Modified polyethylene and preparation method thereof

A polyethylene and modification technology, applied in the field of modified polyethylene and its preparation, can solve the problems of poor anti-ultraviolet ability, short service life, yellowing of color, etc., achieve faster dissolution speed, lower processing cost, and reduce kinetic energy The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

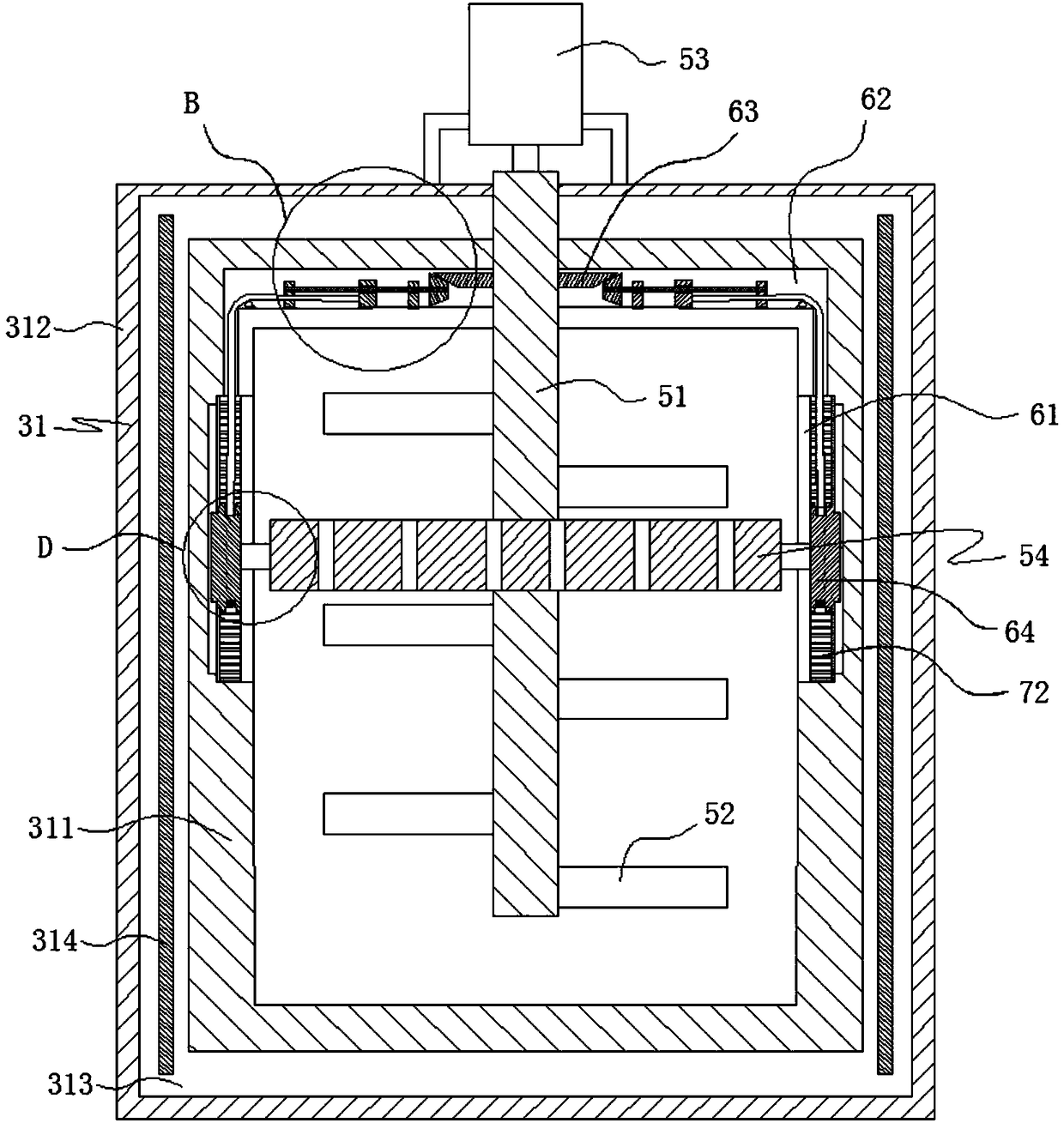

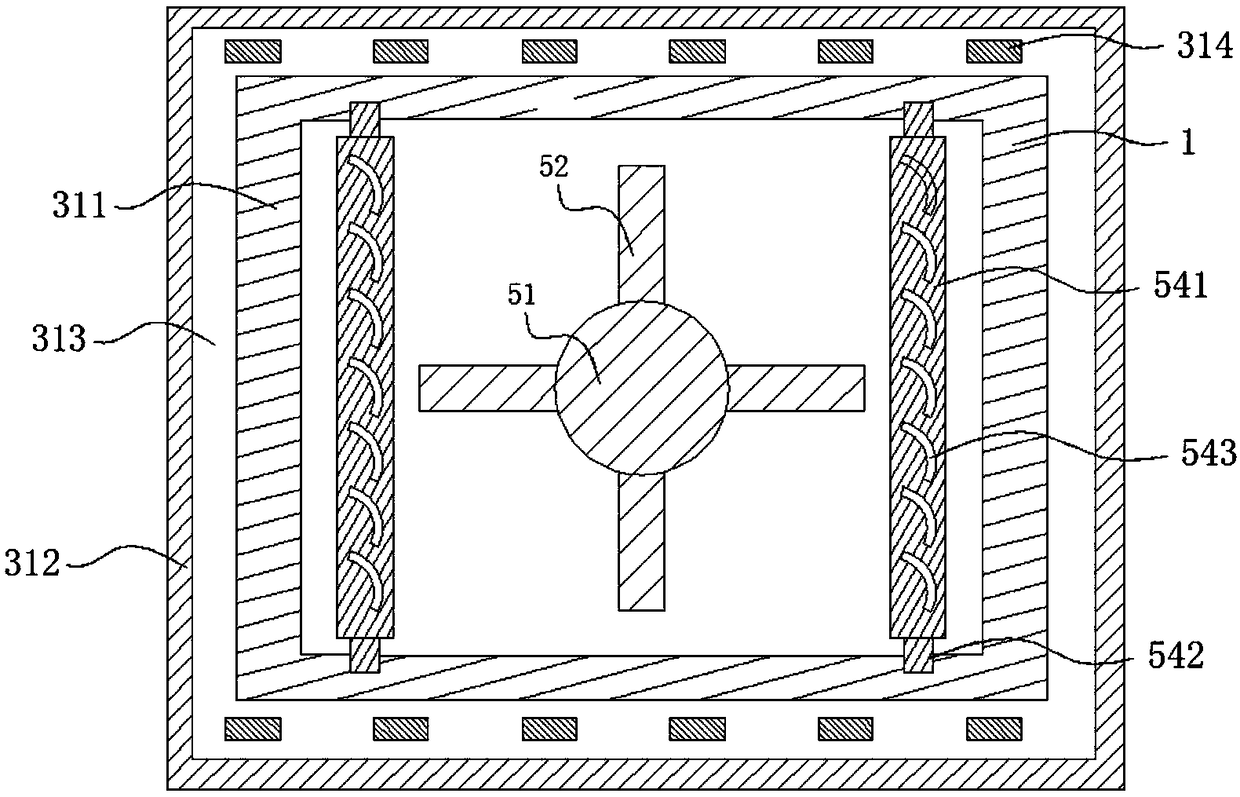

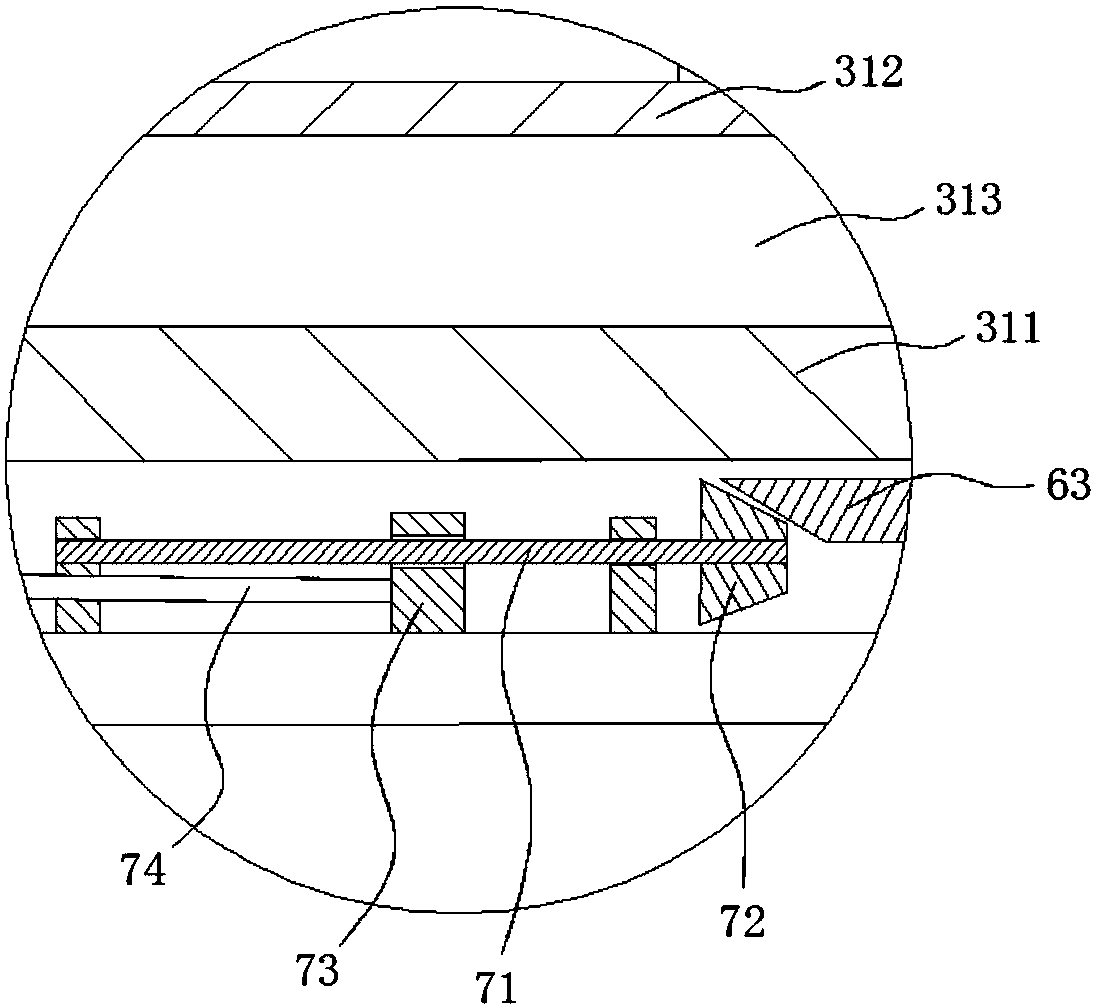

Image

Examples

Embodiment 1

[0028] A modified polyethylene, comprising the following components in parts by weight: 20 parts of polyethylene, 10 parts of nylon, 10 parts of carbon black, 5 parts of zinc oxide, 5 parts of titanium dioxide, 3 parts of mineral oil, and 2 parts of stabilizer ; Wherein, described stabilizer is the common stabilizer that obtains on the market.

[0029] A preparation method of modified polyethylene, comprising the following steps: (1) crushing 20 kg of polyethylene waste through crushing equipment to obtain fragments; (2) grinding the fragments with a grinder and passing through a 150-mesh sieve to obtain powder; ( 3) Put the powder and organic solvent into the dissolving device, mix and stir, stir at 110°C until the powder is dissolved, then continue to add polyethylene 20kg, nylon 10kg, carbon black 10kg, zinc oxide 5kg, titanium dioxide 5kg to the organic solvent, 3kg of mineral oil and 2kg of stabilizer are stirred until gelatinous to obtain a gelatinous mixture; (4) pulver...

Embodiment 2

[0036] A modified polyethylene, comprising the following components in parts by weight: 25 parts of polyethylene, 13 parts of nylon, 10 parts of carbon black, 5 parts of zinc oxide, 5 parts of titanium dioxide, 4 parts of mineral oil, and 2 parts of stabilizer ; Wherein, described stabilizer is the common stabilizer that obtains on the market.

[0037] A preparation method of modified polyethylene, comprising the following steps: (1) crushing 25kg of polyethylene waste through crushing equipment to obtain fragments; (2) grinding the fragments with a grinder and passing through a 150-mesh sieve to obtain powder; ( 3) Put the powder and organic solvent into the dissolving device, mix and stir, stir at 110°C until the powder is dissolved, then continue to add 25kg of polyethylene, 13kg of nylon, 10kg of carbon black, 5kg of zinc oxide, and 5kg of titanium dioxide into the organic solvent. 4kg of mineral oil and 2kg of stabilizer are stirred until gelatinous to obtain a gelatinous...

Embodiment 3

[0039] A modified polyethylene, comprising the following components in parts by weight: 28 parts of polyethylene, 15 parts of nylon, 12 parts of carbon black, 6 parts of zinc oxide, 6 parts of titanium dioxide, 4 parts of mineral oil, and 2 parts of stabilizer ; Wherein, described stabilizer is the common stabilizer that obtains on the market.

[0040] A preparation method of modified polyethylene, comprising the following steps: (1) taking 28kg of polyethylene waste and crushing it through crushing equipment to obtain fragments; (2) grinding the fragments with a grinder and passing through a 150-mesh sieve to obtain powder; ( 3) Put the powder and organic solvent into the dissolving device, mix and stir, stir at 110°C until the powder is dissolved, then continue to add 28kg of polyethylene, 15kg of nylon, 12kg of carbon black, 6kg of zinc oxide, and 6kg of titanium dioxide into the organic solvent. 4kg of mineral oil and 2kg of stabilizer are stirred until gelatinous to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com