Liquid crystal composite film with writing display function and preparation method thereof

A composite film, display function technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of contact short circuit, increased driving voltage, and high driving voltage, so as to improve the yield and life, reduce the amount of liquid crystal usage, use The effect of a wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

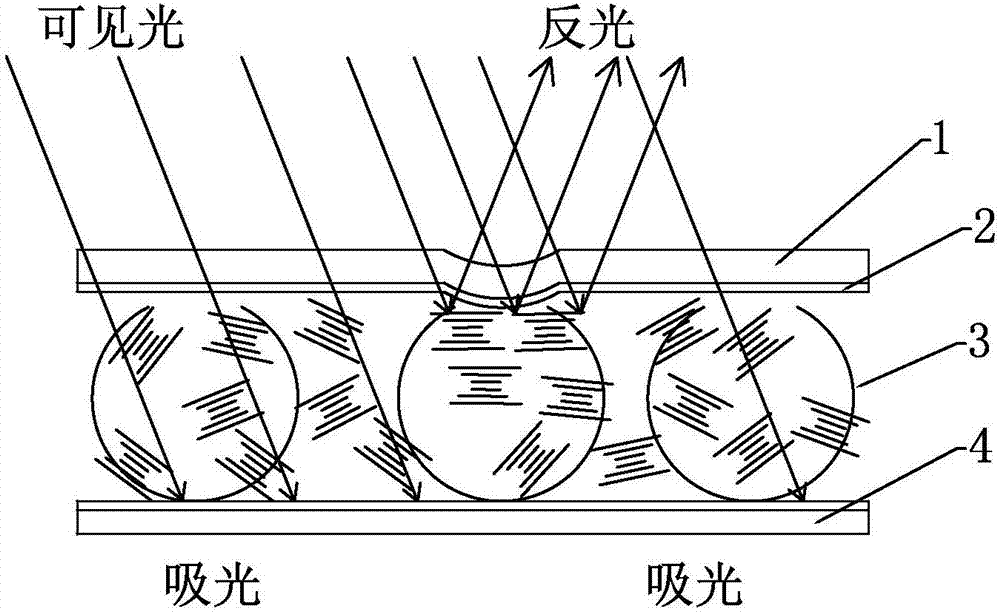

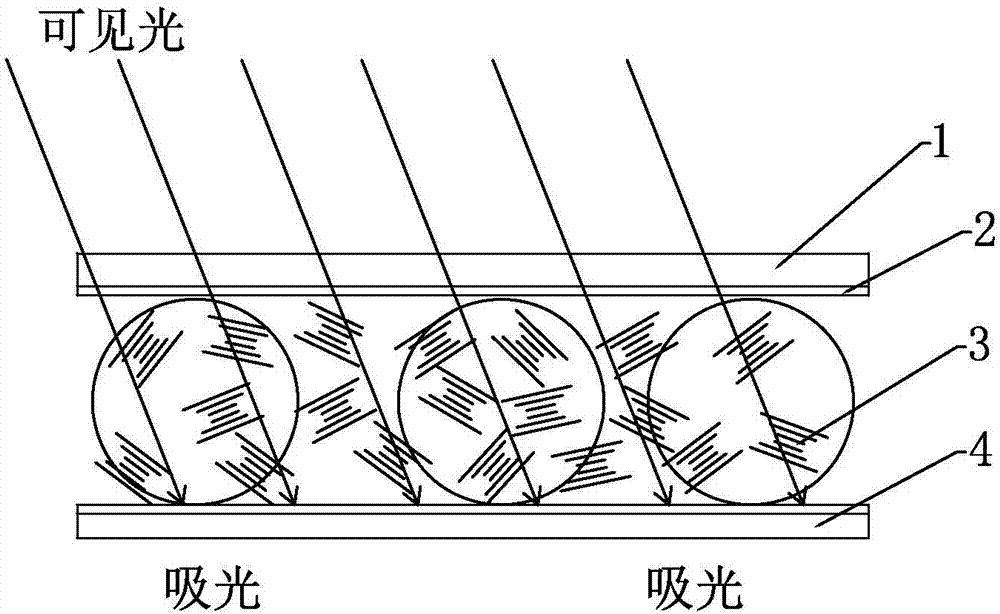

[0054] Such as Figure 1-Figure 2 As shown, the liquid crystal composite film with writing and display functions in this embodiment includes, from top to bottom: a PET transparent film 1 coated with an ITO layer on the lower surface, a PVA insulating alignment layer 2, a liquid crystal / polymer / spacer microsphere composite layer 3 and PET black film 4 coated with an ITO layer on the upper surface.

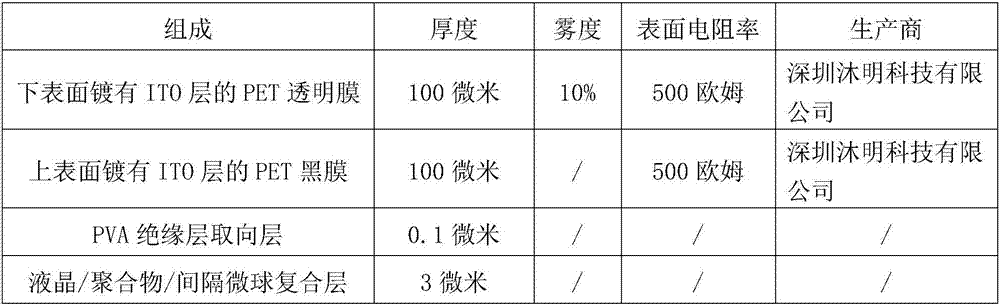

[0055] The parameters of each layer structure of the liquid crystal composite film with writing display function are as follows:

[0056]

[0057] In this liquid crystal composite film with writing display function, the composition of the liquid crystal polymer layer is as follows (in 100 kilograms, the same below):

[0058]

[0059] The particle size of the polystyrene microspheres is 3 microns.

[0060] The preparation method of the liquid crystal composite film with writing display function, comprises the following steps:

[0061] (1) Prepare a PET transparent film that ...

Embodiment 2

[0076] Such as Figure 1-Figure 2 As shown, the liquid crystal composite film with writing and display functions in this embodiment includes, from top to bottom: a PET transparent film 1 coated with an ITO layer on the lower surface, a PVA insulating alignment layer 2, a liquid crystal / polymer / spacer microsphere composite layer 3 and PET black film 4 coated with an ITO layer on the upper surface.

[0077] The parameters of each layer structure of the liquid crystal composite film with writing display function are as follows:

[0078]

[0079] In this liquid crystal composite film with writing display function, the composition of the liquid crystal polymer layer is as follows (in 100 kilograms, the same below):

[0080]

[0081] The particle size of the polystyrene microspheres is 5 microns.

[0082] The preparation method of the liquid crystal composite film with writing display function, comprises the following steps:

[0083] (1) Prepare a PET transparent film that ...

Embodiment 3

[0098] Such as Figure 1-Figure 2 As shown, the liquid crystal composite film with writing and display functions in this embodiment includes, from top to bottom: a PET transparent film 1 coated with an ITO layer on the lower surface, a PVA insulating alignment layer 2, a liquid crystal / polymer / spacer microsphere composite layer 3 and PET black film 4 coated with an ITO layer on the upper surface.

[0099] The parameters of each layer structure of the liquid crystal composite film with writing display function are as follows:

[0100]

[0101] In this liquid crystal composite film with writing display function, the composition of the liquid crystal polymer layer is as follows (in 100 kilograms, the same below):

[0102]

[0103] The particle size of the polystyrene microspheres is 15 microns.

[0104] The preparation method of the liquid crystal composite film with writing display function, comprises the following steps:

[0105] (1) Prepare a PET transparent film that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com