LED flip chip

A technology of flip-chip and lead electrodes, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as LED chip short circuit, cracked metal bumps, and affecting the reliability of LED chip work, so as to increase the welding area, The effect of reducing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

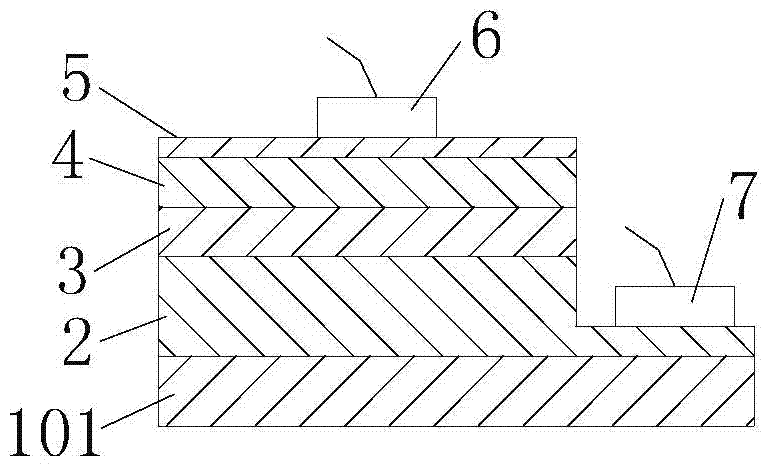

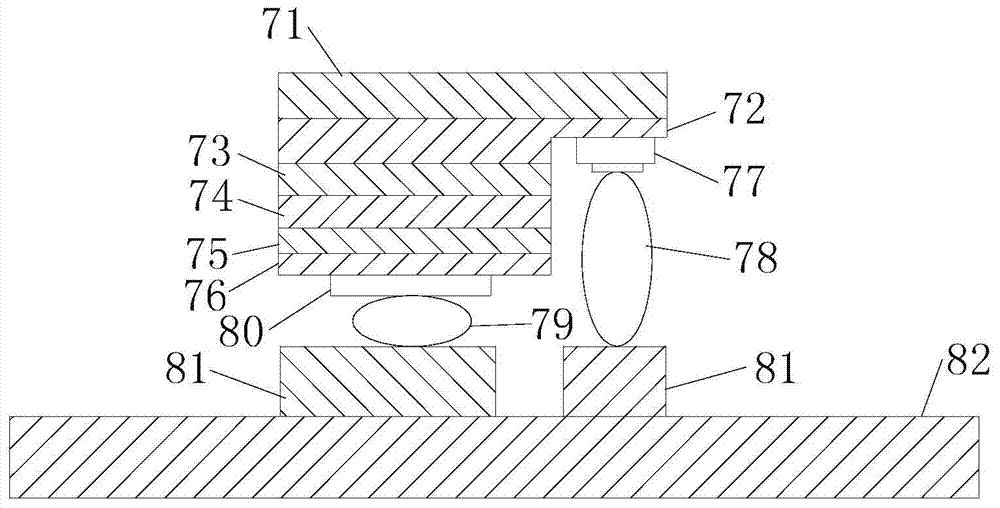

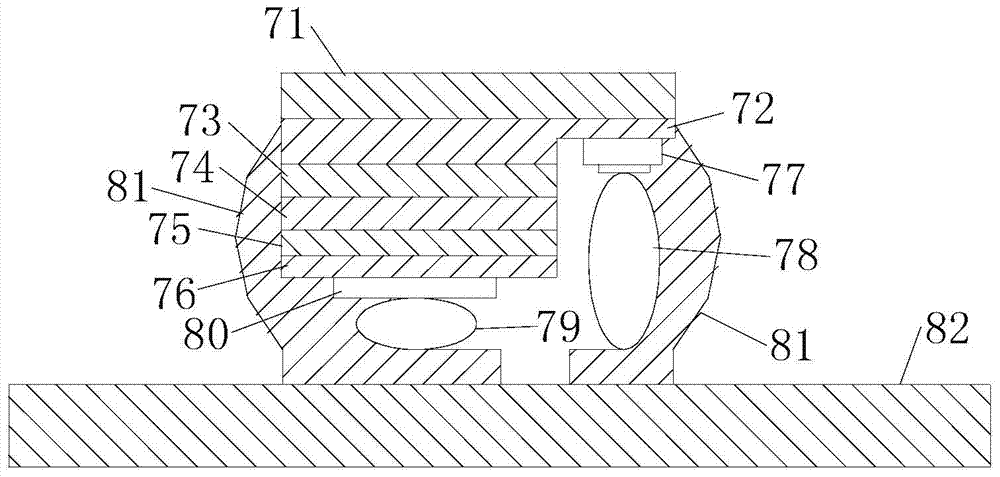

[0028] see Figure 4 and Figure 5 , LED flip-chip, including a sapphire substrate 1, sequentially arranged on the sapphire substrate 1 from bottom to top, and sequentially provided with an N-type layer 11, a light-emitting layer 12, a P-type layer 13, a reflective layer 15, The first insulating layer 16 . The first insulating layer 16 is provided with an N lead electrode 17 and a P lead electrode 18, and the N lead electrode 17 extends from the P-type layer 13 to the hole 14 of the N-type layer 11 along the depth (refer to Figure 9 ) is electrically connected to the N-type layer 11, and the P lead electrode 18 is electrically connected to the reflective layer 15. The N lead electrode 17 and the P lead electrode 18 are provided with a second insulating layer 22 , and the second insulating layer 22 is provided with a through hole 28 . The N pad layer 26 and the P pad layer 27 are respectively disposed on the second insulating layer 22 , and respectively contact the N lead e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com