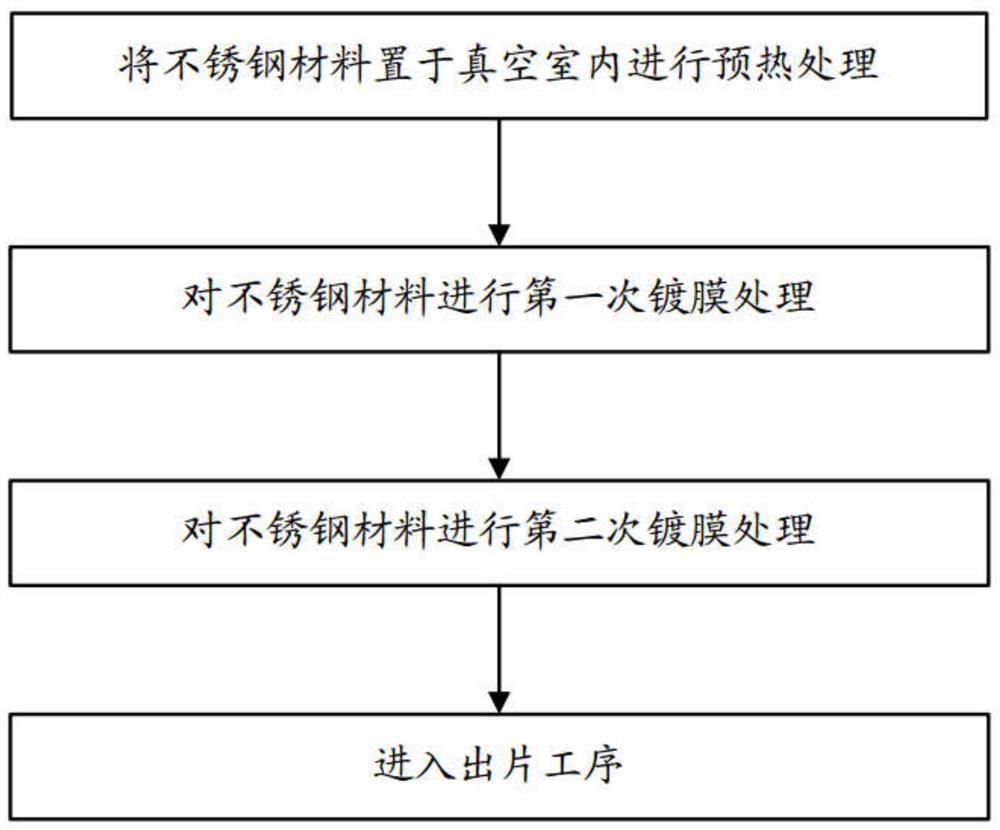

[0031] see figure 1 , a process to prevent discoloration of stainless steel welding, including:

[0032] S1. Place the stainless steel material in a vacuum chamber for preheating;

[0033] Firstly, the stainless steel material is placed in a vacuum chamber, and the problem in the vacuum chamber is raised to 150-200 degrees Celsius, which can effectively remove the moisture of the substrate and improve the adhesion between the film layer and the substrate.

[0034] Then reduce the vacuum of the vacuum chamber to 3x10 -1 -5x10 -1 Pa, coating under vacuum conditions can reduce the collision of atoms and molecules of the coating source material with gas molecules in the process of flying to the coating target, and reduce the chemical reaction between the active molecules in the gas and the coating source material (such as oxidation, etc.) , and reduce the amount of gas molecules entering the film to become impurities during the film formation process, thereby providing better f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com