Testing experimental platform for performing disruptive discharge on insulation sample under low-temperature vacuum environment

A technology of breakdown discharge and low temperature vacuum, applied in the direction of testing dielectric strength, components of electrical measuring instruments, measuring electricity, etc., can solve insulation breakdown damage, damage to large-scale superconducting systems of electrical components of aerospace probes, cracking, etc. problem, to achieve the effect of convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

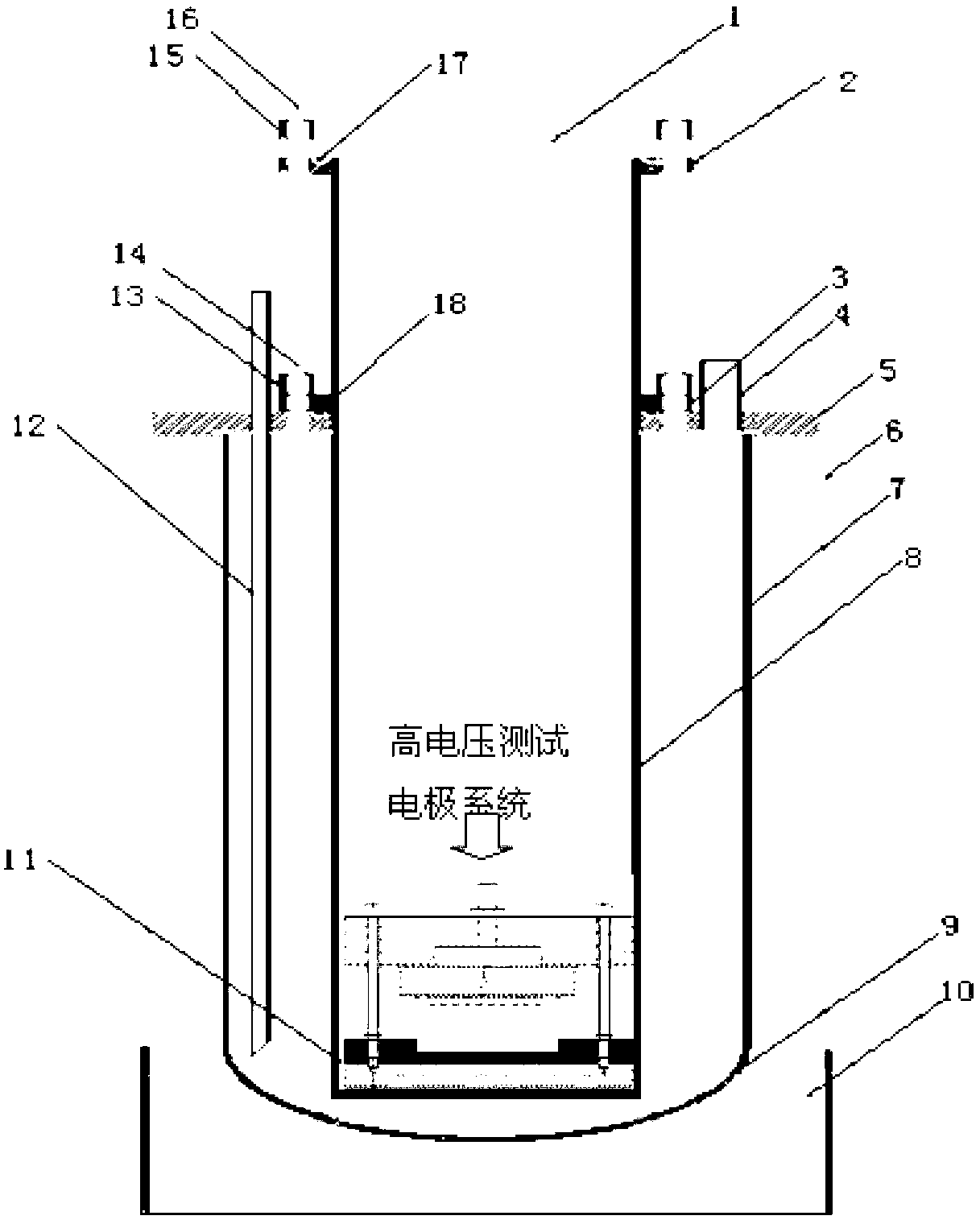

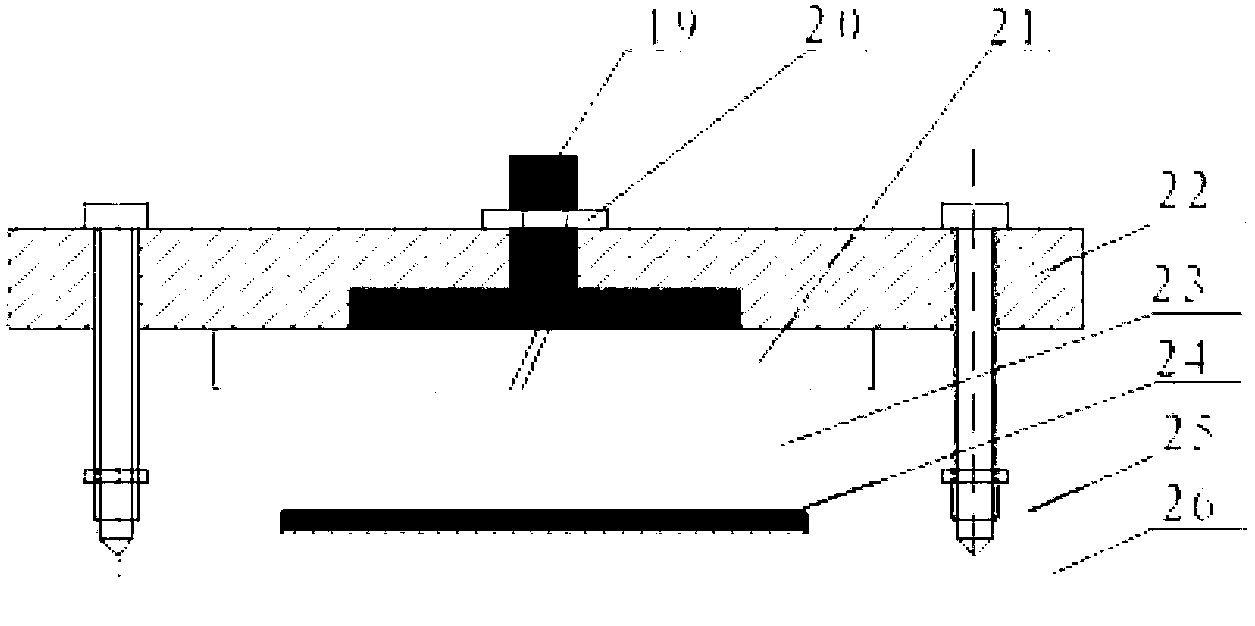

[0029] See attached Figure 1-4 , used for the breakdown discharge test experiment platform of insulation samples in low-temperature vacuum environment, mainly including three-layer experimental Dewar container and high-voltage test electrode system. The three-layer experimental Dewar container is a vacuum test container 8 from the inside to the outside. , liquid helium (or liquid nitrogen) cooling cylinder 7 and vacuum insulation outer cylinder 6, vacuum test container 8 is higher than liquid helium (or liquid nitrogen) cooling cylinder 7 and vacuum insulation outer cylinder 6 along the axial direction, vacuum test container 8, liquid The bottom of the helium (or liquid nitrogen) cooling cylinder 7 and the vacuum insulation outer cylinder 6 respectively have a matching sealing head 11, 9, 10, and the top of the vacuum test container 8 is provided with a sealing upper flange used in conjunction with each other 1 and the lower flange 2, a sealing flange 3 and 5 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com