Three-layer stereo power encapsulation method and structure

A packaging method and power technology, which is applied in the manufacture of semiconductor devices, electric solid devices, semiconductor/solid devices, etc., can solve the problems of power integration and packaging of IPM products, and achieve the effects of low cost, simplified production process, and easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will be further described in more detail in conjunction with the accompanying drawings and specific embodiments.

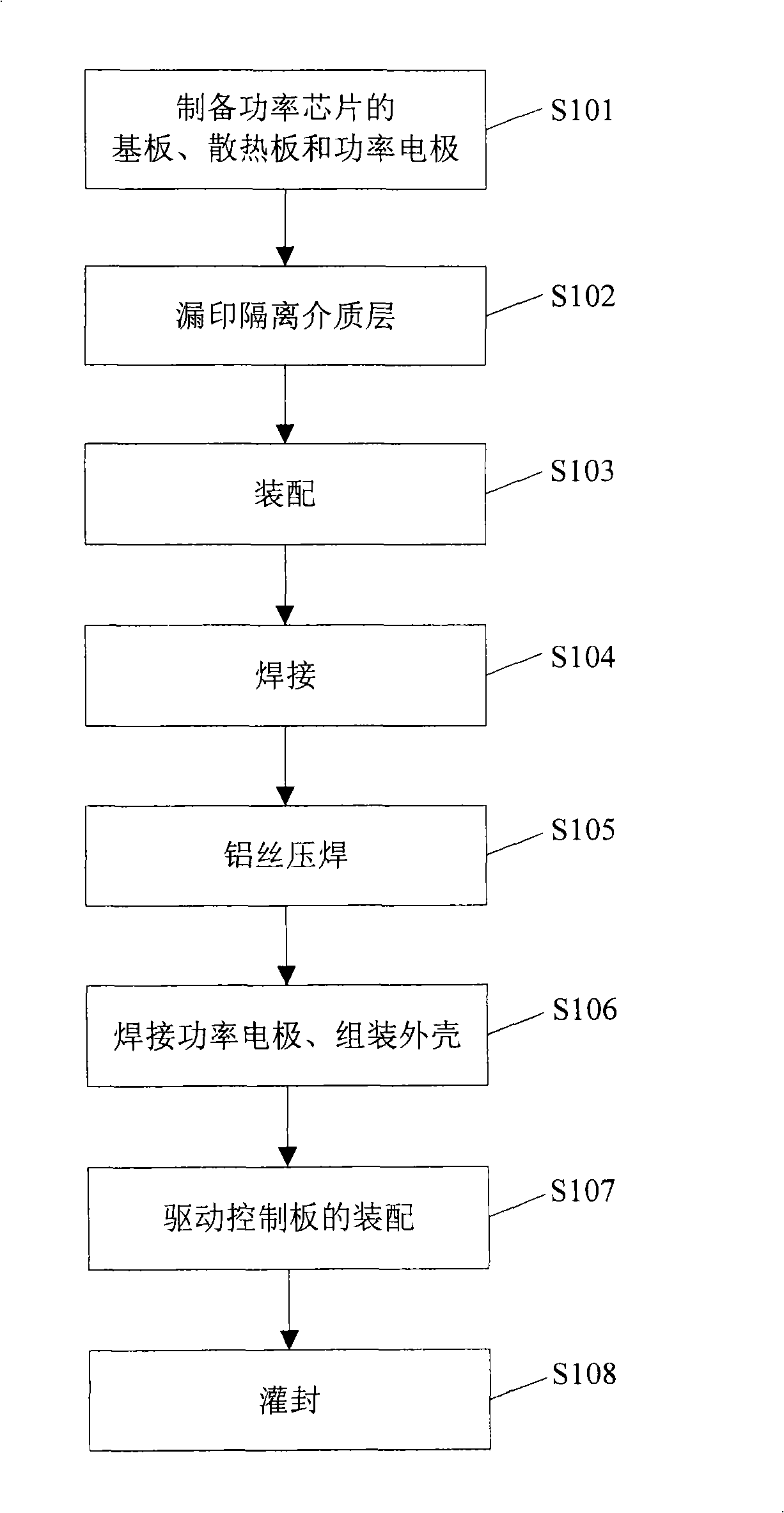

[0051] Such as figure 1Shown is the process flow diagram of the three-layer three-dimensional packaging method of the present invention. The method tightly installs the power board part, the drive control board part, and the power electrode part in a package from bottom to top, and the method includes the following steps:

[0052] Step S101, preparing the substrate of the power chip, the cooling plate and the power electrode;

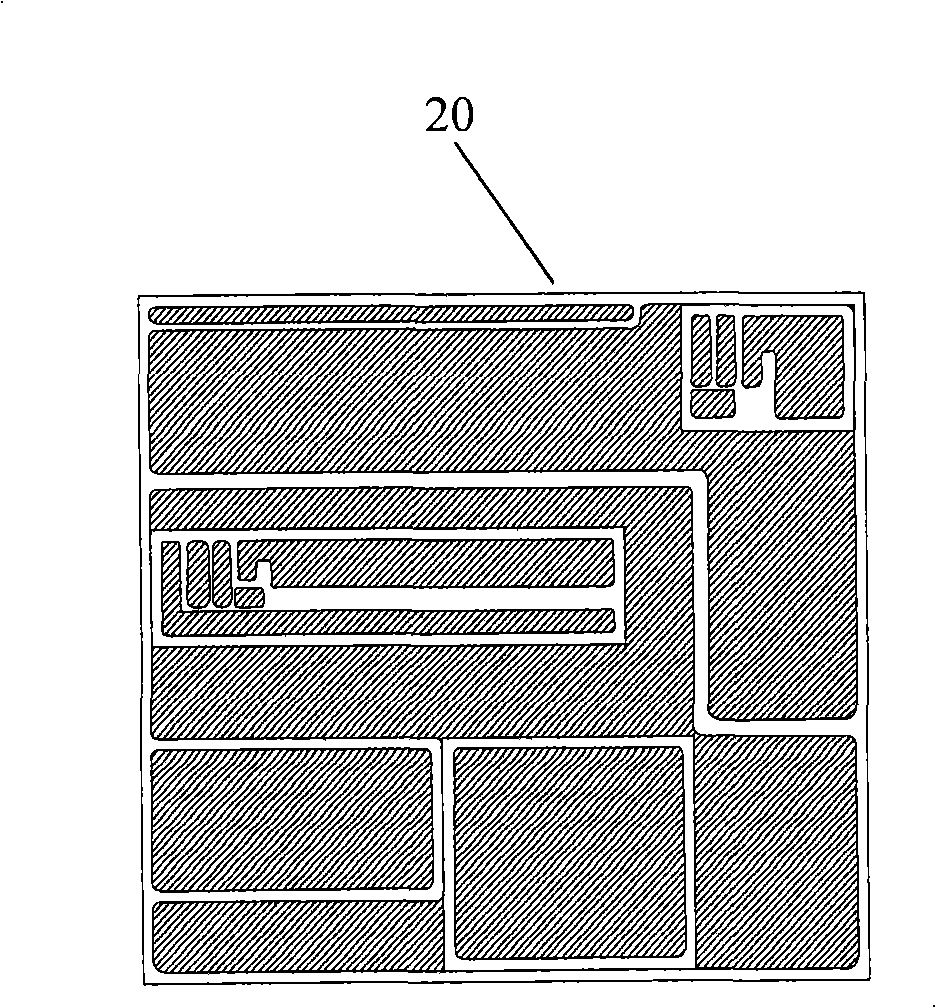

[0053] In this step, design and process the copper heat sink and power electrodes according to the required size; design and process the ceramic copper clad board (DCB) as the mounting substrate of the power chip according to the layout requirements of the power device, such as Figure 2a , Figure 2b , Figure 2c , Figure 6, wherein 10 is a copper heat sink, 20 is a ceramic copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com