Motor iron core automatic adhesive lamination high-speed stamping progressive die

A high-speed stamping and automatic technology, applied in the direction of forming tools, manufacturing tools, mechanical equipment, etc., can solve the problems of low production efficiency, reduced motor performance, motor performance and dimensional deformation, so as to improve work efficiency, reduce labor costs, overlap high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

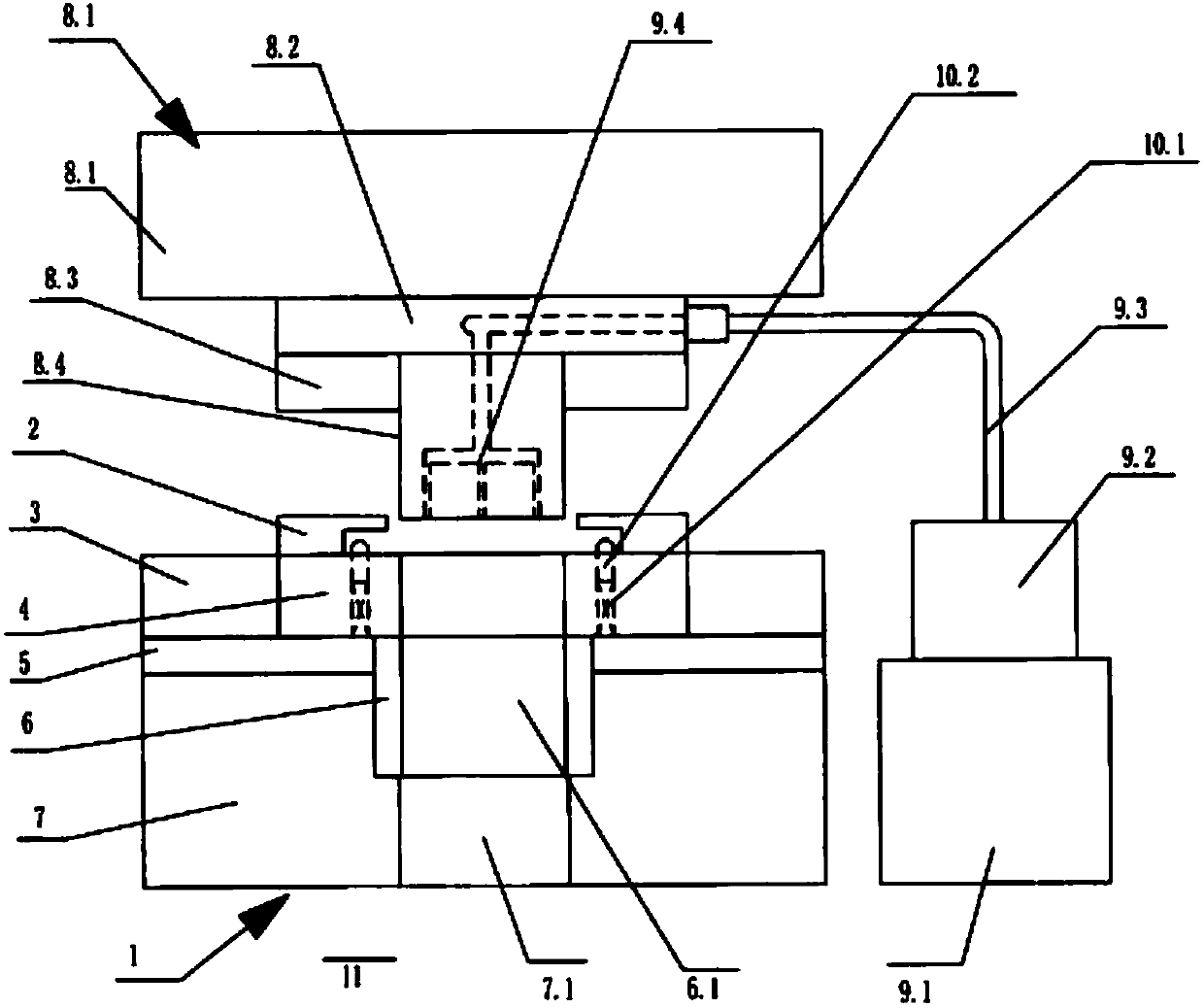

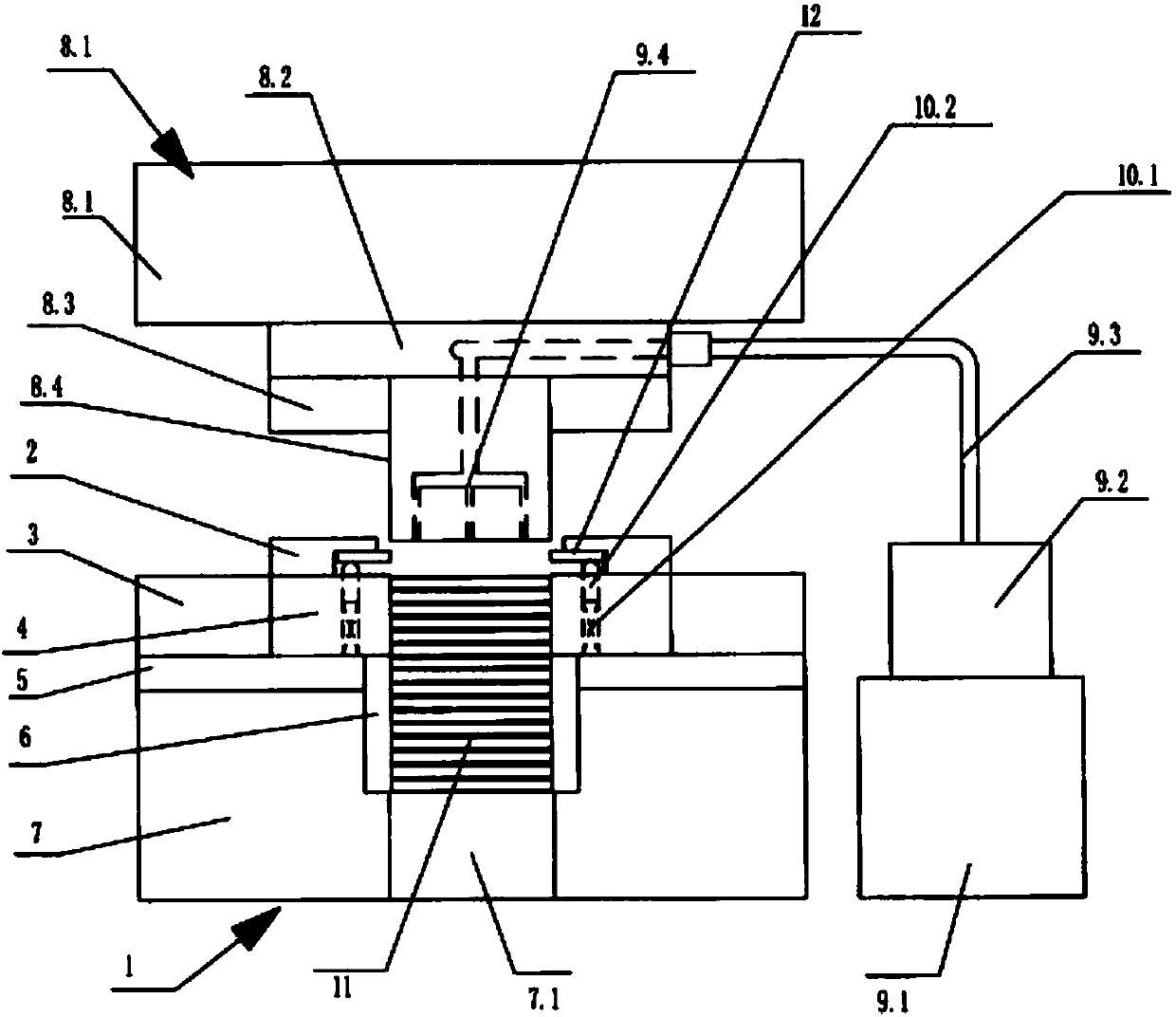

[0020] refer to figure 1 , figure 2 As shown, the motor iron core automatic viscose laminated high-speed stamping progressive die includes an upper die 8, a lower die 1, and a material guide plate 2. The upper die 8 includes an upper die base 8.1, an upper backing plate 8.2, and a punch Backing plate 8.3 and blanking punch 8.4, the lower mold 1 includes a blanking die 3, a die template 4, a die backing plate 5, a locking ring 6, a lower die seat 7, and a blanking die from top to bottom. 3 is installed in the concave template 4, the locking ring 6 is located under the blanking die 3, and the locking ring 6 is provided with locking holes 6.1 in the axial direction to ensure the verticality and parallelism between the punching pieces 11, and the blanking die 3 is opposite to the locking hole 6.1, the inner diameter of the locking ring 6 is smaller than the inner diameter of the blanking die 3, the locking ring 6 is placed in the lower mold base 7, and the product outlet 7.1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com