Automatic withstand voltage detecting and automatic sorting device of safety equipment

A safety tool and automatic detection technology, used in sorting, testing dielectric strength and other directions, can solve the problems of small one-time withstand voltage test, complicated and laborious installation of suspension insulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

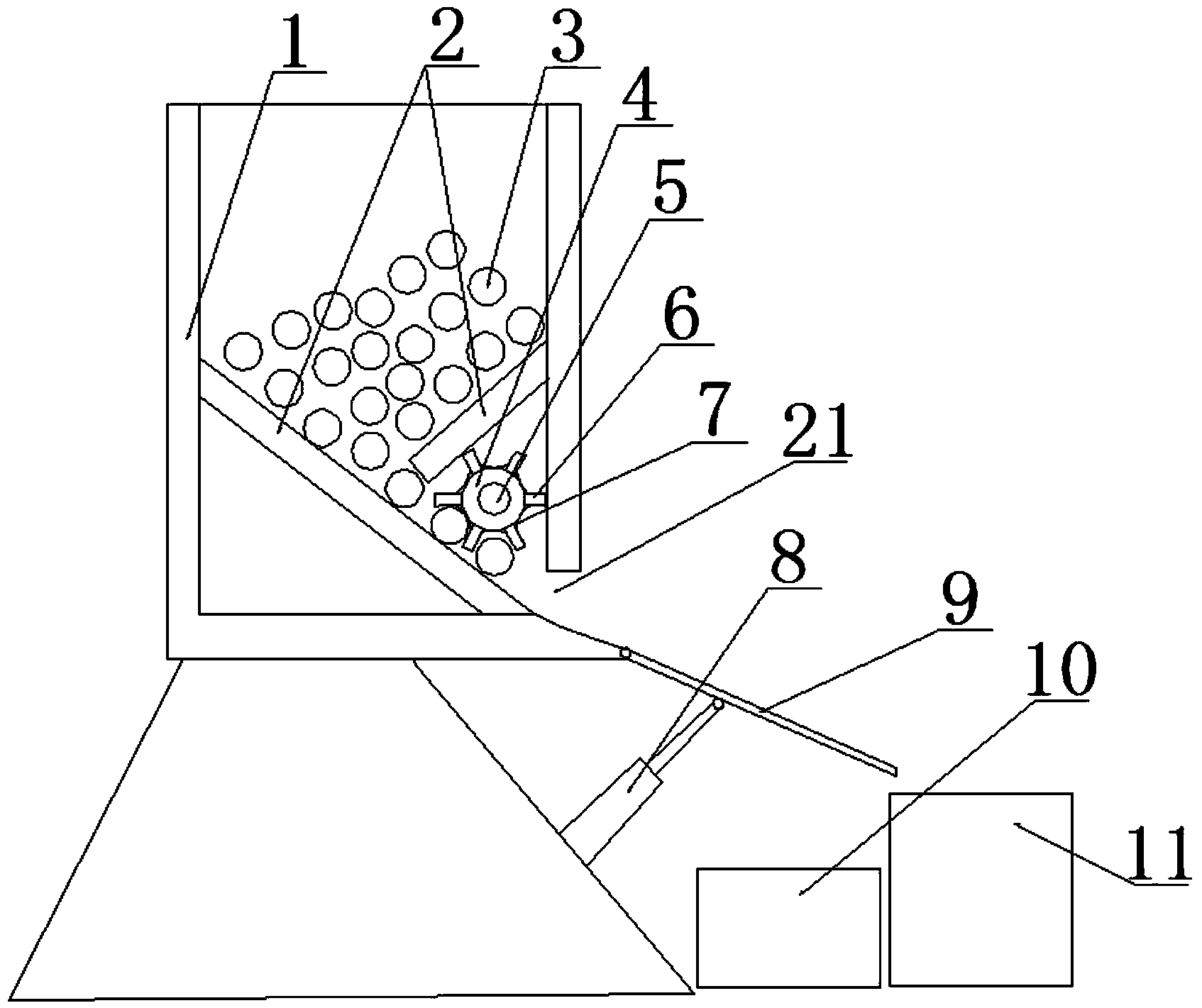

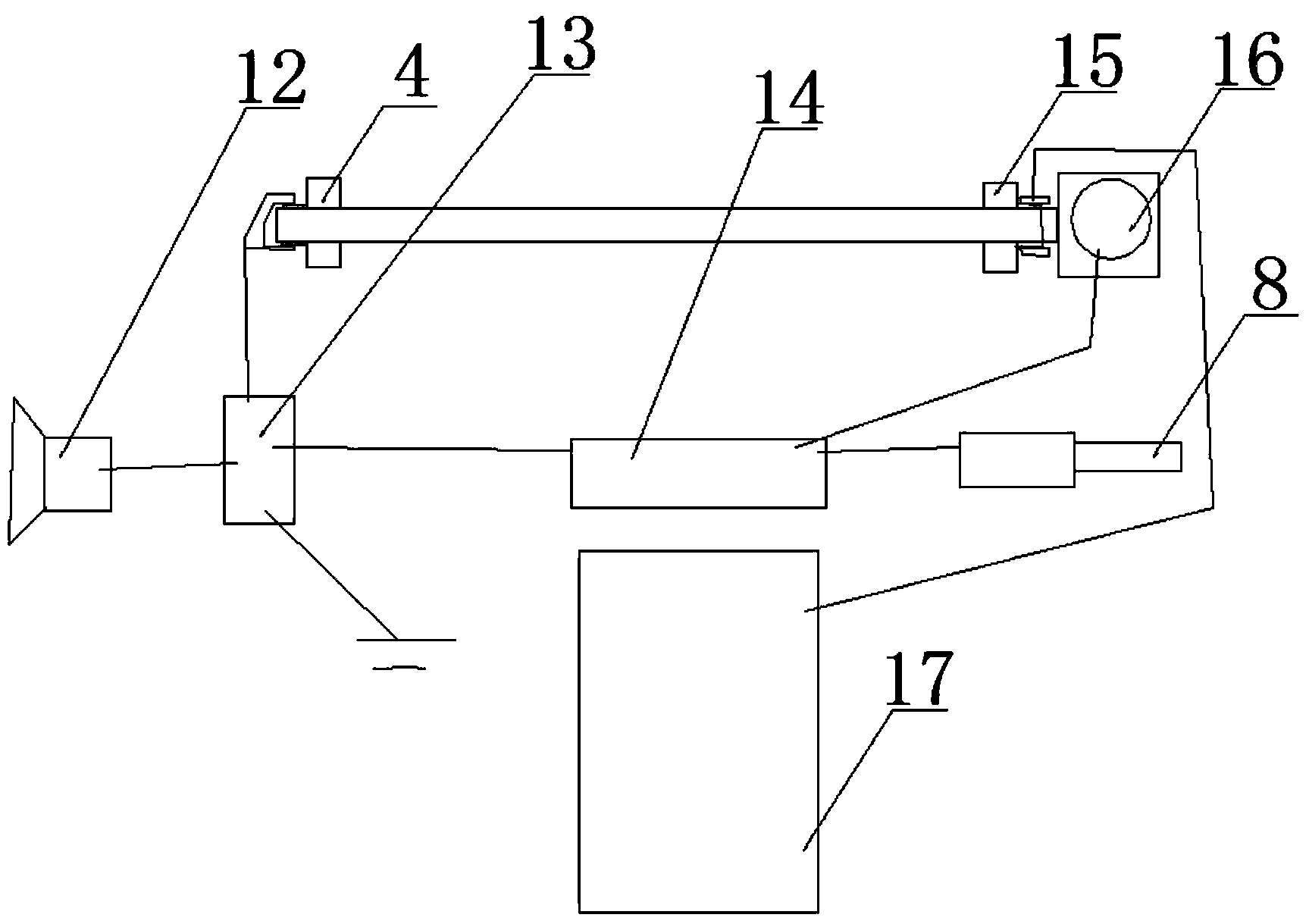

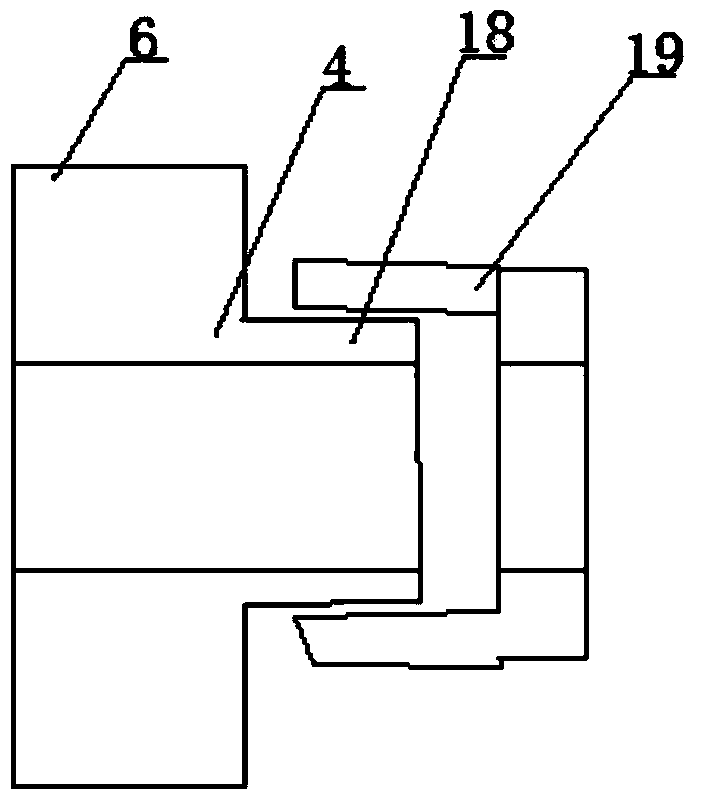

[0013] Such as figure 1 , 2 As shown in , 3 and 4, a pressure-resistant automatic detection and automatic classification device for safety tools includes a box body 1, and a flow guide 2 is arranged in the box body 1, and the flow guide 2 is in an inverted figure-eight shape, and the backflow effect is good; the box body 1, an appliance outlet 21 is arranged below the appliance outlet 21, and a rotating shaft 5 is arranged at the appliance outlet 21. The rotating shaft 5 is connected to the reduction motor 16 arranged on the outside of the box body 1. One end of the rotating shaft 5 is set with a grounding push roller 4, and the other end is set with a high-voltage The dial 15, the ground dial 4 and the high-voltage dial 15 are provided with a dial 6, the ground dial 4 and the high-voltage dial 15 are all provided with elastic conductive members 7, the box 1, the flow guide 2. Both the rotating shaft 5 and the dial 6 are made of insulating material, and the dials 6 are evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com