Halogen tungsten lamp bulb having lamp bulb-contained lamp bulb structure

A bubble-in-bubble, tungsten-halogen technology, which is applied in the field of tungsten-halogen bulbs, can solve problems such as the inability to guarantee the service life of the bulb, insufficient brightness of the bulb, and easy fuse of the tungsten wire, so as to achieve the effects of increasing the service life, improving the use efficiency, and improving the brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

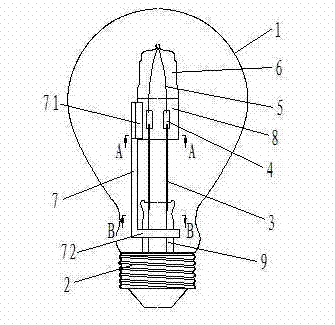

[0013] like figure 1 As shown, a tungsten-halogen bulb with a bubble-in-bubble structure includes a bulb shell 1, a lamp holder 2, the lower end of the tungsten wire lead 3 is connected to the joint of the lamp holder 2, and the upper end is passed through an aluminum-molybdenum sheet 4 and a tungsten wire 5. connect. The outside of the tungsten wire 5 is provided with a halogen bulb 6, and the inside of the halogen bulb 6 is filled with krypton gas.

[0014] like figure 1 , 2 As shown, there is also a supporting frame 7 inside the bulb 1, and the upper end of the supporting frame 7 is a clip structure 71, which clamps and fixes the outer contour of the glass body 8 that is made of the aluminum-molybdenum sheet 4 and is integrally made with the halogen bulb 6; the lower end of the supporting frame 7 The clamp structure 72 clamps and fixes the outer contour of the glass body 9 of the tungsten wire lead 3 . Through the clamping of the support frame 7, structures such as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com