Vacuum argon-oxygen refining equipment, method for smelting low-carbon and ultra-low-carbon stainless steel and for smelting low-carbon ferrochrome and micro-carbon ferrochrome by applying same

An argon-oxygen refining and vacuum technology, which is applied in the fields of metallurgy and steelmaking, can solve the problems of increasing smelting cost and production loss, occupying a large area of the smelting furnace, and consuming smelting time, so as to save converter time and shorten the smelting cycle. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

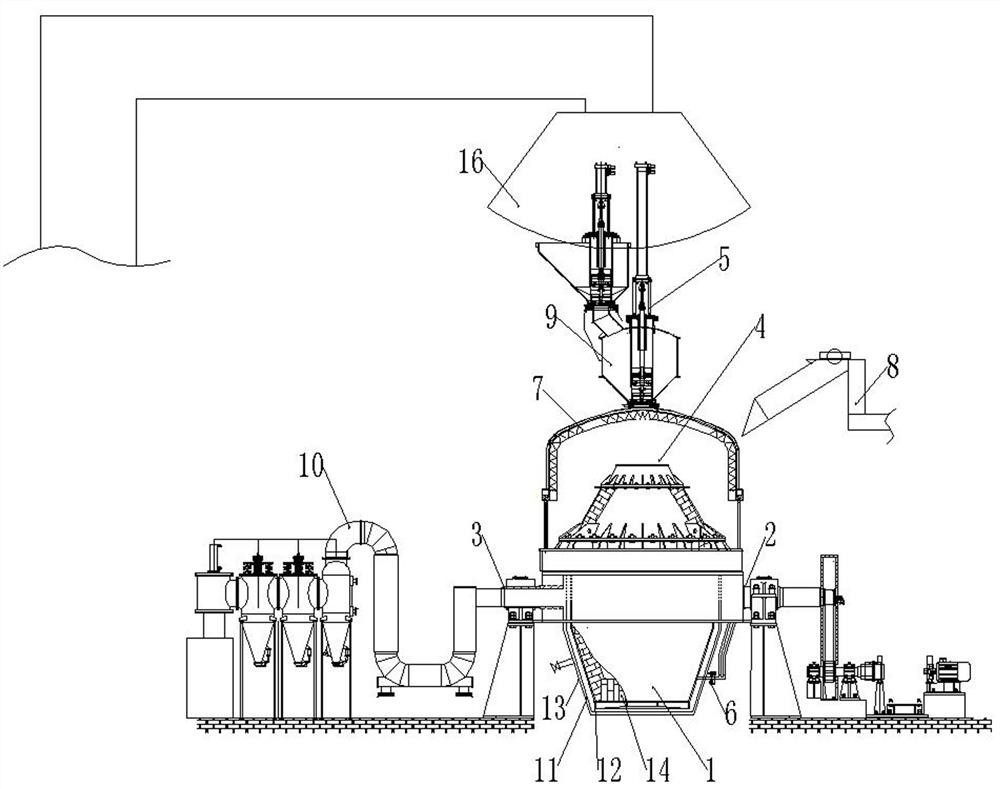

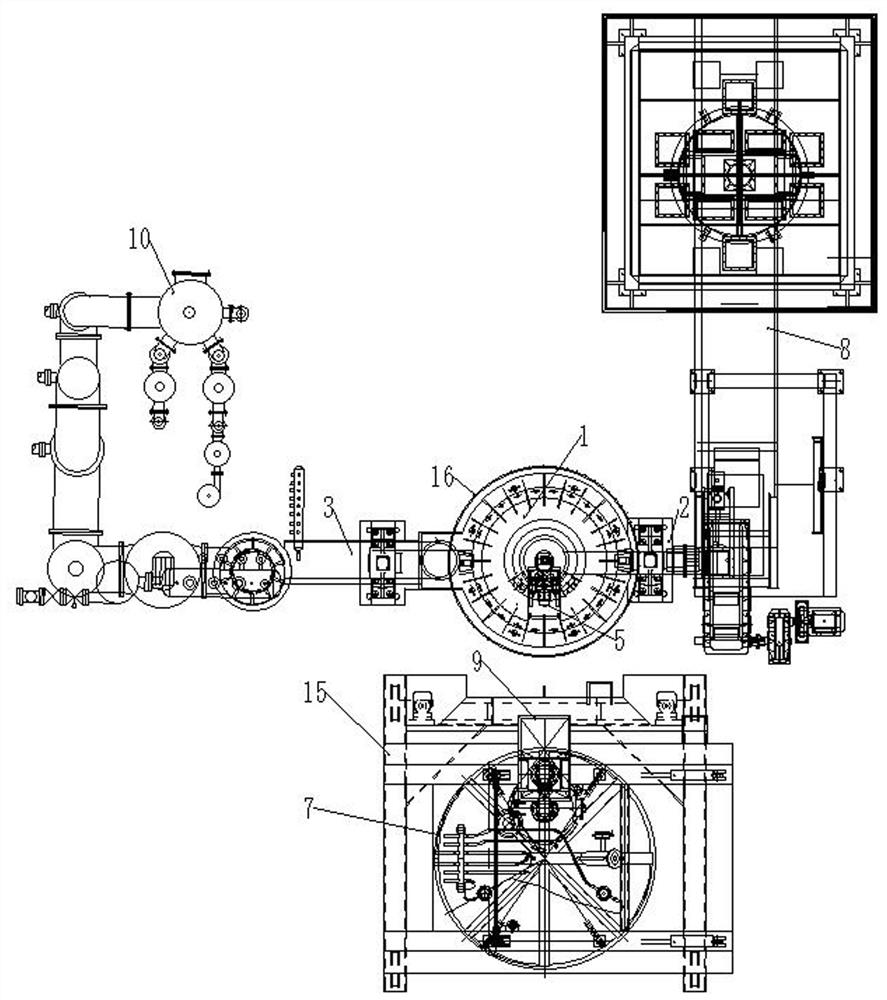

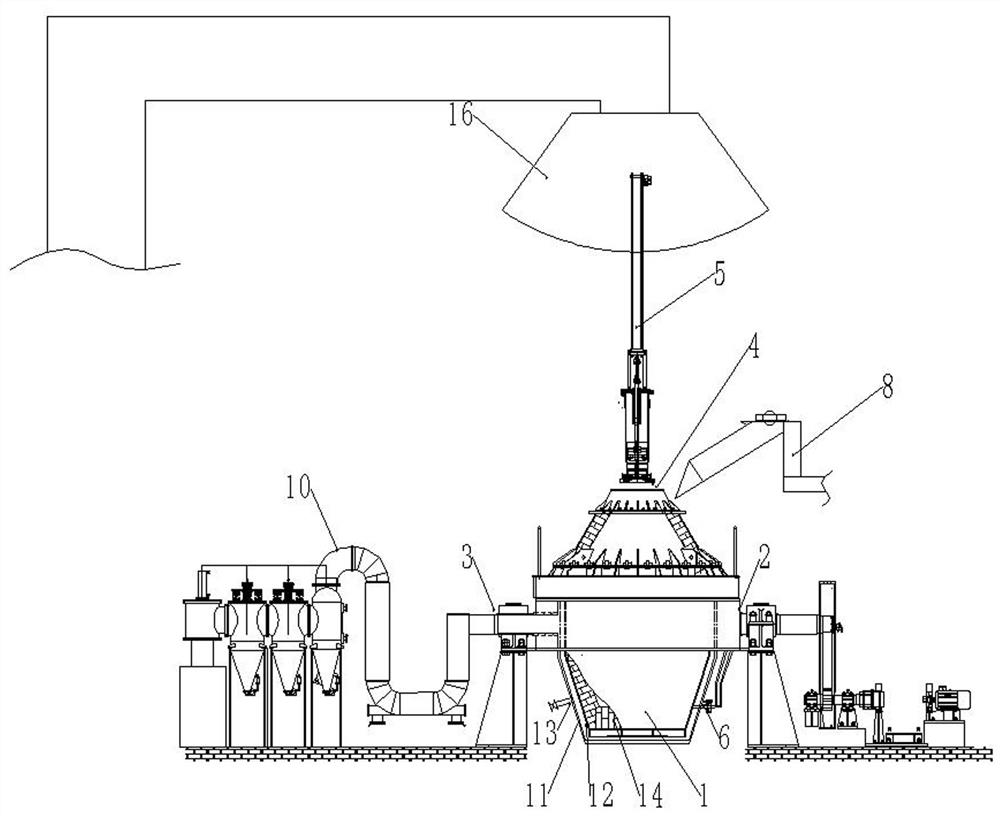

[0040] figure 1 It is a schematic structural diagram of the vacuum argon-oxygen refining equipment provided in Embodiment 1 of the present invention; figure 2 It is a top view of the vacuum argon-oxygen refining equipment provided in Embodiment 1 of the present invention; image 3 It is a structural schematic diagram of the vacuum argon-oxygen refining equipment of the present invention during the normal pressure smelting process; Figure 4 It is a structural schematic diagram of the vacuum argon-oxygen refining equipment of the present invention during the vacuum smelting process; as Figure 1 to Figure 4As shown, the vacuum argon-oxygen refining equipment includes: a furnace body 1 and a support ring sleeved on the furnace body 1, and the two sides of the support ring are symmetrically provided with a driving end trunnion 2 and a driven end trunnion 3; The furnace body 1 is provided with: a normal pressure feeding port 4, a top blowing gun 5, a bottom blowing gun 6 and a ...

Embodiment 2

[0062] On the basis of Embodiment 1, the vacuum argon-oxygen refining equipment, the furnace body 1 includes: a furnace shell 13 and an inner cavity; the inner cavity is a double-layer structure, including a sealed outer layer 11 and a gas-permeable inner layer 12, the Refractory bricks 14 are arranged on the inner wall of the air-permeable inner layer 12 .

[0063] The inner cavity in this embodiment is designed with a double-layer structure, the inner layer is used for ventilation, and the outer layer is used for sealing, which can effectively ensure the vacuum degree inside the furnace body during the vacuum smelting process.

Embodiment 3

[0065] On the basis of Embodiment 1, vacuum argon-oxygen refining equipment, a water-cooling pipe is provided between the furnace shell 13 and the sealed outer layer 11, and a water inlet and a water outlet are provided on the furnace shell 13, and the water-cooling pipes are respectively It is connected with the water inlet and the water outlet, and the water-cooling pipeline is connected with the external water-cooling cycle control system through the water inlet; the water-cooling pipeline can be a serpentine tube structure, a tube structure or other structures.

[0066] The water-cooled pipeline in this embodiment can keep the furnace body 1 under the protection of the water-cooled pipeline all the time during smelting, prevent the furnace body from being overheated and deformed, and affect the vacuum degree in the furnace, and can also effectively prolong the service life of the furnace body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com