Nonferrous mine waste rock storage yard ecological environmental management method

A non-ferrous metal, ecological environment technology, applied in the fields of land preparation methods, applications, agricultural machinery and implements, etc., can solve the problems of inability to mix fillers and water, migration of toxic substances, easy oxidation, weathering, etc., to achieve good greening effect and basic improvement , the effect of structural safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with each accompanying drawing, the present invention is described in detail.

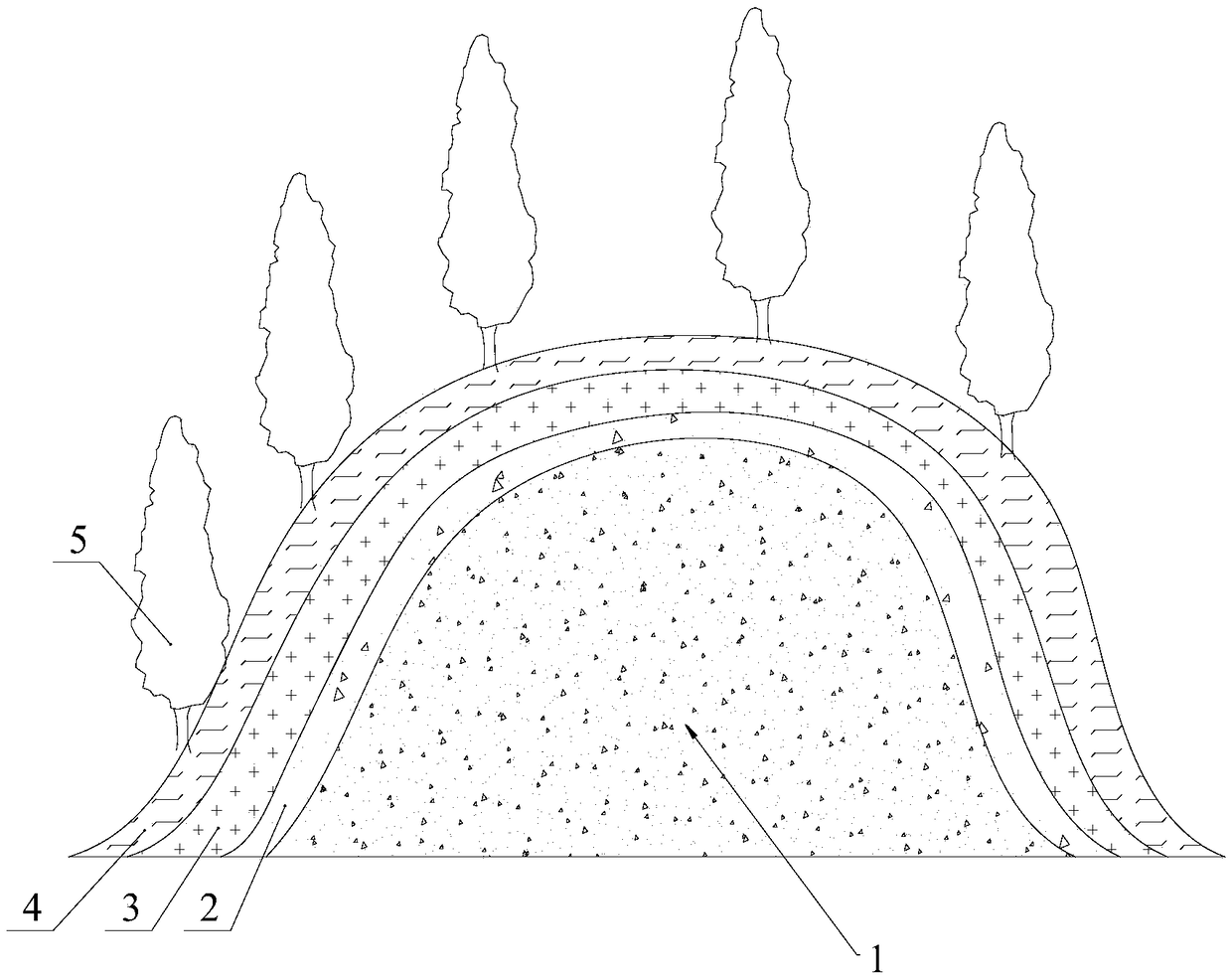

[0036] Such as figure 1 Shown, a kind of non-ferrous metal mine waste rock yard ecological environment management method, comprises the following steps:

[0037] (1) Spray the slurry-like neutralizing and improving material onto the outer surface of the waste rock yard 1 through a mud spraying machine to form a neutralizing and improving layer 2;

[0038] (2) Spray the slurry-like buffering and insulating material onto the outer surface of the neutralization improvement layer 2 through a mud spraying machine to form a buffering and insulating layer 3;

[0039] (3) The slurry-like vegetation restoration material is sprayed onto the outer surface of the buffer isolation layer to form the vegetation restoration layer 4 by means of a mud spraying machine.

[0040] This method is a wet spraying method, using a slurry sprayer to spray high-concentration mixed materials onto ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com