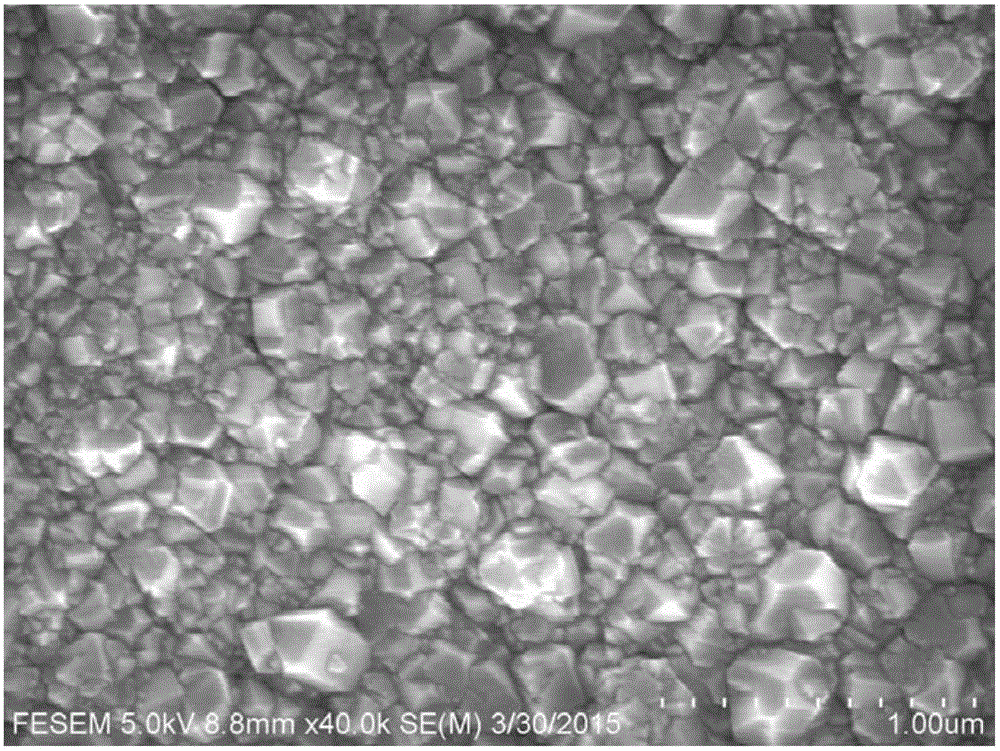

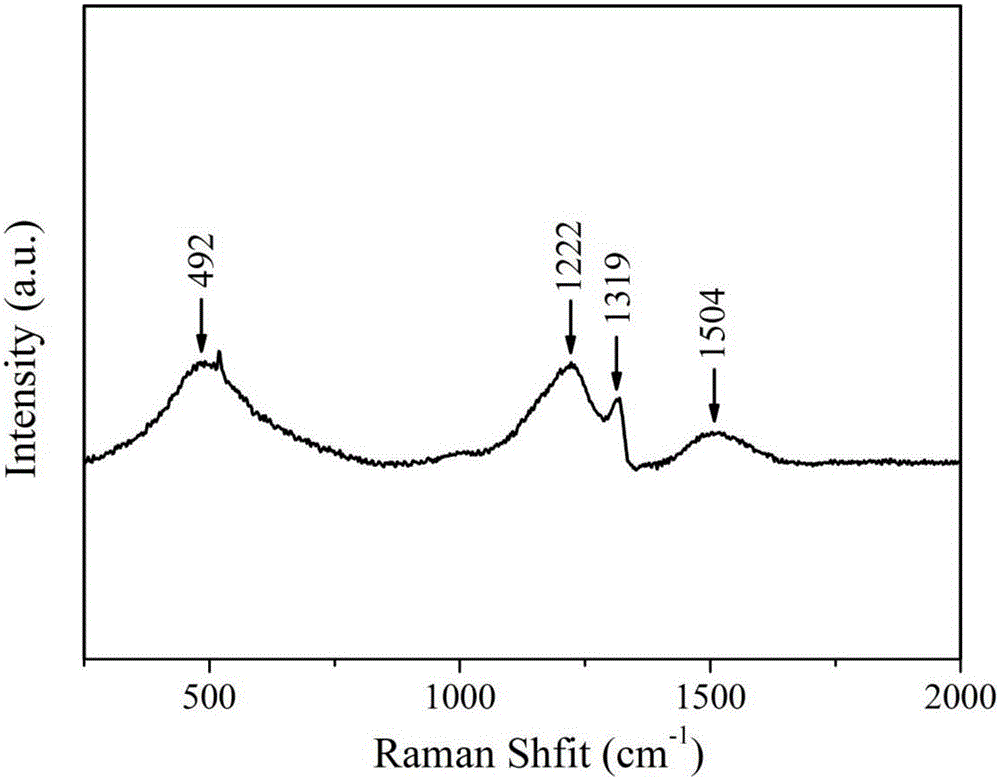

Electrochemical reduction CO2 catalyst based on boron and nitrogen co-doped nano-diamond and preparation method and application of catalyst

A nano-diamond, CO2 technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of expensive precious metals, scarce catalytic materials, poor product selectivity, etc., and achieve a wide potential window. , the effect of low background current and high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

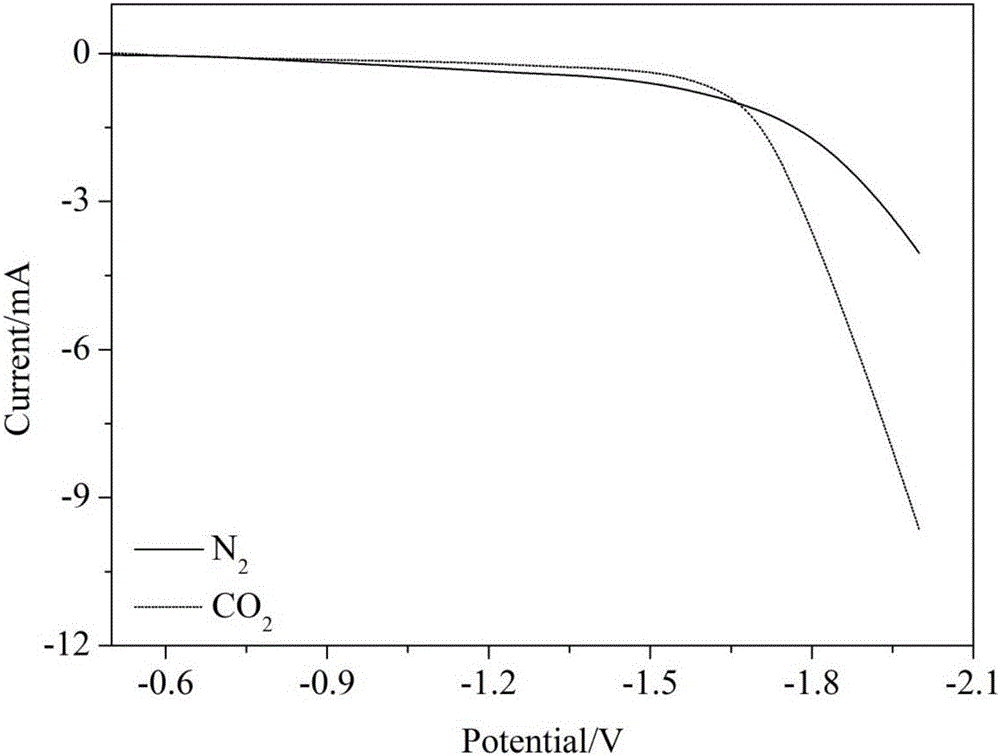

[0018] Example 1, boron and nitrogen co-doped nano-diamond electrochemical reduction of CO 2 active

[0019] A H-type double-cell reactor is used, in which the volume of the single cell is 100mL, the middle of the double cell is separated by a proton exchange membrane, the reactor is sealed, and the cathode chamber and the anode chamber are continuously fed with CO before the reaction. 2 The gas was saturated for 1h, and the gas flow rate was 20 sccm. A three-electrode working system is adopted, boron-nitrogen co-doped nano-diamond is the working electrode, the Pt electrode is the counter electrode, and the Ag / AgCl electrode is the reference electrode. The distance between the working electrode and the Pt electrode is 1.5cm, and the reference electrode is as close as possible to the working electrode. , respectively, in saturated CO 2 and N 2 0.1mol / L NaHCO 3 The linear voltammetry curve is measured in the aqueous solution, the area of the working electrode and the volum...

Embodiment 2

[0022] Example 2, boron and nitrogen co-doped nano-diamond electrochemical reduction of CO 2 stability

[0023] A H-type double-cell reactor is used, in which the single-cell volume is 100mL, and the middle of the double-cell is separated by a proton exchange membrane. The reactor is sealed, and the gas-phase product is collected by an air bag, and the liquid-phase product is detected by gas chromatography. Before the reaction, the cathode chamber and the anode chamber were continuously fed with CO 2 The gas was saturated for 1h, and CO was continuously exposed during the reaction 2 Gas, the gas flow rate is 15 sccm, the cathode chamber is magnetically stirred, and the rotation speed is constant. In the three-electrode working system, boron-nitrogen co-doped nano-diamond is used as the working electrode, the Pt electrode is used as the counter electrode, and the Ag / AgCl electrode is used as the reference electrode. The distance between the working electrode and the Pt electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com