Patents

Literature

31results about How to "Fully embedded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

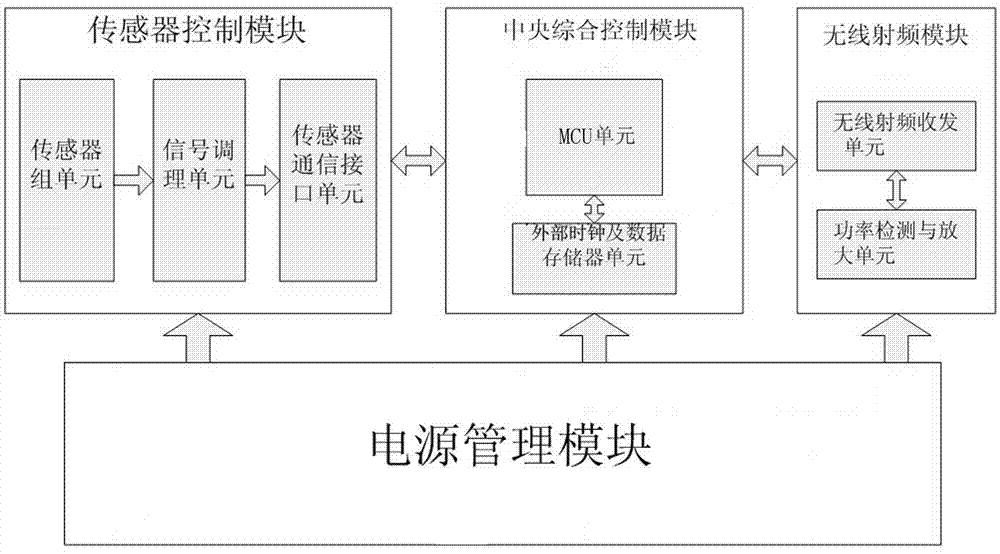

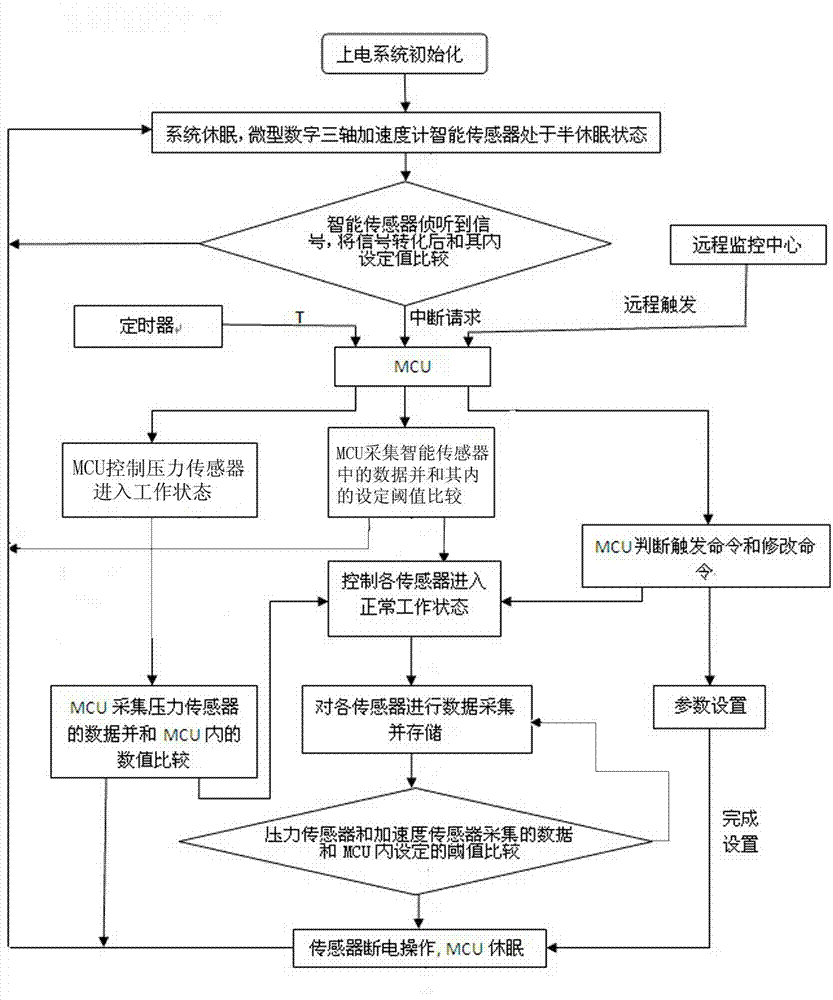

Low-power-consumption embedded type wireless sensor network node device

ActiveCN103052146AReduce power consumptionFully embeddedPower managementTransmission systemsData acquisitionEngineering structures

The invention relates to a wireless sensing network technology, particularly relates to a low-power-consumption embedded type wireless sensor network node device, and solves the problems of the conventional wireless sensor network node device that the power consumption is great, the conventional wireless sensor network node device cannot be embedded into an engineering structure body and the function is single. The low-power-consumption embedded type wireless sensor network node device comprises a sensor control module, a central comprehensive control module, a wireless radio frequency module and a power supply managing module. According to the low-power-consumption embedded type wireless sensor network node device disclosed by the invention, the problems that the power consumption is great and the wireless sensor network node device cannot be completely embedded and distributed when the wireless sensor network node device is deployed in the engineering structure body in a large scale are effectively solved; the problems of volume and data collection and treatment, and communication protocols and the like are solved; and under the preconditions that the safety and the reliability of data are ensured and a network node has good robustness, a wireless sensing network is used for carrying out remote monitoring on physical quantities inside the structure bodies including bridges, large-sized reservoir and dams, highway roadbeds, buildings and the like, so that the networked, intelligent and digital monitoring is realized.

Owner:TAIYUAN UNIV OF TECH

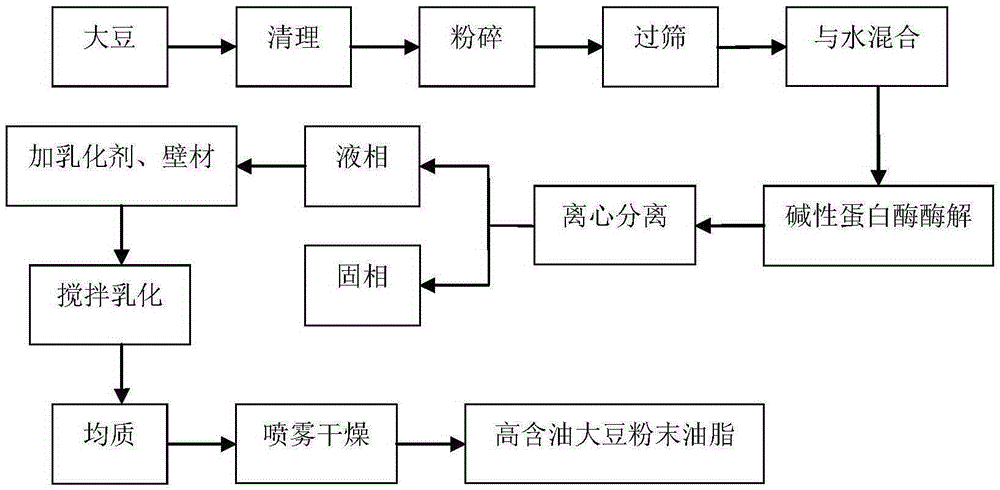

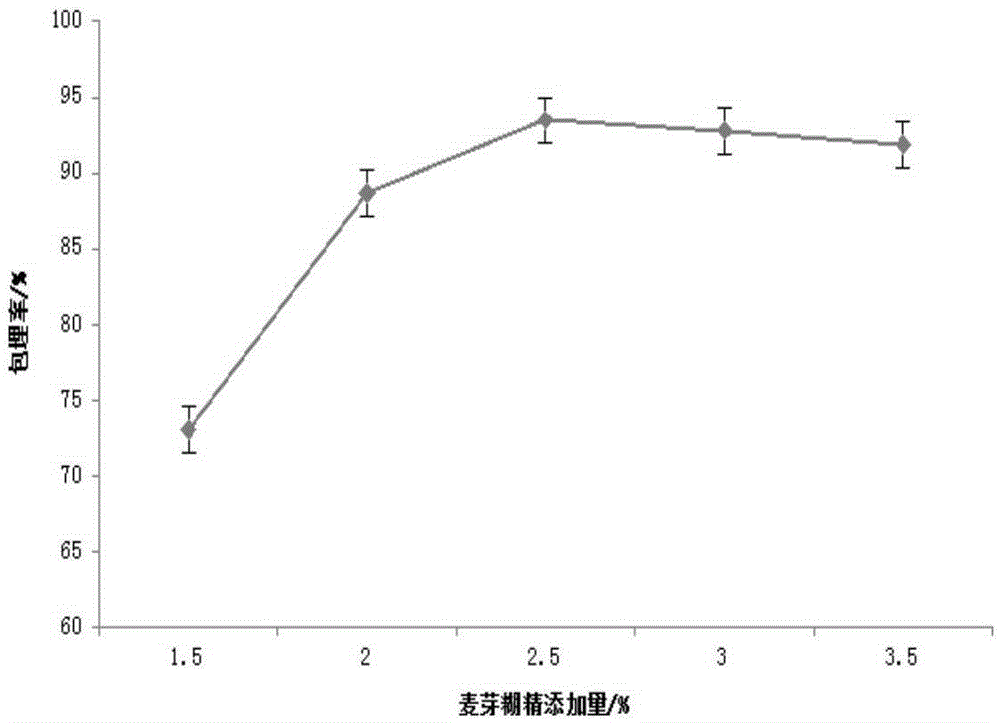

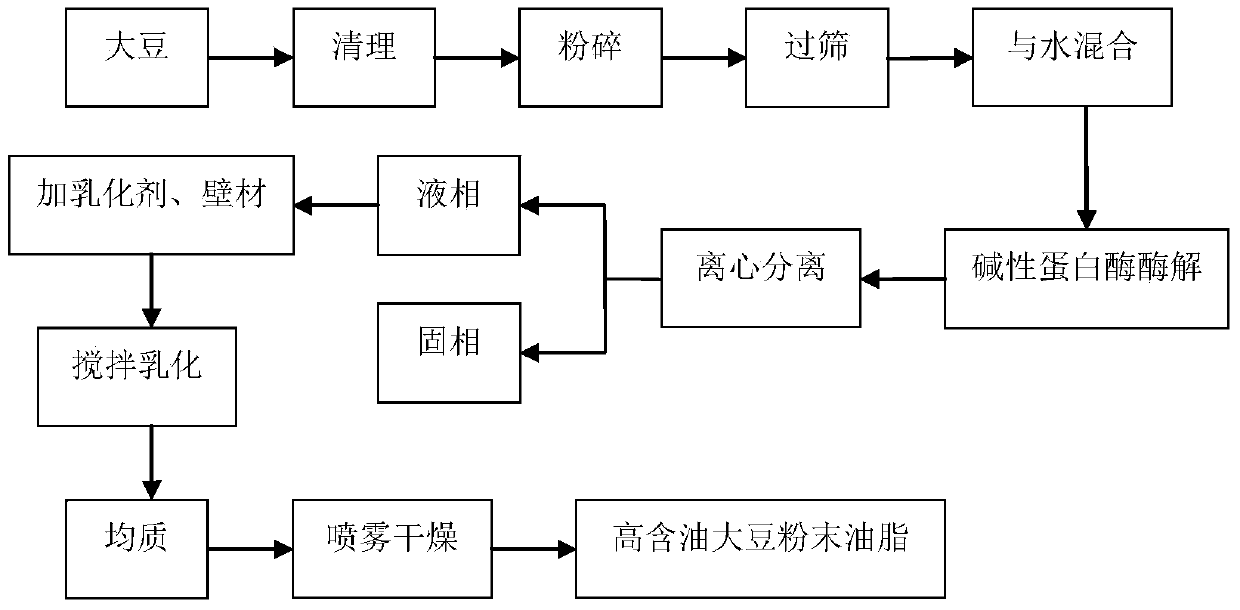

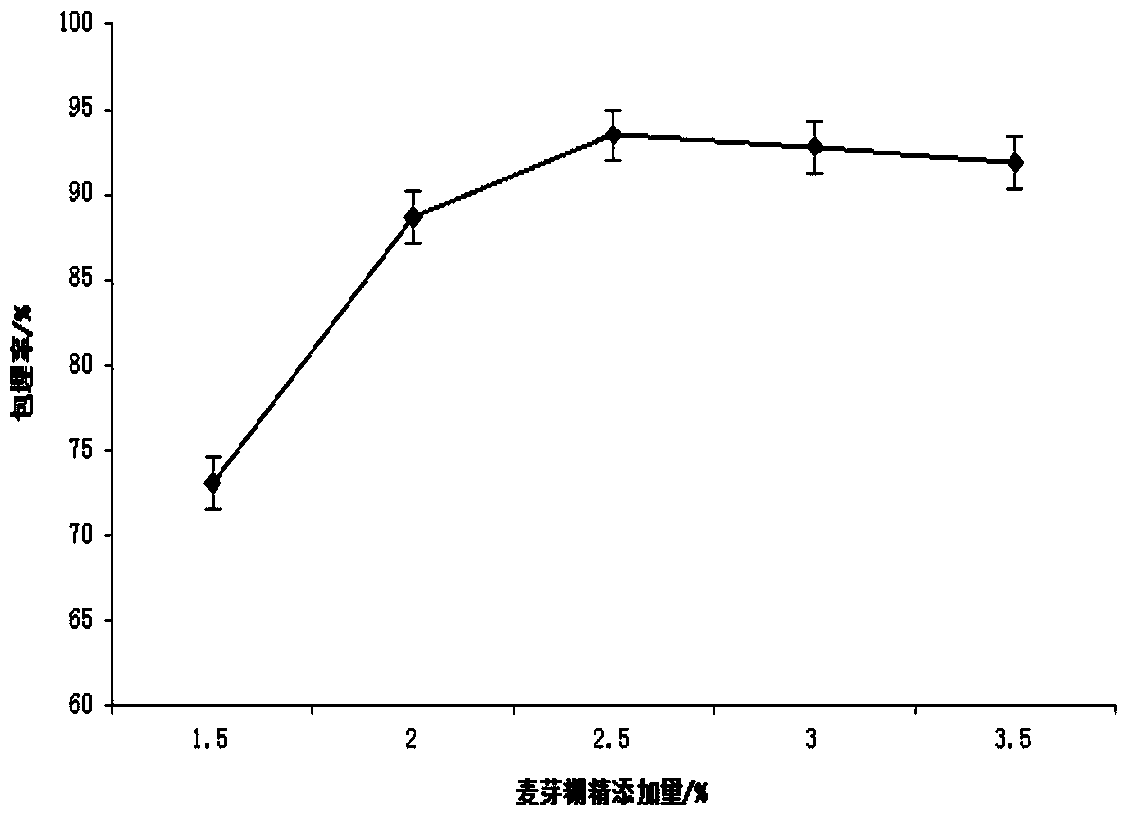

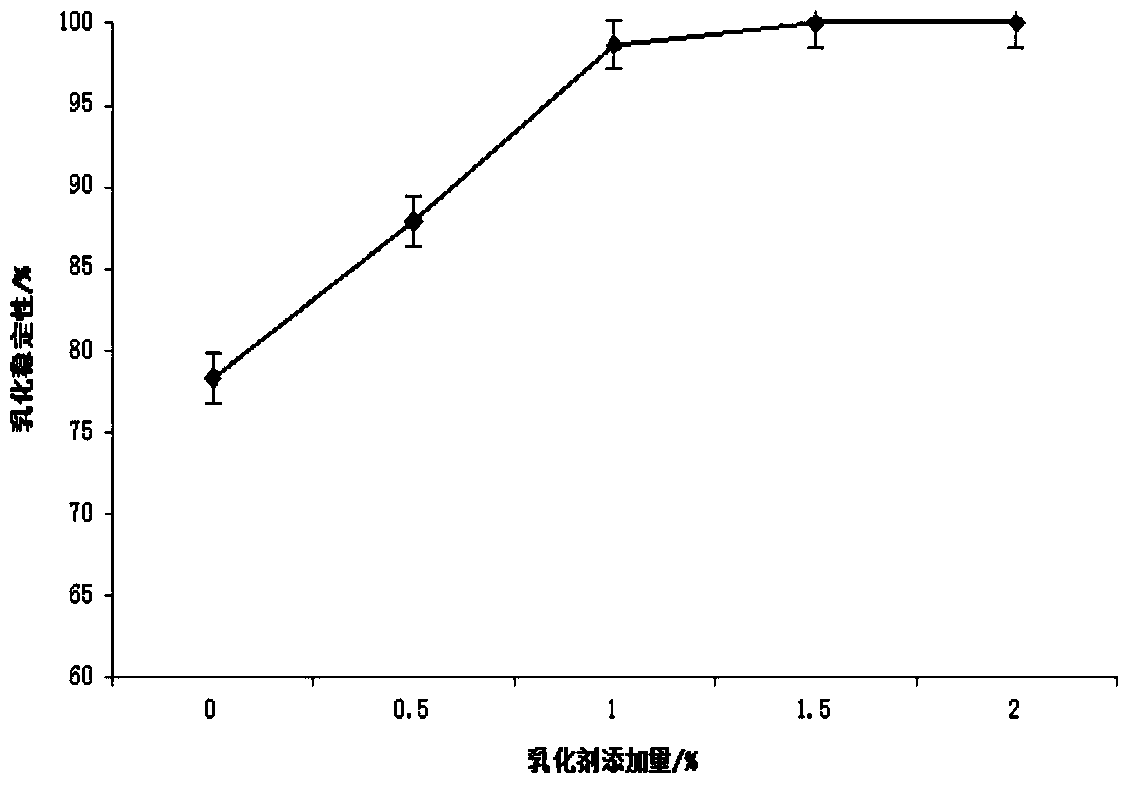

Preparation method of high oil containing soybean powdered oil

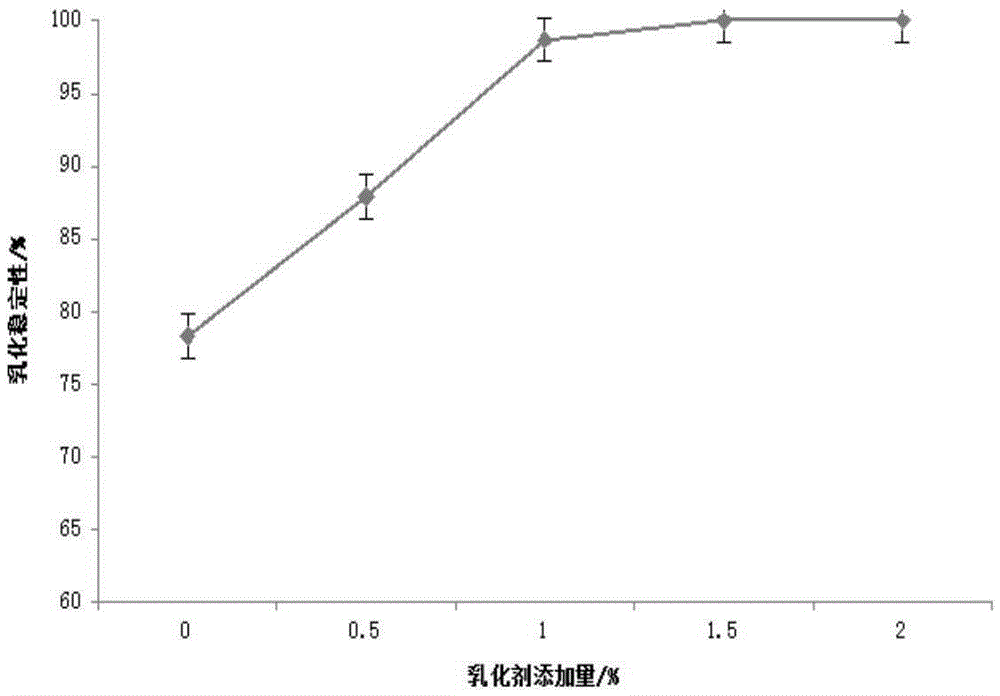

The present invention discloses a preparation method of a high oil containing soybean powdered oil and belongs to food processing technology. The method comprises the following steps: (1) soybeans are cleaned and crushed, the crushed soybeans are sieved to obtain soybean powder, the soybean powder is mixed with water to form a mixed liquid, an alkaline protease enzyme is added into the mixed liquid to conduct enzymolysis, and the enzymolyzed mixed liquid is centrifuged to obtain a liquid phase and a solid phase; (2) an emulsifier phospholipid and a wall material maltodextrin are added into the liquid phase to conduct emulsifying treatment; and (3) the emulsified liquid is subjected to high pressure homogenization process to obtain highly stable emulsion and then the emulsion is spray-dried to obtain the high oil containing soybean powdered oil. The technology is simple, the operation is safe, and the cost is low. The natural emulsion formed in the enzymolysis of soybeans can be used as a good raw material to prepare soybean powdered oil. Then an appropriate amount of phospholipids and maltodextrin are added in the preparation method. The prepared soybean powdered oil is good in quality, high in oil amount, free of oil leakage, and has broad application prospects.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

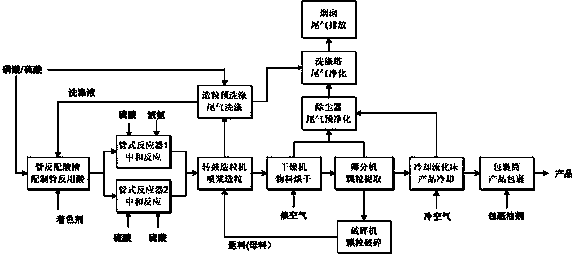

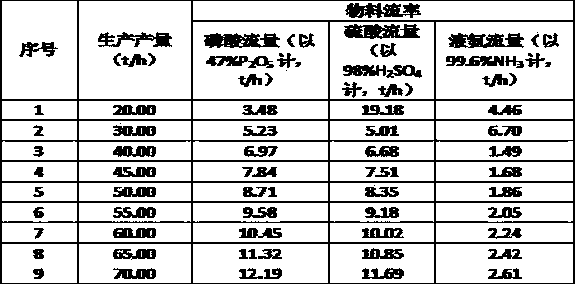

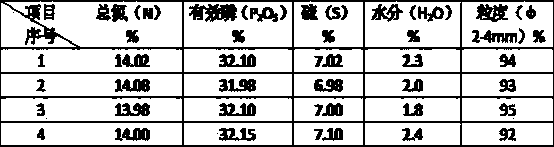

Production method of ammonium sulfate-ammonium phosphate composite fertilizer

InactiveCN104355734APromote growthImprove developmentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersO-Phosphoric AcidPhosphate

The invention discloses a production method of an ammonium sulfate-ammonium phosphate composite fertilizer. The composite fertilizer adopts the conventional ammonium phosphate double tubular reactor process; materials required for production mainly comprise strong phosphoric acid with concentration (P2O5) of 40 percent to 48 percent, anhydrous liquid ammonia with high purity and concentrated sulfuric acid with concentration of 90.0 percent to 98.5 percent; the strong phosphoric acid, the liquid ammonia and the concentrated sulfuric acid enter a tubular reactor in a certain ratio according to the specification of the product, neutralization reaction is performed to generate mixed slurry of ammonium sulfate and ammonium phosphate and ammonification and pelletization are carried out by a drum to form the ammonium phosphate-based nitrogen-phosphorus-sulfur (NPS) composite fertilizer. The product disclosed by the invention is rich in nutritional ingredients, such as ammonium nitrogen, soluble phosphate and soluble sulfate, so that the requirements of plant production for nitrogen, phosphorus and sulfur elements are met effectively, the functionality of the ammonium phosphate composite fertilizer is expanded, the added value of the product is improved, and an effective way is provided for promoting diversification of the fertilizer product.

Owner:WENGFU (GRP) CO LTD

Mooncakes and manufacturing method thereof

InactiveCN104365806AGood for healthFully embeddedDough treatmentBakery productsEdible oilHealthful food

The invention relates to mooncakes and a manufacturing method of the mooncakes. Each mooncake comprises a mooncake skin and a mooncake filling, the mooncake skins comprise, by weight, 15-25 parts of white granulated sugar, 5-13 parts of fine flour, 3-10 parts of edible oil and 7-13 parts of water, the mooncake fillings comprise, by weight, 1-10 parts of candied melon sugar, 1-10 parts of jujube paste, 1-6 parts of sugared mandarin, 0.5-5 parts of peanuts, 0.5-3 parts of sesame seeds, 0.5-3 parts of raisins, 1-6 parts of osmanthus fragrans, 3-7 parts of preserves, 4-7 parts of walnut kernels and 5-20 parts of edible oil. The manufacturing method includes the steps of skin making, filling making, filling stuffing and forming, baking and discharging the mooncakes out of an oven. The mooncakes are comprehensive in nutrition, good in color and taste, rich in mouthfeel, rich in protain, carbohydrate, vitamin, mineral element and the like, has various health care effects and the effects of resisting fatigue, soothing the nerves, nourishing the stomach, boosting the brain, beautifying, clearing heat and the like and are healthy food suitable for crowds in all age groups to eat.

Owner:向玲

Method for pre-charging lithium ionic cell

InactiveCN101399366AImprove performanceReduce wasteSecondary cells charging/dischargingPre-chargeEngineering

The invention relates to a method for precharging a lithium ion battery. The method comprises a step of aging an electric core which is filled with the electrolyte, a step of putting the electric core into a precharge cabinet, a step of precharging the electric core and a step of forming a negative pressure, the step of forming the negative pressure means the gas generated in the formation process is discharged from the inner of the electric core during the course of precharging. In particular, the step of forming the negative pressure is vacuumizing and the vacuumizing is performed during the course of precharging. By the method, the electrolyte can not overflow to the surface of the shell in the negative pressure condition, the corrosion of the shell caused by the electrolyte can be reduced, simultaneously the waste of the electrolyte is reduced, some preparatory protective operations are reduced, the technological process is simplified, and simultaneously the electric core is caused to form even SEI films during the forming course of the electric core, which improves the performance of the battery.

Owner:SHENZHEN BAK BATTERY CO LTD

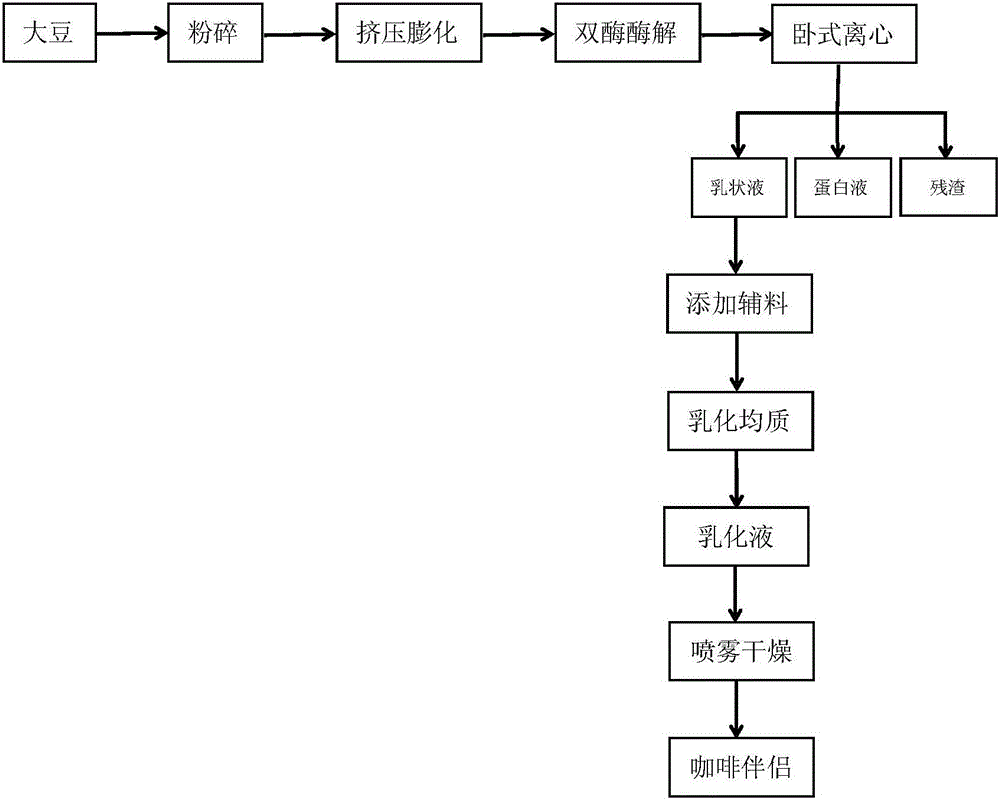

Method for preparing coffee-mate by using aqueous enzymatic emulsion

The invention discloses a method for preparing coffee-mate by using aqueous enzymatic emulsion. The method for preparing the coffee-mate by using the aqueous enzymatic emulsion comprises the following steps: (1), washing soybeans, pressing the washed soybeans into tablets, carrying out extrusion and expansion pre-treatments so as to obtain puffed materials, and then, mixing the puffed materials with water so as to obtain a mixed solution; (2), adjusting the temperature and the pH value of the mixed solution, adding alkaline protease and flavor protease so as to carry out enzymatic hydrolysis, adding enzymes to carry out enzymatic hydrolysis so as to obtain an enzymatic hydrolysate, deactivating the enzymes of the enzymatic hydrolysate, and then, carrying out centrifugal separation so as to obtain a protein solution, an emulsion and residues; and (3), adding auxiliary materials into the emulsion, carrying out emulsification reaction, performing high-pressure homogenization treatment, and then, carrying out spray-drying, so that novel soybean powder lipid with high oil content but without oil leakage is prepared. The natural emulsion formed while production of the soybean protein liquid during enzymatic hydrolysis of the soybeans is utilized as a good raw material for preparing the soybean coffee-mate; moreover, the wall materials, including beta-cyclodextrin, isolated soy protein and compounded emulsions, compounded antioxidants and sodium caseinate are added, so that the soybean coffee-mate with relatively good qualities is obtained.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Apple juice processing method for suppressing enzymatic browning

ActiveCN105724991AImprove color qualityInhibits enzymatic browningFood ingredientsBeta-CyclodextrinsEnzyme

The invention discloses an apple juice processing method for suppressing enzymatic browning. The apple juice processing method comprises the following steps: adding 0.002 to 0.008 g / ml of beta-cyclodextrin into apple juice, putting the mixture into an ultrasonic treatment kettle, and performing ultrasonic treatment at the ultrasonic power density of 40 to 100 W / cm2 for 5 to 20 min. According to the processing method, the activity of enzyme can be passivated under relatively lower temperature to suppress the enzymatic browning and avoid the influence caused by thermal processing on the physical and chemical properties of the apple juice, so that the nutritional components and the sensory quality of the apple juice can be better retained.

Owner:HUAZHONG AGRI UNIV

Fruit and vegetable juice processing method capable of inhibiting enzymatic browning

InactiveCN109619336AAvoid the influence of physical and chemical propertiesMaintain nutrientsFood ingredient functionsFood ultrasonic treatmentAdditive ingredientEnzyme inhibitor

The invention discloses a fruit and vegetable juice processing method capable of inhibiting enzymatic browning. The method includes the steps that 0.2-0.8 g / ml fructosan, 0.004-0.008 g / ml hesperidin and a 0.05-0.1 g / ml neuraminidase inhibitor are added into fruit and vegetable juice, the fruit and vegetable juice is put into an ultrasonic treatment kettle, ultrasonic treatment is carried out for 5-20 min at the ultrasonic power density of 40-100 W / cm<2>, static treatment is carried out for 10-15 minutes after ultrasonic treatment is stopped, and deoxidization sealing is rapidly carried out. Bymeans of the method, the enzymatic activity can be passivated at a low temperature, and enzymatic browning is inhibited; besides, the influence of thermal processing on the physical and chemical properties of the fruit and vegetable juice is avoided, and thus the nutritional ingredients and sensory quality of the fruit and vegetable juice are better maintained.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Method for producing pure chicken powder by embedding fat of chicken by utilizing inherent proteins of chicken

InactiveCN109007623ARetained proteinPreserve Fat RatioFood homogenisationFood denaturationBiotechnologySmall droplet

The invention discloses a method for producing pure chicken powder by embedding fat of chicken by utilizing inherent proteins of the chicken. The method for producing the pure chicken powder by embedding the fat of the chicken by utilizing inherent proteins of the chicken comprises the following steps: selecting a mixture in which chicken puree and skin-removed chicken breast are matched at a massratio of 4 to 1 as a chicken raw-material; performing high-temperature steaming on the chicken raw-material so as to have proteins denaturalized, and thus, a steamed chicken material composed of chicken and soup is obtained; refining the chicken and the soup together by using a colloid mill, and adding Novozymes's Flavourzyme (flavored proteases) and Protamex (compound proteases) into the refinedmaterials so as to be subjected to enzymatic hydrolysis; putting the materials after the enzymatic hydrolysis into a homogenizer, and performing high-speed shearing by utilizing mechanical force so as to have liquid oils in the materials fully whipped into small droplets; and then, performing spray-drying on the homogenized materials. According to the method, inherent fat of chicken is embedded by utilizing inherently contained proteins of the chicken, so that addition of other fillers and stabilizers is avoided; and thus, contents of protein and fat of the pure chicken powder are not influenced so as to have original protein-fat ratio of the chicken preserved to the maximum extent.

Owner:HENAN YONGDA MEIJI FOOD CO LTD

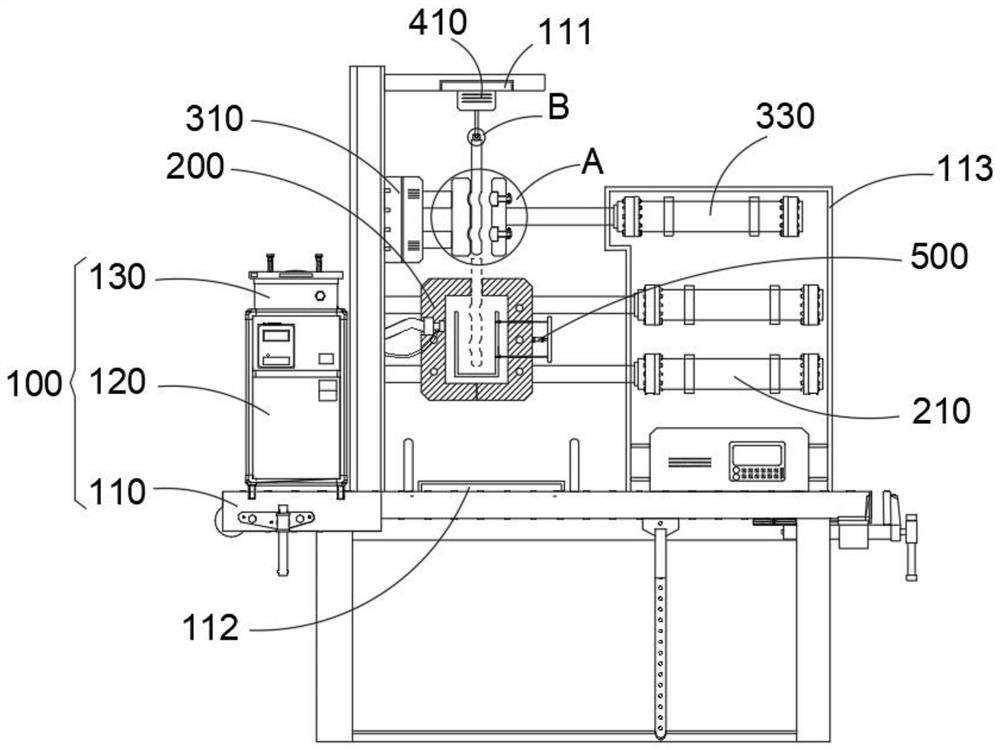

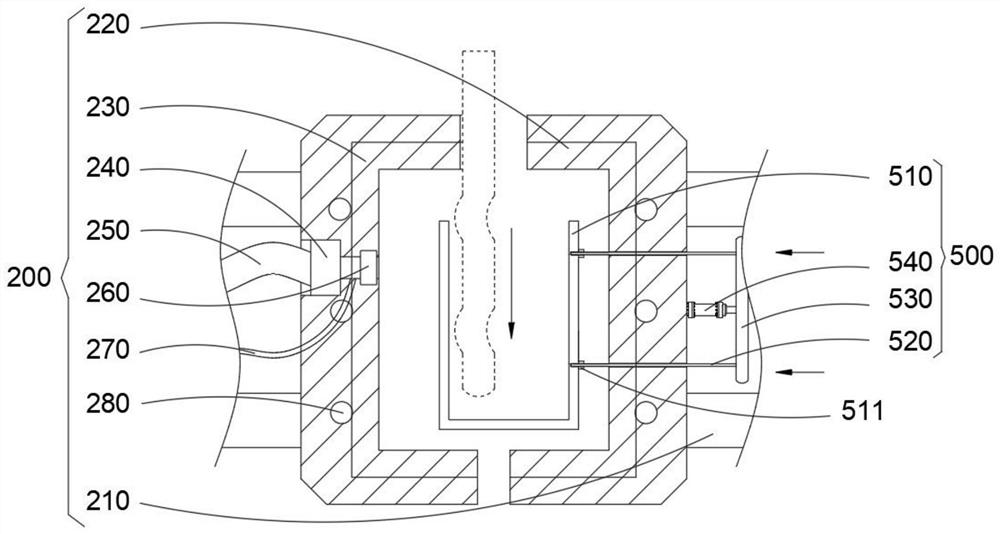

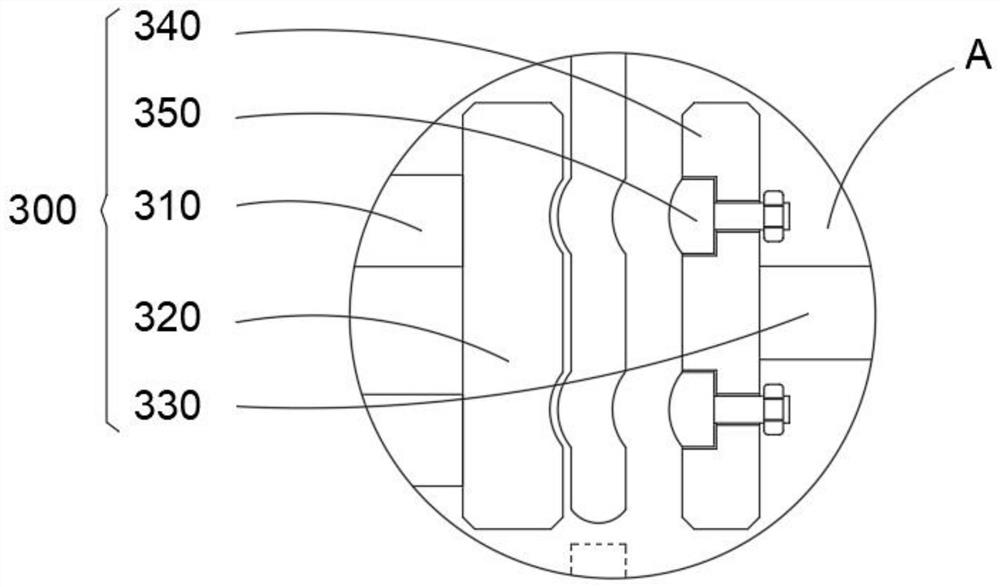

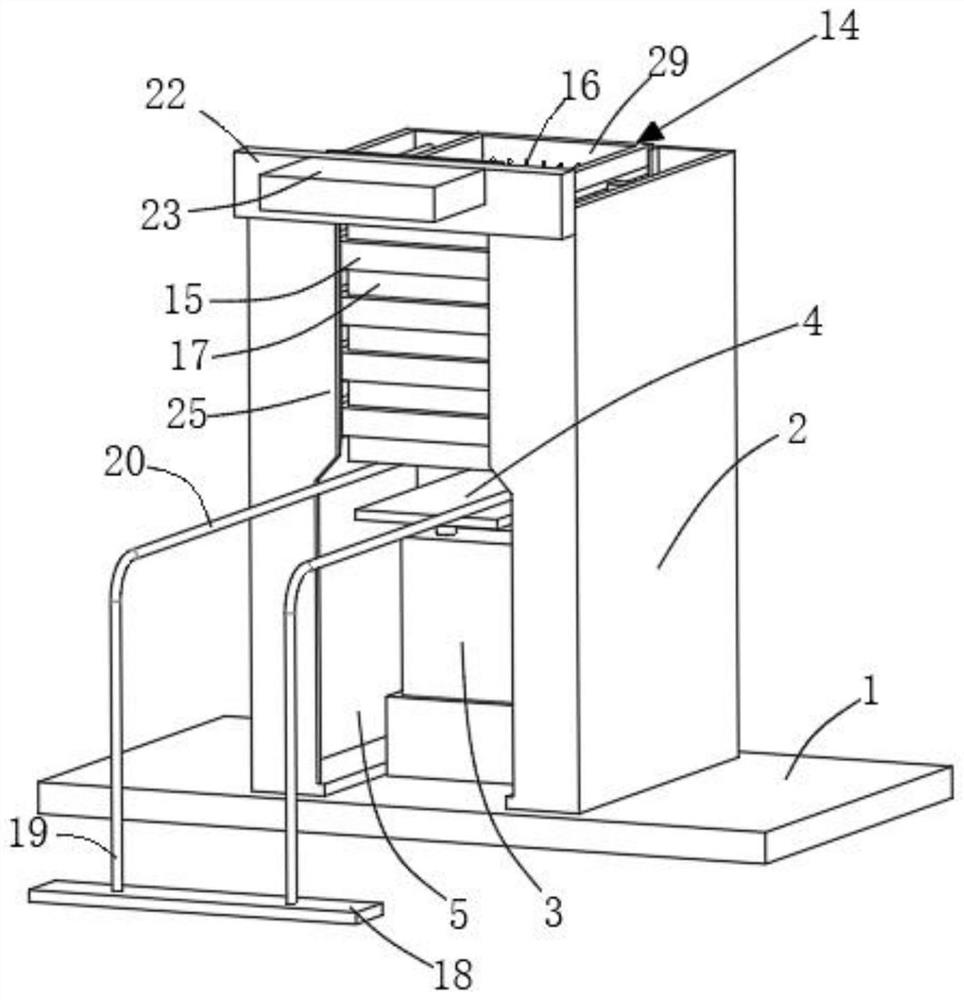

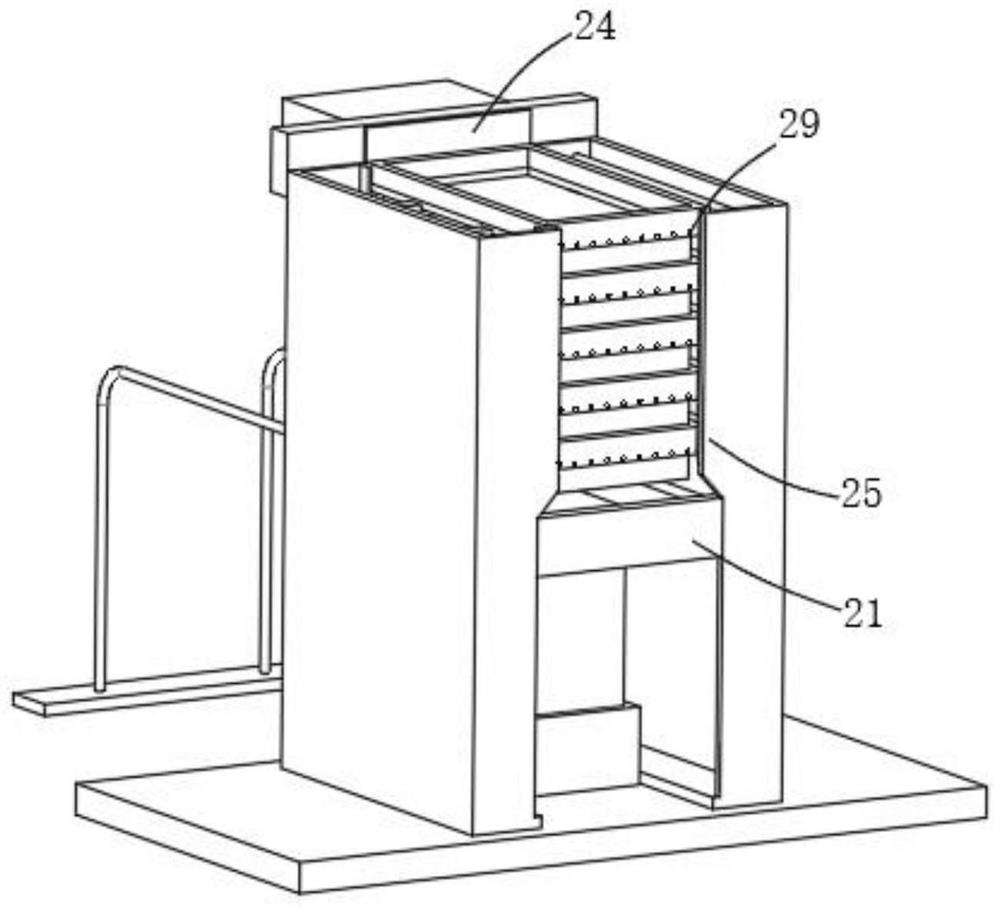

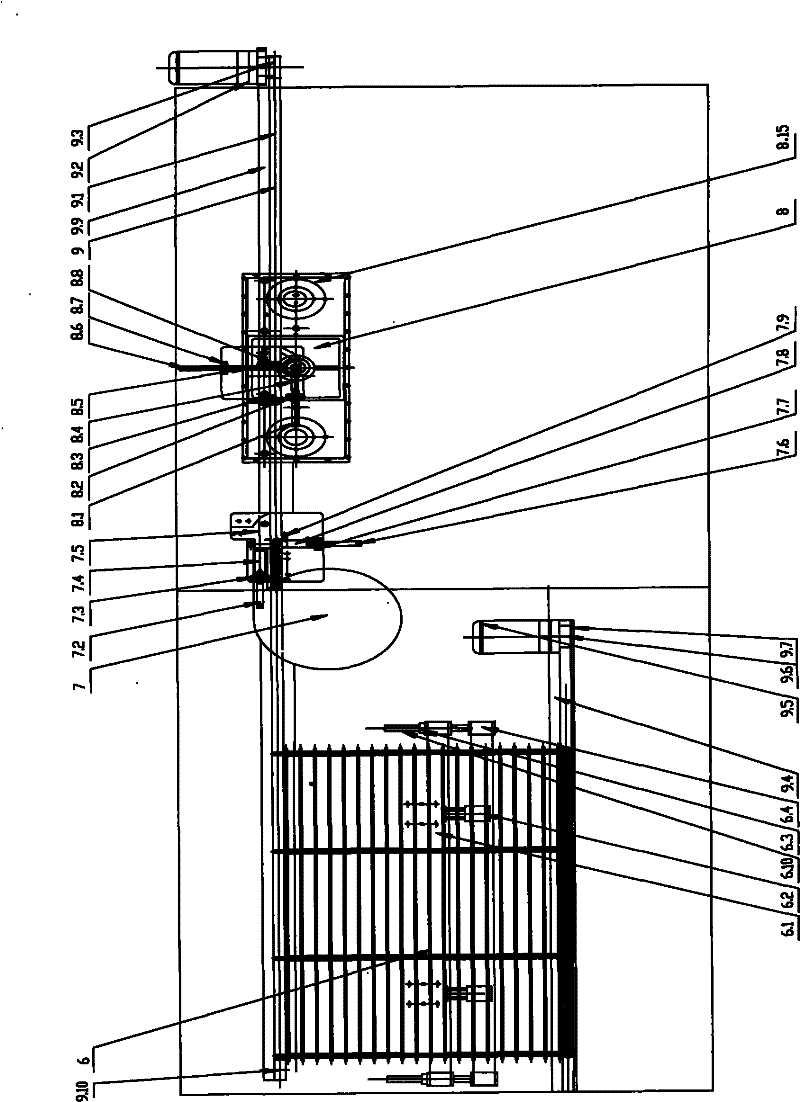

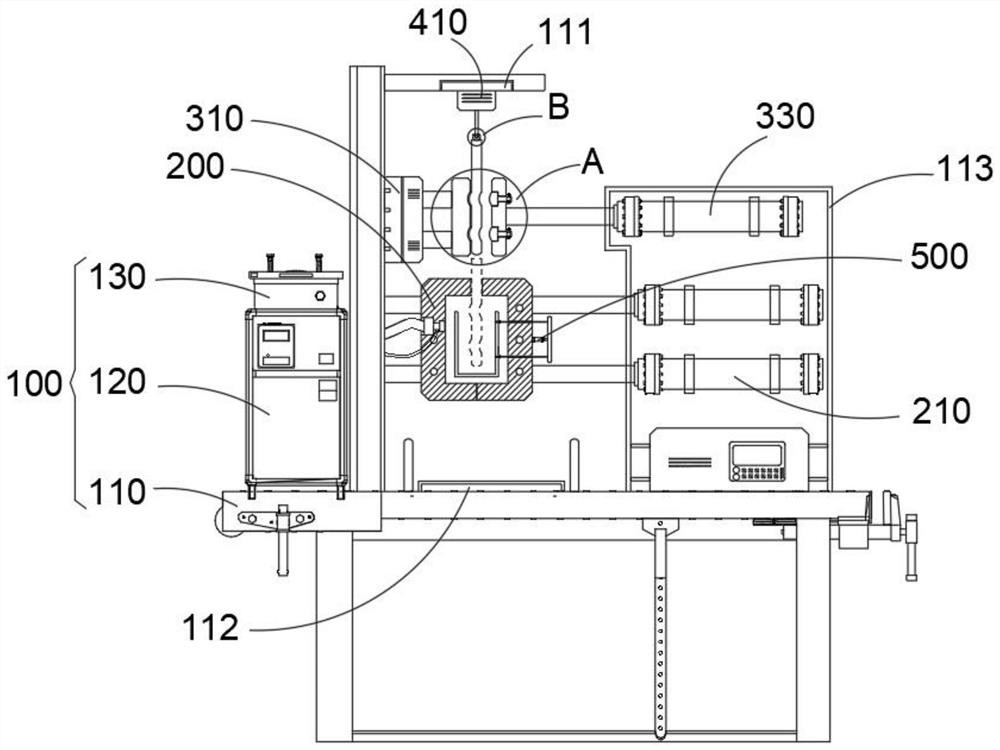

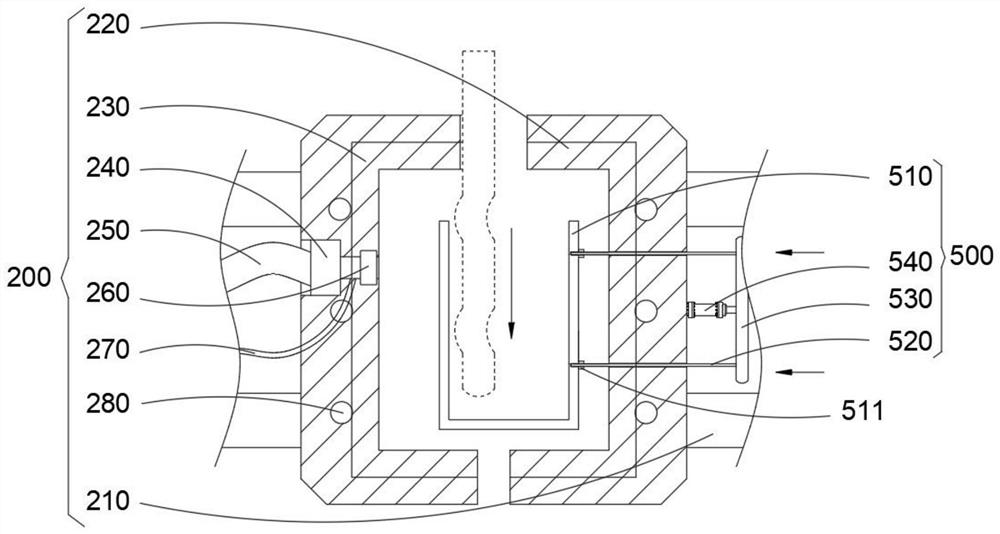

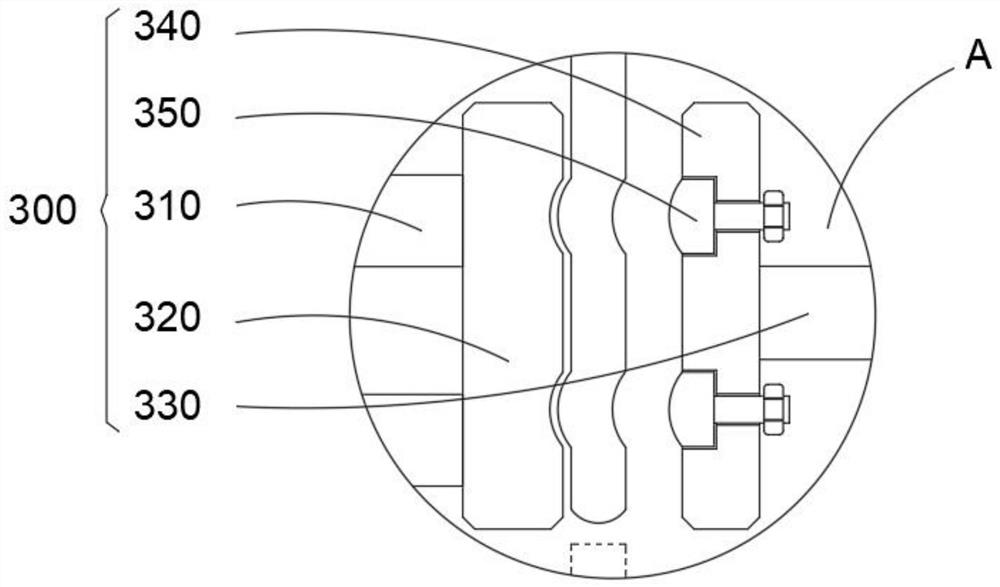

Metal piece embedding equipment for plastic product production

ActiveCN113442371AImprove connection strengthImprove efficiencyCoatingsManufacturing engineeringElectrophoreses

The invention belongs to the technical field of plastic product production, and particularly relates to metal piece embedding equipment for plastic product production. The metal piece embedding equipment comprises an injection molding mechanism, a forming mechanism, a pressing mechanism, a feeding mechanism, a positioning mechanism and an opening changing mechanism, the injection molding mechanism comprises a machine body, an injection molding machine for injection molding operation and a cooling machine for cooling operation; and the forming mechanism comprises a first hydraulic cylinder which is installed on the machine body and used for driving operation. According to the equipment, the forming mechanism is combined with the pressing mechanism and the feeding mechanism for use, so that a metal piece can enter the space between a movable mold and a fixed mold through conveying and extrusion deformation and then is subjected to injection molding, and compared with the prior art, the equipment has the advantages that the metal piece can be connected in a wrapping manner under the condition of controlling the depth, the connecting strength of plastic and metal is remarkably improved, and the surface of the metal piece is extruded through integrated operation. Compared with electrophoresis and corrosion means, the integrated operation is more convenient and faster, higher in efficiency, free of influence on the connecting effect and convenient to popularize and use.

Owner:XINGHUA SANCHENG PRECISION FORGING

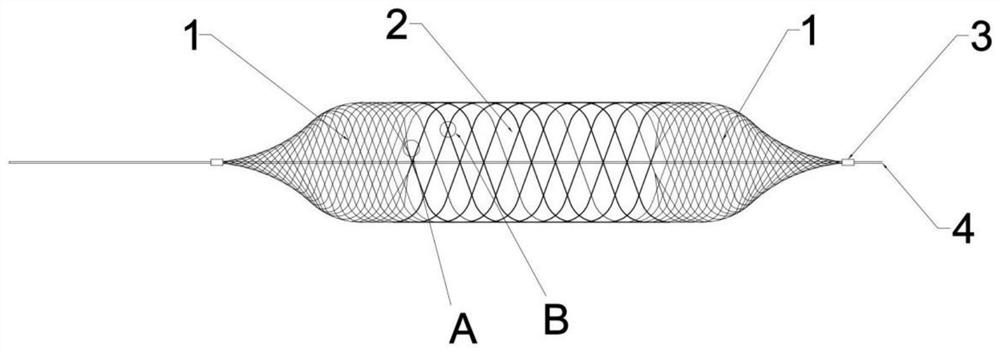

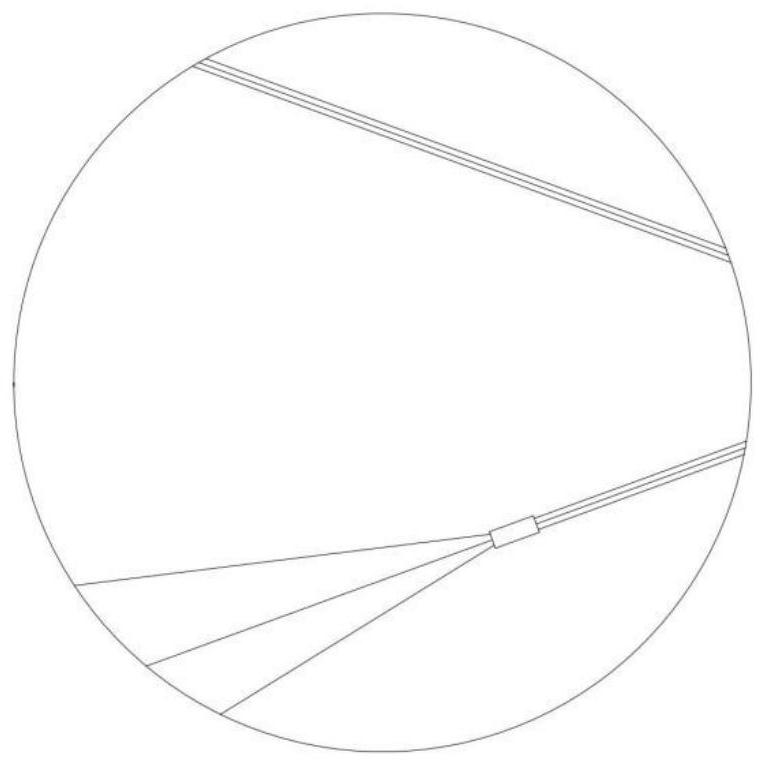

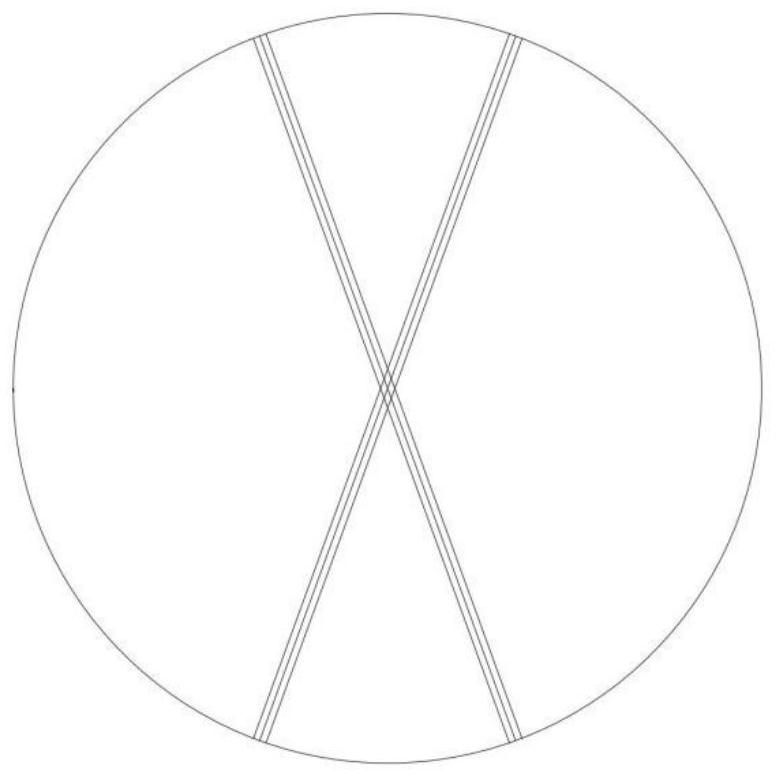

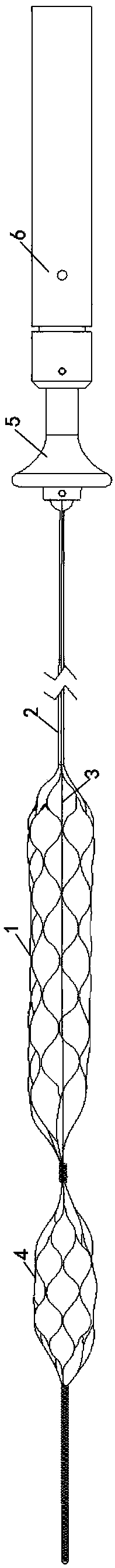

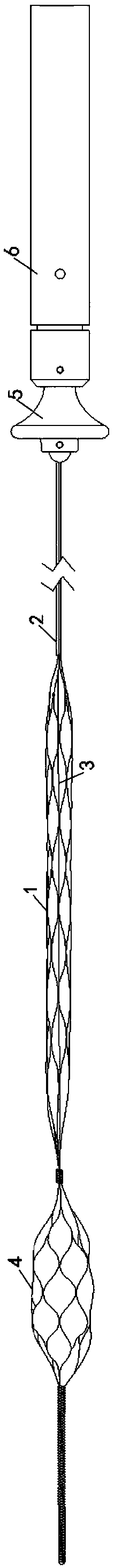

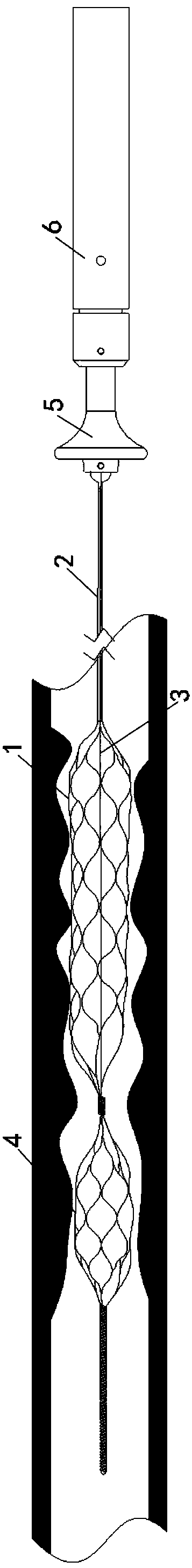

Integrated thrombectomy stent

The invention discloses an integrated thrombectomy stent. The integrated thrombectomy stent comprises filter nets, a thrombectomy stent body, net-end constraint points and a pushing rod. According tothe integrated thrombectomy stent, a thrombus capturing device special for protecting far-end and near-end blood vessels is arranged; closed dense net structures at two ends of the thrombus capturingdevice not only can trap a large main thrombus but also can capture stripped small thrombi and other foreign matter possibly causing embolism, thereby preventing small thrombus clots from flowing intoother near-end or far-end blood vessels; a near-end thrombus filter net of the integrated thrombectomy device is fixed to the pushing rod, while a far-end thrombus filter net can move in the axial direction, and can flexibly regulate and control stretching and retracting of the stent; an integrated structure of the thrombus filter nets and the net-shaped thrombectomy stent is used, and thus, while the wrapping performance of the thrombectomy device on thrombi is improved, the risk that a thrombectomy stent is separated from thrombus filter nets due to the insufficient closing force of the thrombus filter nets in a split structure is effectively avoided.

Owner:JIANGSU NOWYON MEDICAL CO LTD

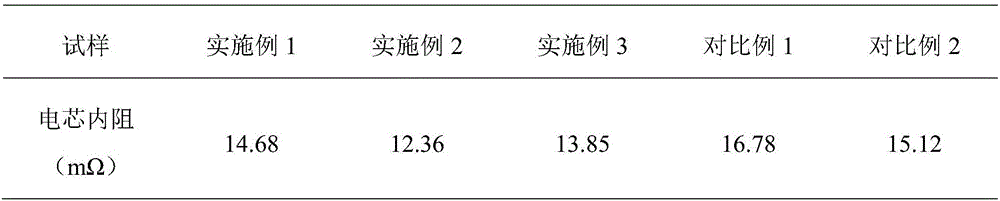

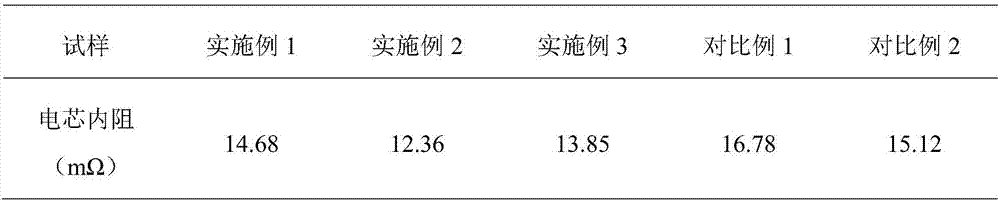

A composite conductive paste for positive and negative electrodes of a lithium ion battery and a preparation method thereof

ActiveCN106229032AImprove cycle lifeIncrease energy densityCell electrodesNon-conductive material with dispersed conductive materialConductive pasteElectrical battery

The invention is applicable to the technical field of lithium ion batteries and provides a composite conductive paste for positive and negative electrodes of a lithium ion battery and a preparation method thereof. The composite conductive paste for the positive and negative electrodes of the lithium ion battery comprises the following components in parts by weight: 5.0 to 7.5 parts of carbon nanotubes, 0.3 to 0.6 parts of a dispersing agent and 90 to 95 parts of N-Methyl pyrrolidone; the carbon nanotubes are composed of large-diameter carbon nanotubes and small-diameter carbon nanotubes, wherein the diameter of each large-diameter carbon nanotube is 30 to 150 nm, and the diameter of each small-diameter carbon nanotube is 1 to 30 nm, and the diameter difference between the large-diameter carbon nanotube and the small-diameter carbon nanotube is 15 nm or more; and the weight ratio of the large-diameter carbon nanotubes to the small-diameter carbon nanotubes is (3-7) :( 7-3). The composite conductive paste for the positive and negative electrodes of the lithium ion battery provided by the invention can form a good conductive network with the active materials, and thus the internal resistance of the lithium ion battery is reduced, and the lithium ion battery can have electrochemical properties such as excellent cycle life and energy density.

Owner:SHENZHEN SSZK NEW MATERIALS CO LTD

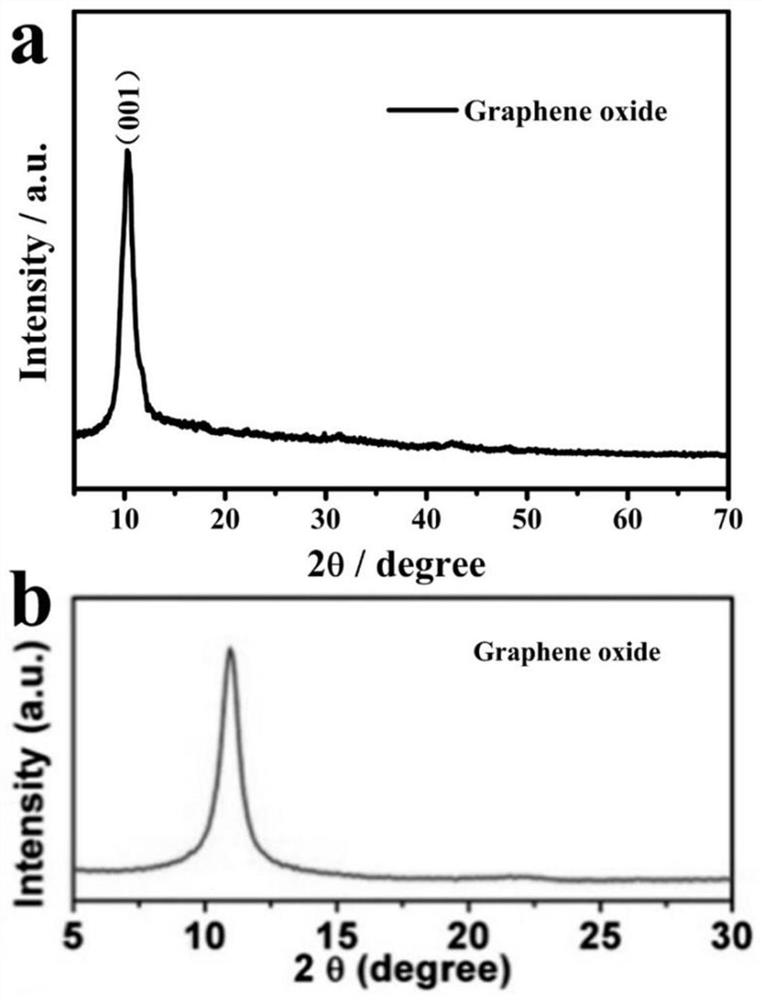

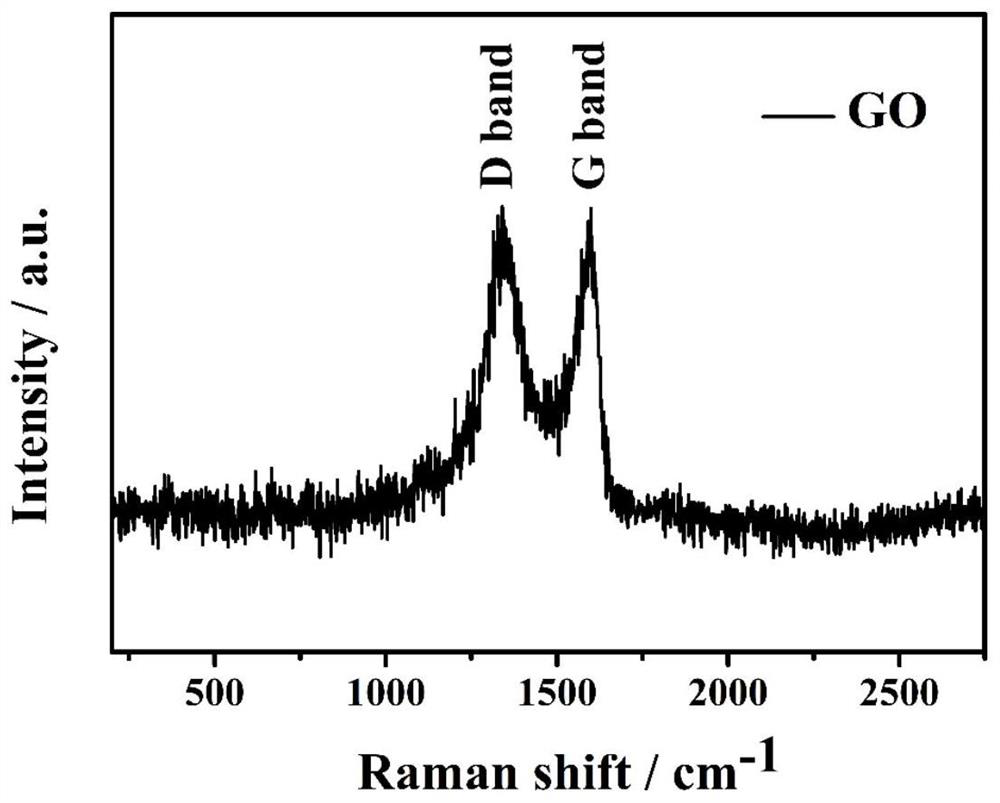

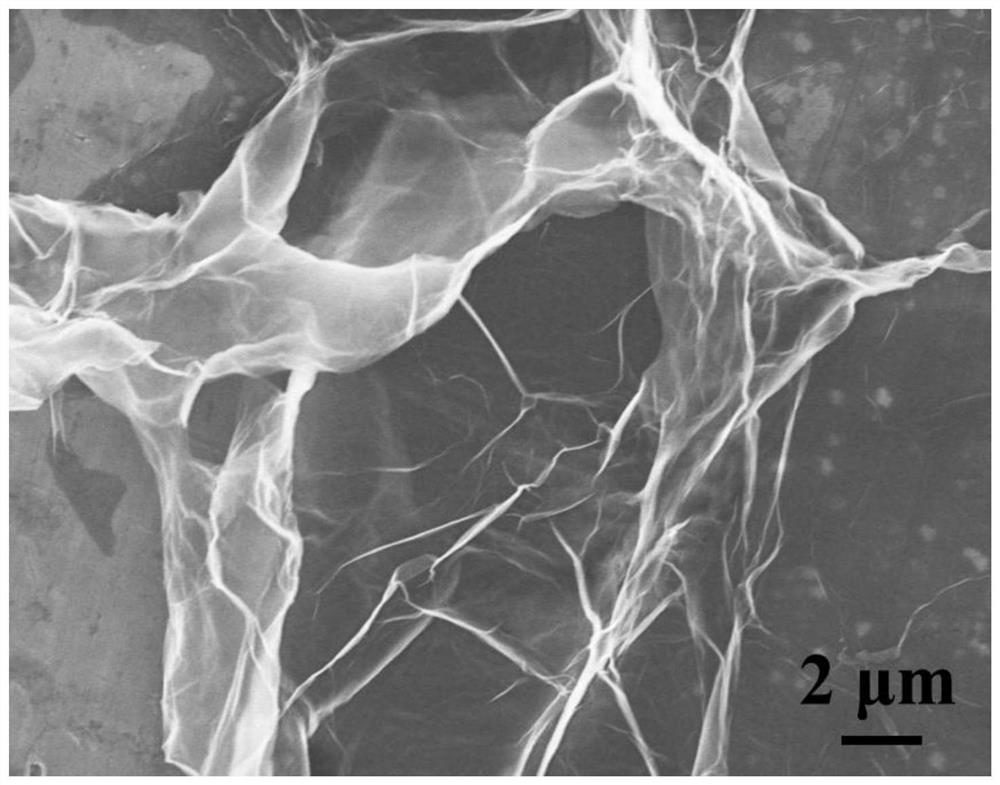

Low-cost hydrothermal-assisted method for preparing graphene oxide

ActiveCN112225211AImprove efficiencyImprove securityMaterial nanotechnologyGrapheneGraphite oxideLamellar structure

The invention discloses a low-cost hydrothermal-assisted method for preparing graphene oxide. According to the method for preparing the graphene oxide, the graphene oxide is oxidized and stripped through cooling and hydrothermal assistance. The graphene oxide obtained by the method has an independent lamellar structure. Compared with other chemical methods, independent two-dimensional layered graphene oxide can be obtained, compared with other physical methods, the method can effectively improve the stripping efficiency of graphite, and meanwhile, the method has the advantages that the operation is simple and safe, and the prepared graphene oxide has high efficiency. It is proved that the low-cost hydrothermal assistance method is a widely-popularized method for preparing graphene oxide.

Owner:QILU UNIV OF TECH

Single-phase cylindrical linear oscillation motor

InactiveCN111030414AIncrease effective fluxSimple manufacturing processReciprocating/oscillating/vibrating magnetic circuit partsMagnetic circuit stationary partsElectric machineMagnetic media

The invention discloses a single-phase cylindrical linear oscillation motor, and the motor rotor is provided with a permanent magnet ring, thereby improving the effective magnetic flux of the motor. The rotor sleeve is made of a non-magnetic medium, so that the material consumption of the motor iron core is effectively reduced; by adopting the stator iron core with the annular groove inside, the concentric winding coil can be fully embedded in the stator groove, the motor manufacturing process is simplified, and the groove utilization rate is improved; and the stator grooves are separated by the non-magnetic rings, so that the magnetic circuit of the stator core is divided, a short magnetic circuit is formed, and the propulsive force of the motor is increased.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Preparation method of cheese-flavored microencapsulated essence

The invention discloses a preparation method of cheese-flavored microencapsulated essence. Raw materials for preparing the cheese-flavored microencapsulated essence comprise purified water, emulsifiedmodified starch, sodium benzoate, maltodextrin, whole milk powder and a cheese essence base. Instrument devices comprise a weighing device, a heater, a stirring kettle, a high-speed shearing kettle,a heating kettle, a homogenizer, a spray tower and a sieving machine. The preparation method comprises the following steps: 1, the raw materials are repeatedly weighed and proportioned; 2, the purified water, emulsified modified starch, sodium benzoate, maltodextrin and whole milk powder are sequentially added into the stirring kettle, and are stirred; 3, a material obtained in the stirring kettleis added into the high-speed shearing kettle, and is sheared; 4, the cheese essence base is added into the high-speed shearing kettle, and shearing is performed; 5, the obtained sheared material is homogenized by the homogenizer; and 6, the homogenized material is added into the spray tower and is powdered. Repeated checking of the weights in the weighing and feeding process ensures the weighingaccuracy.

Owner:安徽骉犇食品科技有限公司

A method for processing apple juice capable of inhibiting enzymatic browning

ActiveCN105724991BImprove color qualityInhibits enzymatic browningFood ingredientsBeta-CyclodextrinsOrganoleptic

The invention discloses an apple juice processing method for suppressing enzymatic browning. The apple juice processing method comprises the following steps: adding 0.002 to 0.008 g / ml of beta-cyclodextrin into apple juice, putting the mixture into an ultrasonic treatment kettle, and performing ultrasonic treatment at the ultrasonic power density of 40 to 100 W / cm2 for 5 to 20 min. According to the processing method, the activity of enzyme can be passivated under relatively lower temperature to suppress the enzymatic browning and avoid the influence caused by thermal processing on the physical and chemical properties of the apple juice, so that the nutritional components and the sensory quality of the apple juice can be better retained.

Owner:HUAZHONG AGRI UNIV

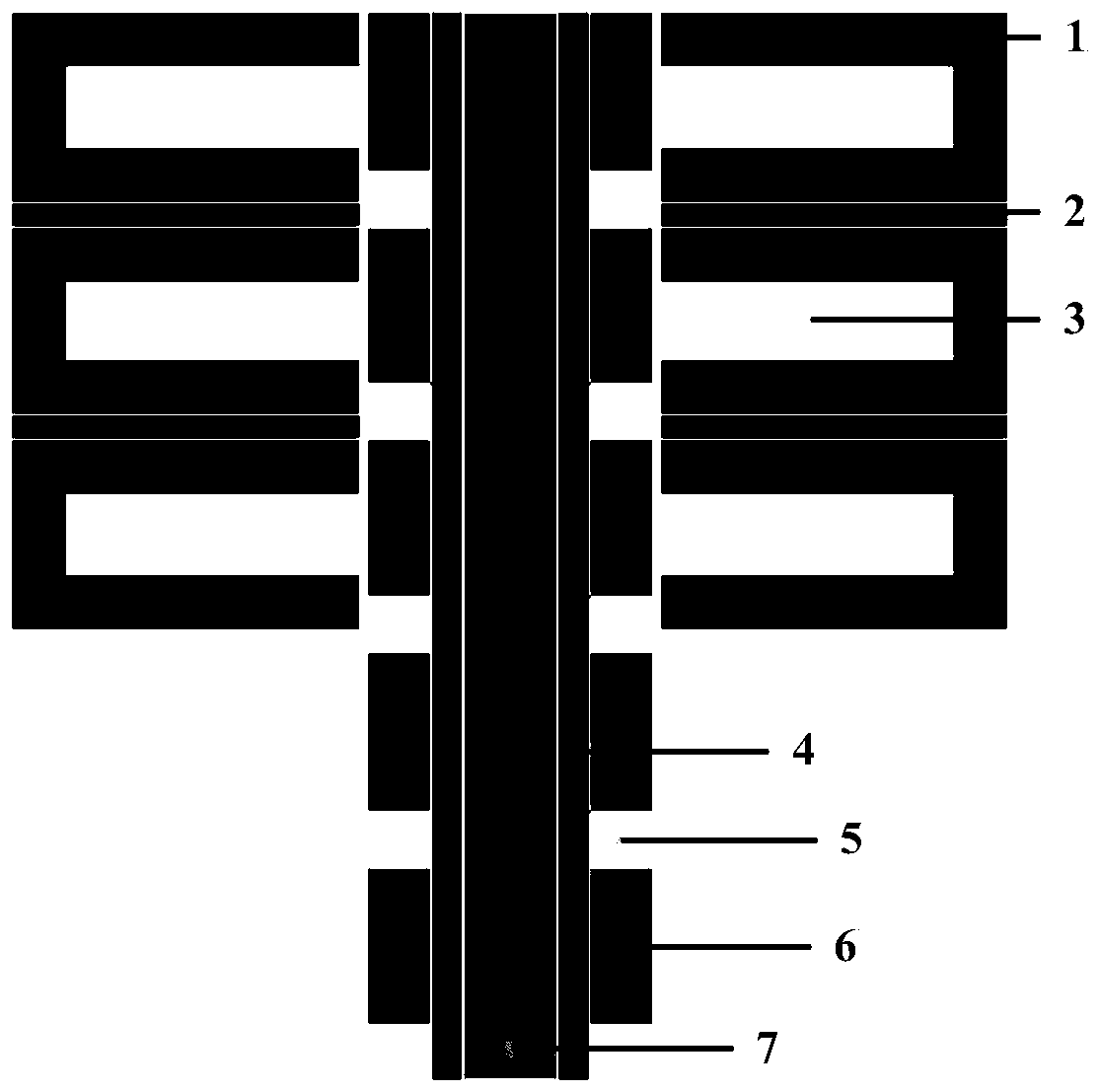

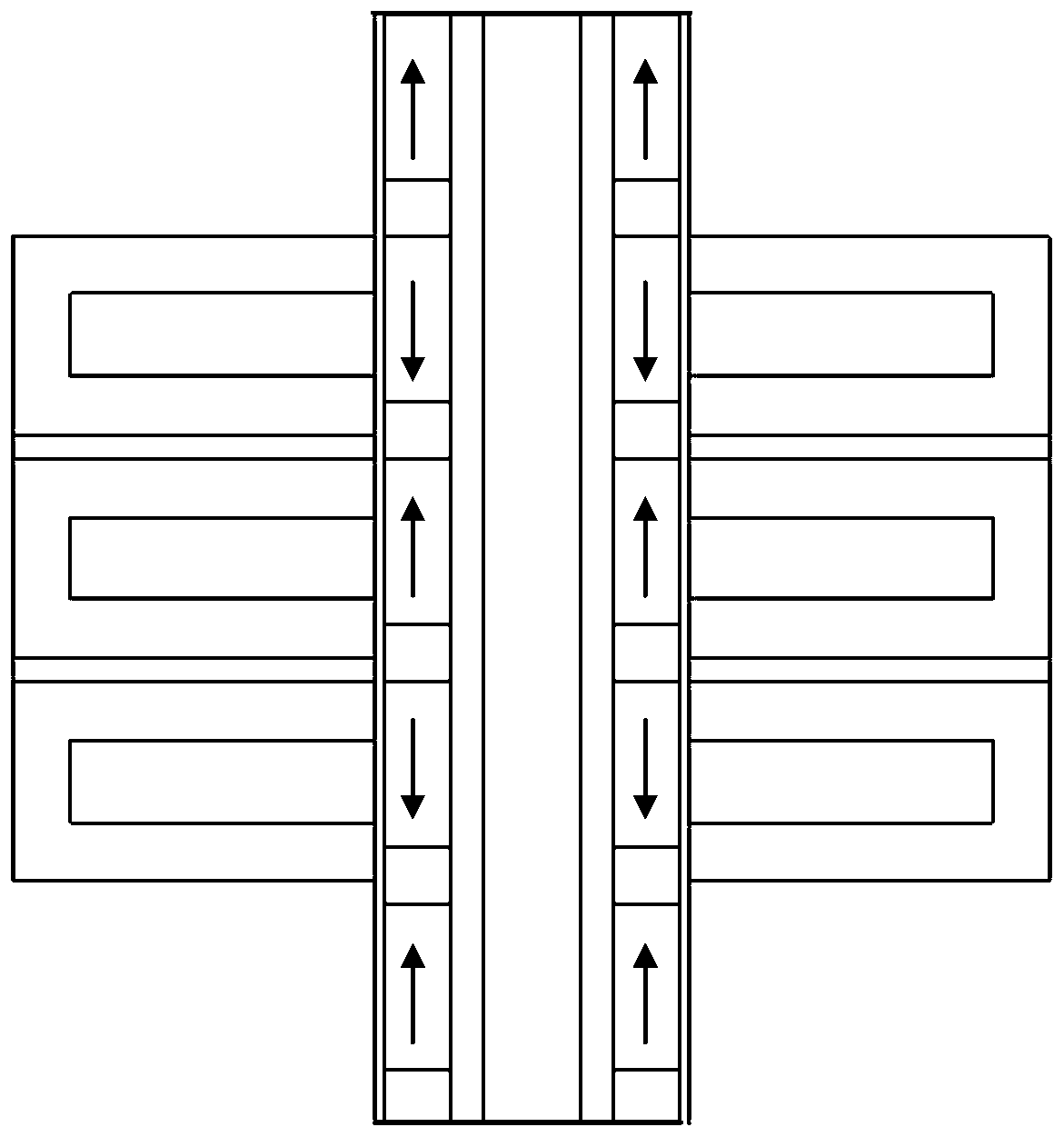

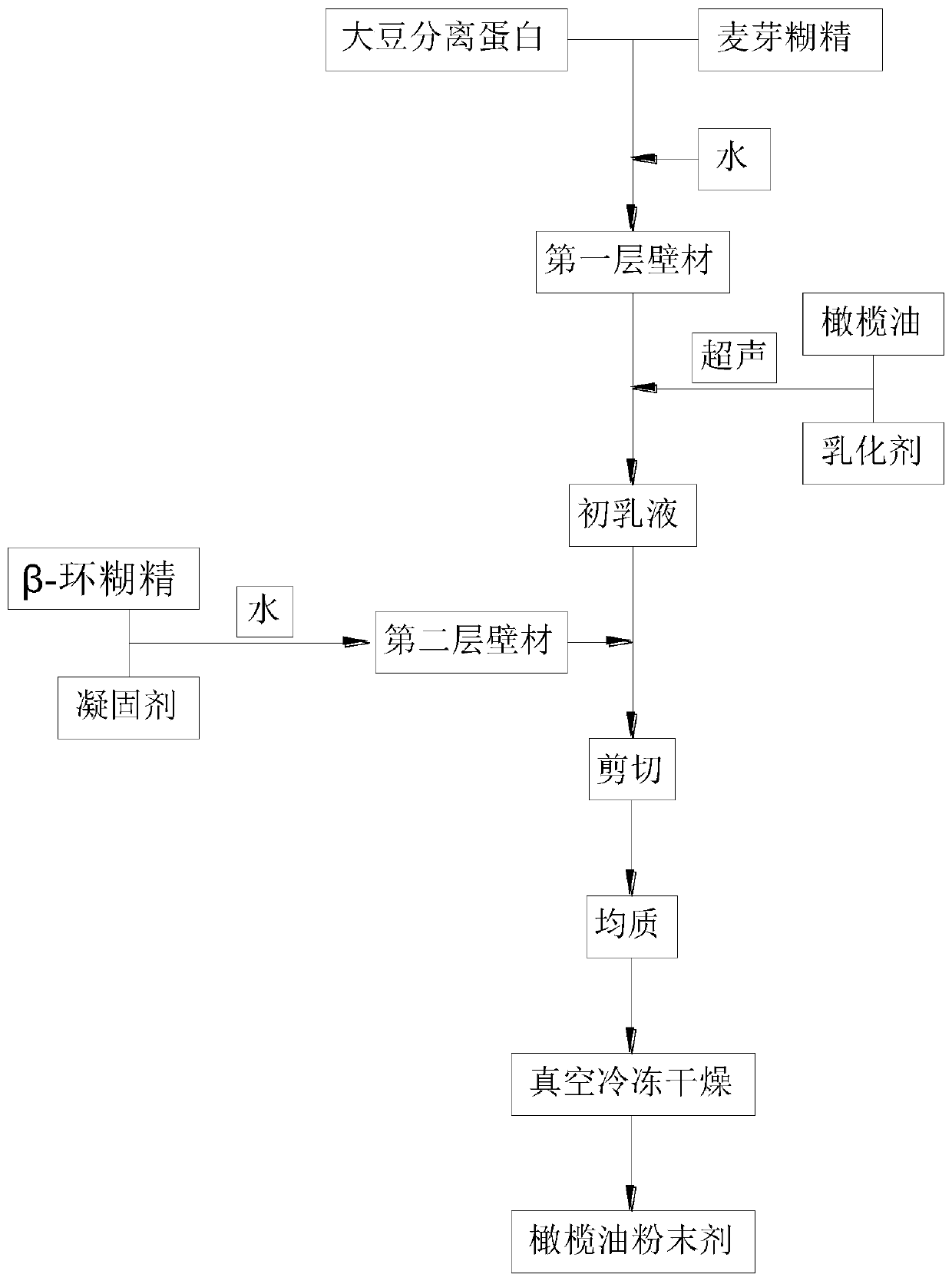

Preparation method of olive oil powder, and olive oil powder

ActiveCN111184076AGood embedding effectIsolated contactFood freezingLipidic food ingredientsEmulsionFreeze-drying

The invention provides a preparation method of olive oil powder, and the olive oil powder, and relates to the technical field of olive oil processing. The preparation method comprises the following steps: S1, combining soy isolate protein and maltodextrin, and adding water for dissolving to obtain a solution A; S2, adding an emulsifier into water for dissolution, then adding olive oil, performinguniform mixing, and performing ultrasonic treatment to obtain a solution B; S3, heating water to 80-90 DEG C, adding beta-cyclodextrin and a coagulator, performing stirring for dissolving, and coolingobtained mixture to 45-65 DEG C to obtain a solution C; S4, adding the solution B into the solution A, performing uniform mixing, and performing shearing and homogenizing to prepare a primary emulsion; S5, adding the primary emulsion into the solution C, performing uniform mixing, and performing shearing and homogenizing to obtain a final emulsion; S6, putting the final emulsion into a vacuum freeze drying oven, and performing drying for 24-30 hours at a temperature of -30 to-50 DEG C; and S7, crushing the dried material by using a crusher, and performing screening by using a screen to obtainthe olive oil powder. The olive oil powder is embedded by adopting a double-layer wall material, is strong in product quality stability, is not easy in damage and oil leakage, and is convenient to store and transport.

Owner:GUANGYUAN RONGSHENGYUAN FOOD

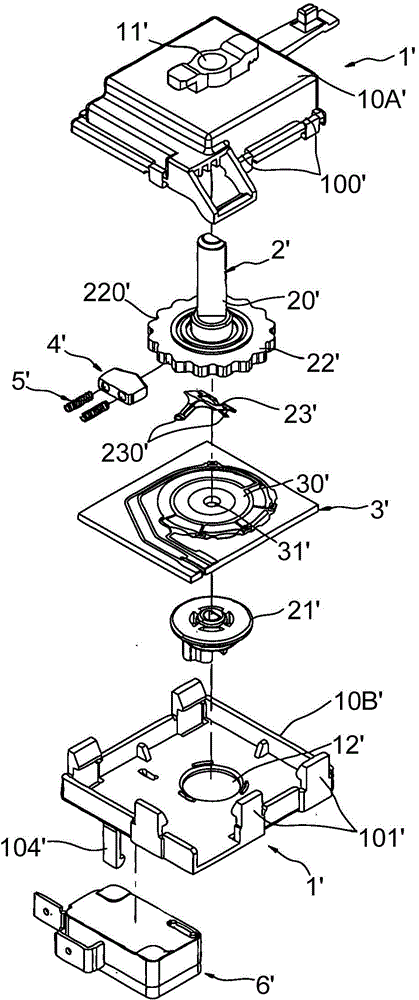

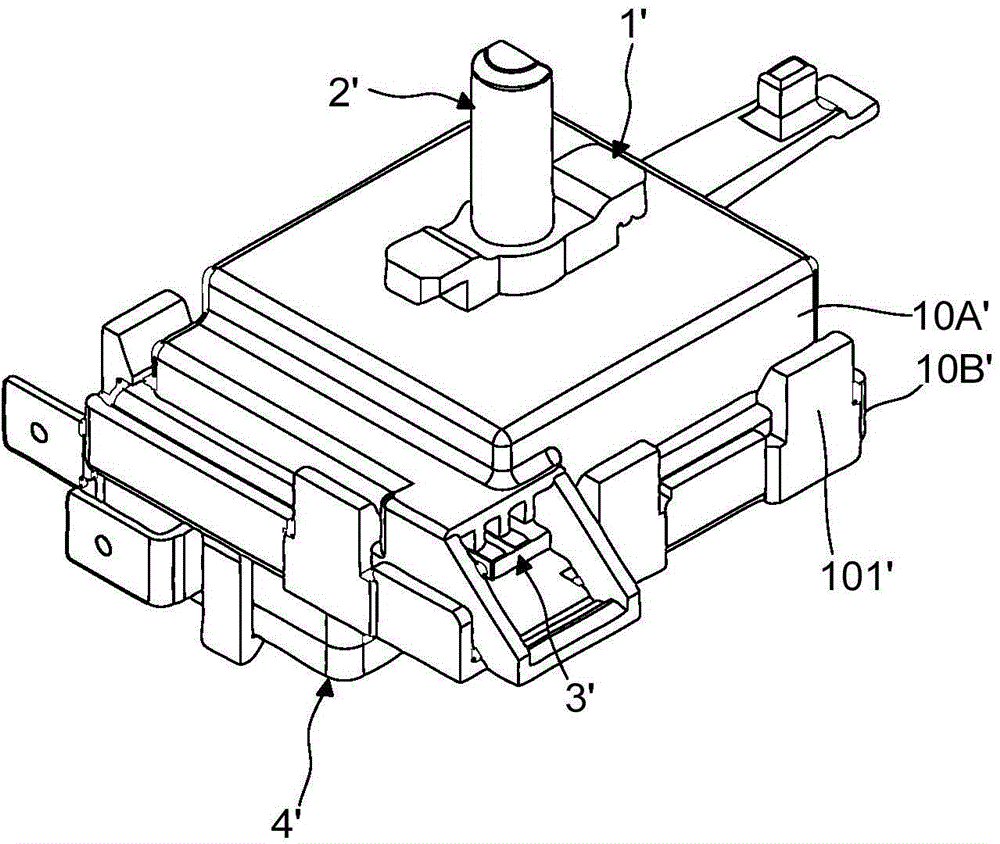

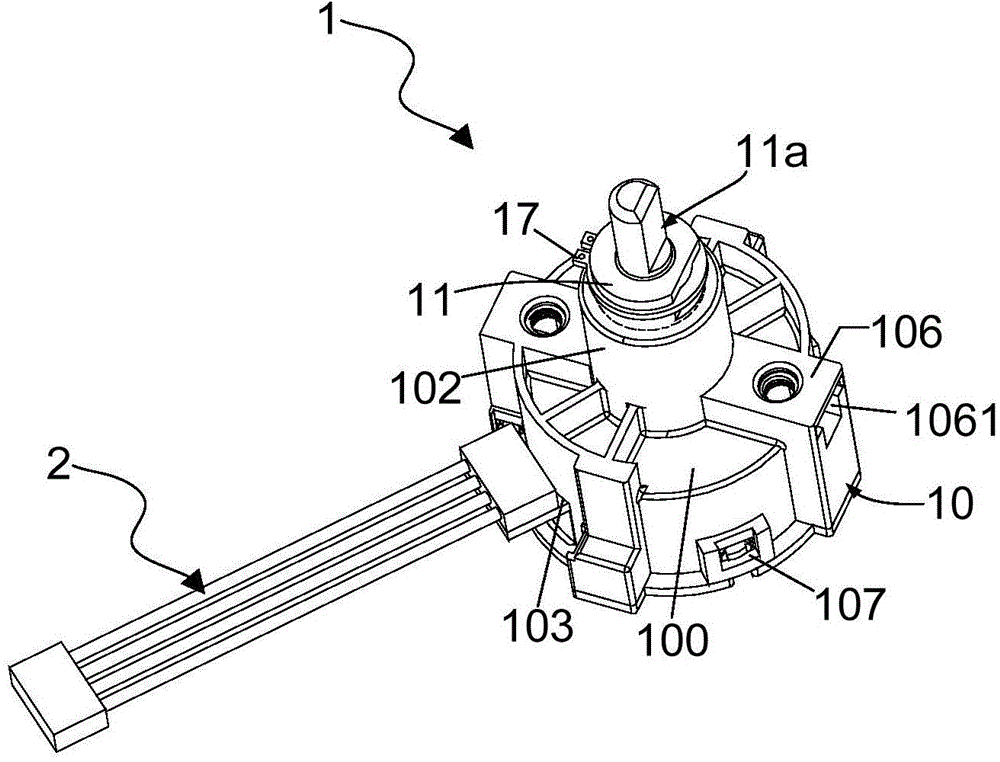

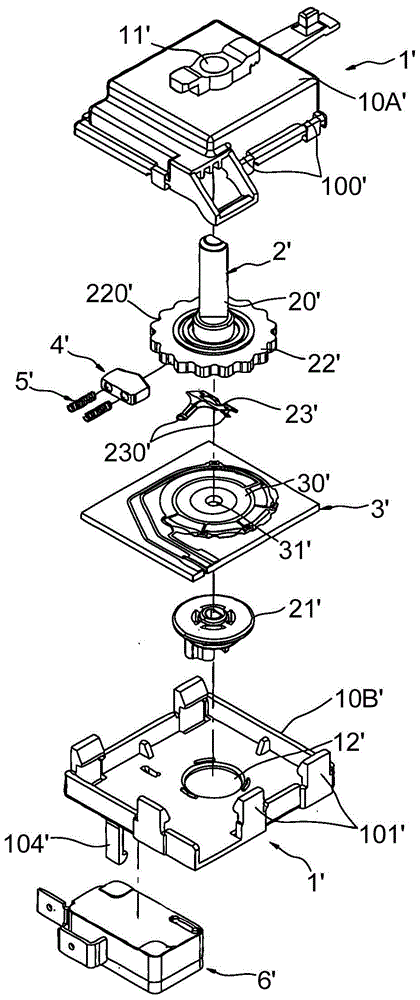

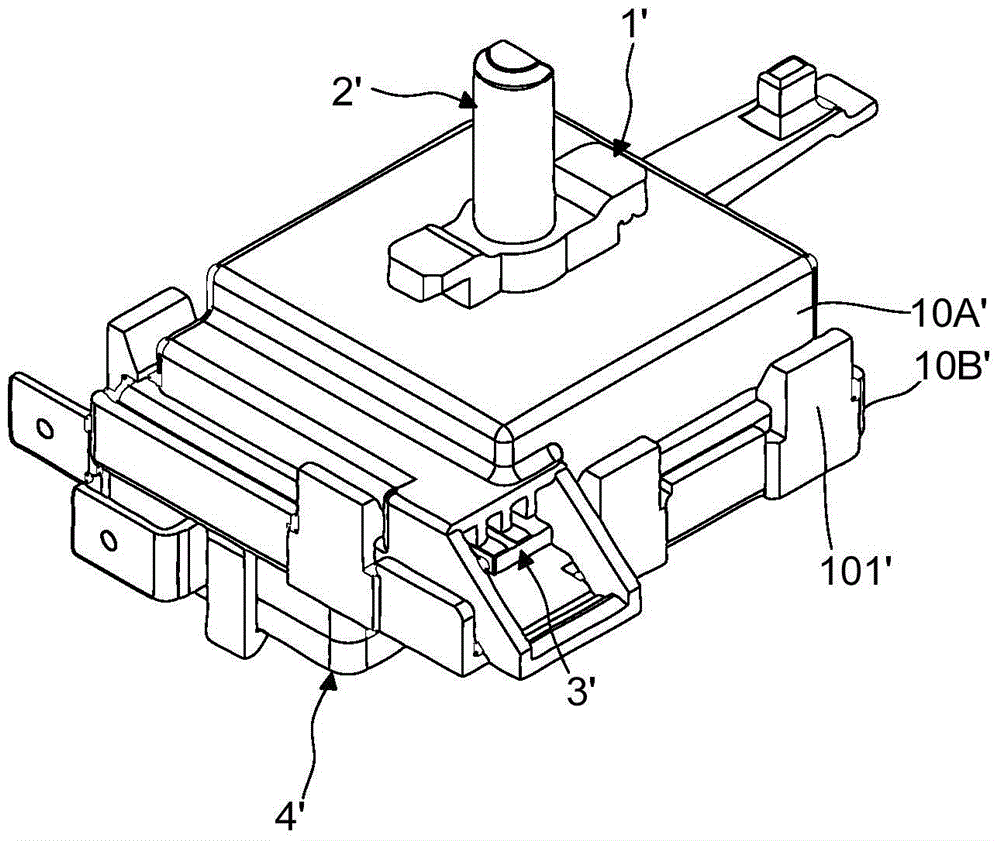

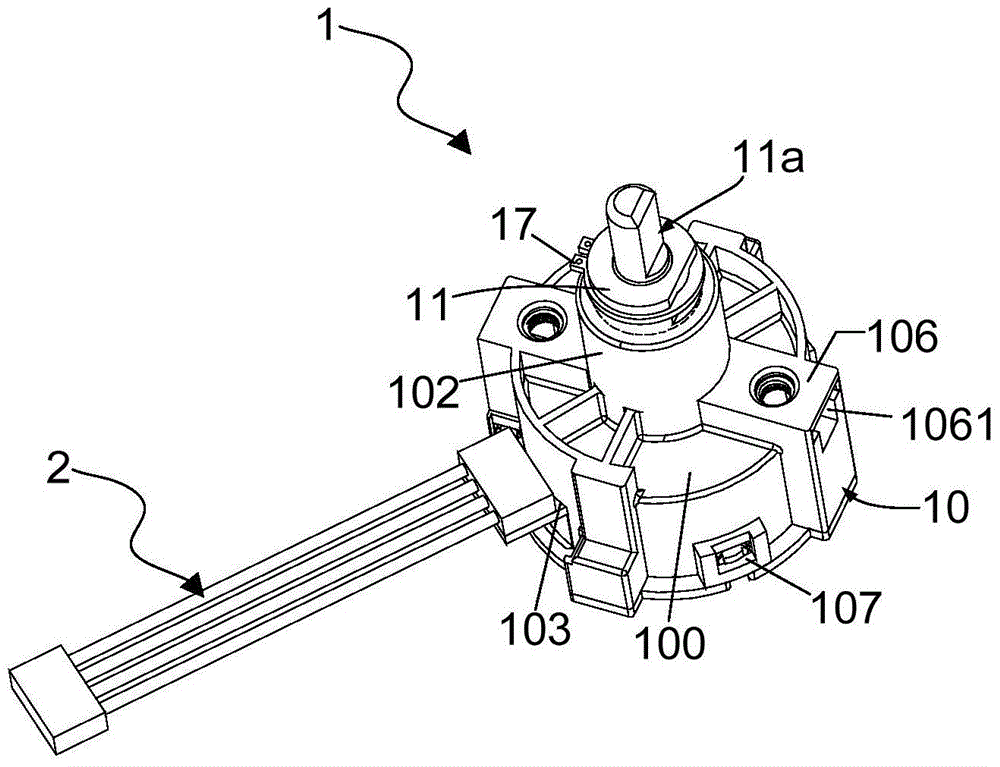

Rotary switch

The invention discloses a rotary switch in a double-shaft (optional) bidirectionally-rotatable design, up to 32 switching segments. In addition, an abutting member provided with a spring cavity is provided and used to hold and confine a compression spring therein, thus when stressed and compressed, the compression spring is avoided being bent, and the abutting member can be completely embedded in a cavity of a turnplate; smooth function switching is ensured for electric products.

Owner:SOLTEAM ELECTRONICS DONG GUAN +2

A kind of preparation method of high oil content soybean powder oil

The present invention discloses a preparation method of a high oil containing soybean powdered oil and belongs to food processing technology. The method comprises the following steps: (1) soybeans are cleaned and crushed, the crushed soybeans are sieved to obtain soybean powder, the soybean powder is mixed with water to form a mixed liquid, an alkaline protease enzyme is added into the mixed liquid to conduct enzymolysis, and the enzymolyzed mixed liquid is centrifuged to obtain a liquid phase and a solid phase; (2) an emulsifier phospholipid and a wall material maltodextrin are added into the liquid phase to conduct emulsifying treatment; and (3) the emulsified liquid is subjected to high pressure homogenization process to obtain highly stable emulsion and then the emulsion is spray-dried to obtain the high oil containing soybean powdered oil. The technology is simple, the operation is safe, and the cost is low. The natural emulsion formed in the enzymolysis of soybeans can be used as a good raw material to prepare soybean powdered oil. Then an appropriate amount of phospholipids and maltodextrin are added in the preparation method. The prepared soybean powdered oil is good in quality, high in oil amount, free of oil leakage, and has broad application prospects.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

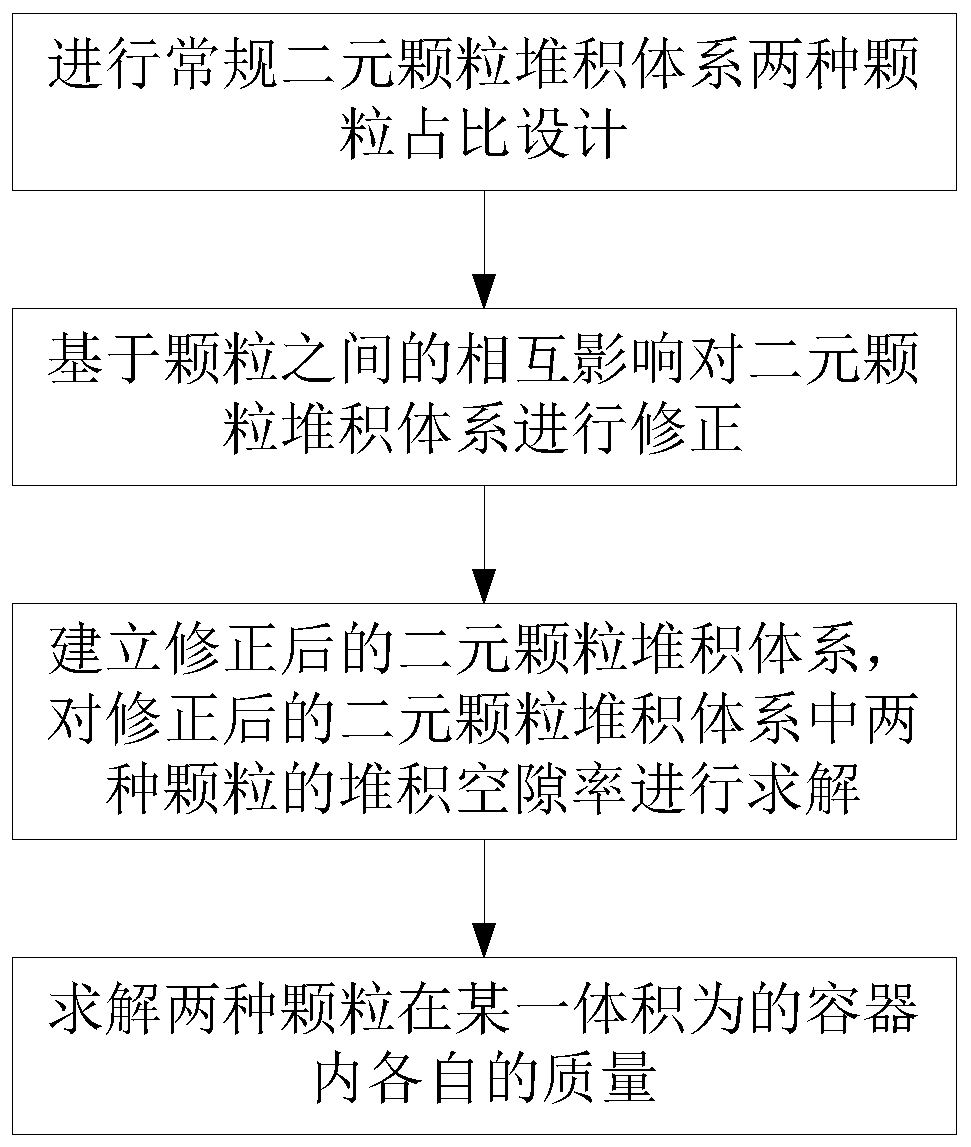

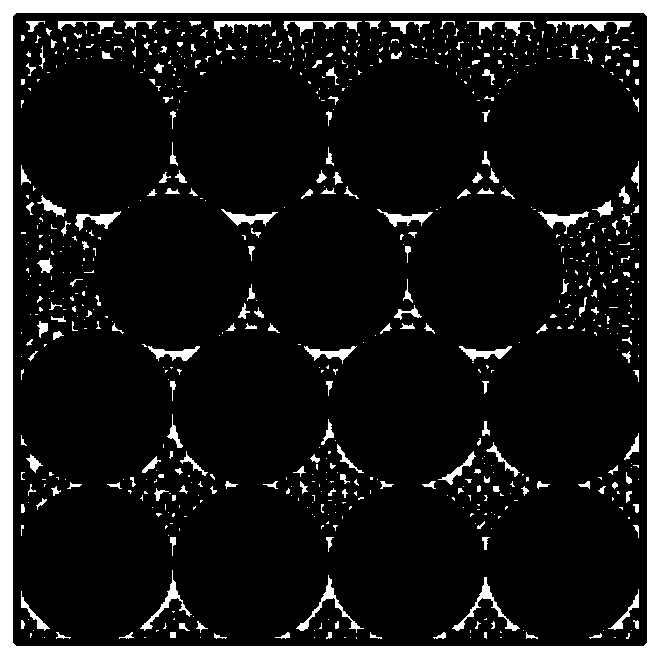

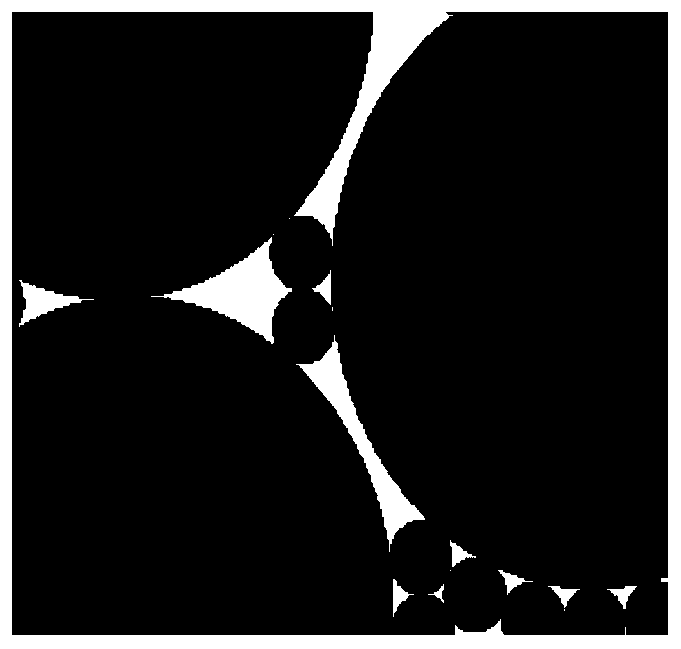

Corrected binary particle gap accumulation design method based on mutual influence among particles

ActiveCN110414177AImprove compactnessEvenly distributedSpecial data processing applicationsPorosityVoid ratio

The invention discloses a corrected binary particle gap accumulation design method based on mutual influence among particles. The method comprises the following steps: designing the proportion of twoparticles in a conventional binary particle accumulation system; correcting the binary particle accumulation system based on the mutual influence among the particles; establishing a corrected binary particle accumulation system, and solving the accumulation void ratio of two kinds of particles in the corrected binary particle accumulation system; and solving the respective mass of the two kinds ofparticles in a certain container with the volume of V. According to the method, the influence of two kinds of particles with different particle sizes on mutual space occupation in a binary particle mixed accumulation system is introduced on the basis of a binary particle gap accumulation design method of mutual influence between particles. The proportion of the two particles in the binary particle accumulation system is corrected by considering the influence of the particle size ratio of the two particles in the accumulation system. The porosity of the corrected actual binary accumulation system is reduced. The two kinds of particles can be in full contact, which are uniformly distributed and are interlocked with each other.

Owner:NORTHEASTERN UNIV

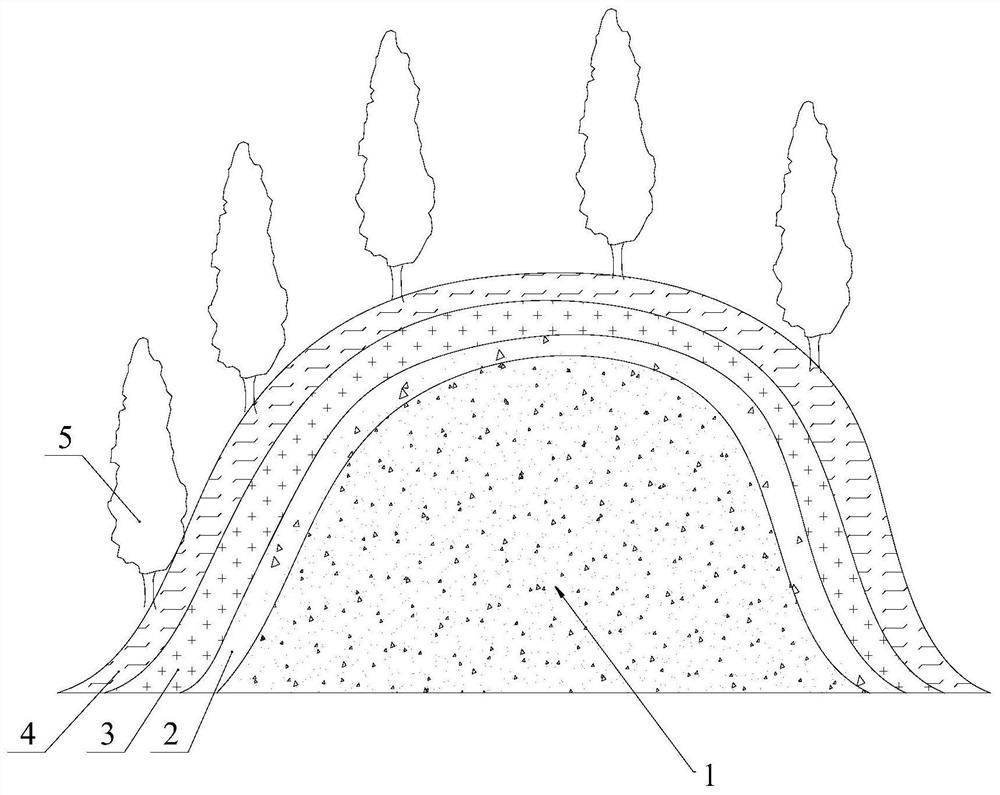

Eco-environmental treatment methods of non-ferrous metal mine waste rock yard

ActiveCN108650915BNot easy to failEasy to embedSoil-working methodsEnvironmental resource managementEcological environment

Owner:江苏绿之源生态建设有限公司

Thrombectomy device

The invention provides a thrombectomy device. The thrombectomy device comprises a first thrombectomy bracket, a delivery catheter and a tensioning guide wire, the end portion of the delivery catheteris fixedly connected to the a proximal end of the first thrombectomy bracket to drive the first thrombectomy bracket to move, the outside of the tensioning guide wire is sleeved with the delivery catheter, and the end portion, close to the first thrombectomy bracket, of the tensioning guide wire extends out of the catheter and is fixedly connected to a distal end of the first thrombectomy bracket.The invention can achieve an effective adjustment of the supporting force.

Owner:威海维心医疗设备有限公司

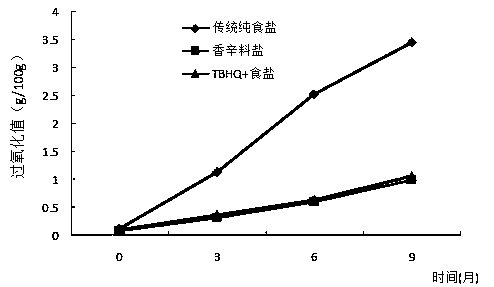

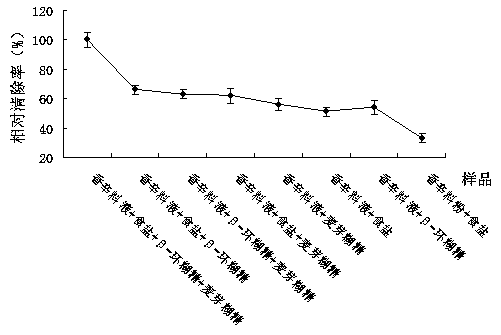

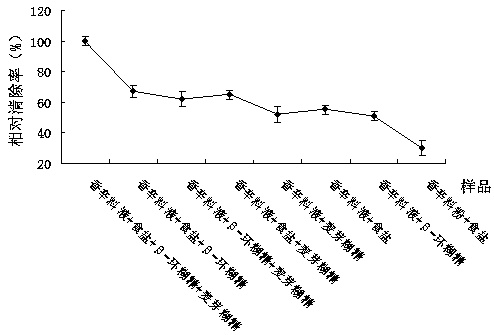

Method for preparing spice salt for inhibiting oxidation of salted preserved duck

PendingCN108850989AHigh speedEasy to achieve standardized green productionFood ingredient as antioxidantNatural extract food ingredientsFiltrationActive component

The invention relates to a method for preparing a spice salt for inhibiting the oxidation of salted preserved duck. The method comprises the following steps: 1) pulverizing a mixed spice of flos caryophylli, 20%-30% of galangal, pepper and netmeg, sieving, adding an ethanol solution, the weight of which is 10 to 30 times the weight of the spice powder, soaking at 30 to 80 DEG C for 2-5 hours, andcarrying out pressure filtration, so as to obtain spice extract liquid; 2) adding the spice extract liquid, the weight of which is 1 to 6 times the weight of salt, into the salt, separately adding beta-cyclodextrin, the weight of which accounts for 2% to 10% of the weight of the salt, and maltodextrin, the weight of which accounts for 2% to 10% of the weight of the salt, into the salt, heating forconcentrating, recovering ethanol, and heating while stirring until moisture is totally dried and the material is completely crystallized, so as to obtain a spice salt cocrystallized embedding material; and 3) crushing and sieving. The method can effectively prevent the loss of antioxidant components in spices, active components can be evenly distributed on the surface of a duck body along with the salt and the salt penetrates into the duck body fast, the surface of the duck body has no fines of spices and does not need to be cleaned, and thus the standardized green production of salted preserved duck is easy to be realized.

Owner:NANCHANG UNIV

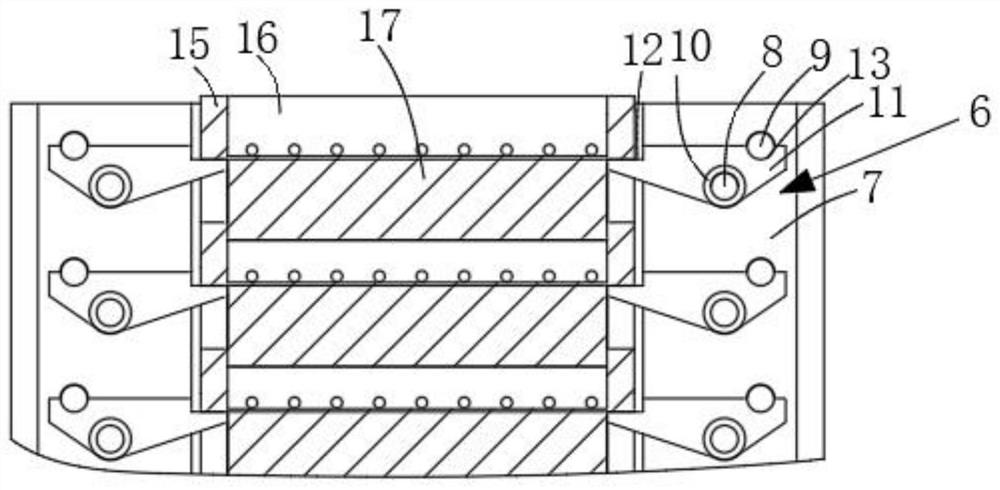

Bean curd pressing equipment

PendingCN113519782AEasy to moveImprove reliabilityFood shapingAgricultural engineeringStructural engineering

The present invention provides bean curd pressing equipment which comprises a first bottom plate (1); mounting blocks (2) are symmetrically arranged on the first bottom plate (1), a lifting air cylinder (3) is arranged between the mounting blocks (2), and a lifting plate (4) is arranged at the output end of the lifting air cylinder (3); mounting grooves (5) facing the lifting air cylinder (3) are formed in the mounting blocks (2), a plurality of mounting rod groups (6) are arranged in the mounting grooves (5) above the lifting plate (4), a placement gap (7) is reserved between every two adjacent mounting rod groups (6), and each mounting rod group (6) comprises a mounting rod (8) arranged between the groove surfaces of the two sides of the corresponding mounting groove (5). According to the invention, the bean curd forming molds are stacked, automatic pressing is conducted through the gravity generated by the device, and applicability and use convenience are high.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

Beer effervescent tablet and production method thereof

The invention discloses a beer effervescent tablet and a production method thereof, and aims to provide a beer effervescent tablet which is solid beer that is low in transport cost, long in shelf life, easy to carry, capable of producing rich carbon dioxide, simple and convenient in drinking and free from alcohol, and a production method thereof. The beer effervescent tablet comprises the following raw material components by mass percentage: 40 to 60 percent of beer powder, 15 to 30 percent of acid agent, 9 to 20 percent of alkaline agent, 5 to 12 percent of maltose, 0.1 to 0.6 percent of beer essence, 0.5 to 4 percent of binding agent, 0.1 to 3 percent of lubricant, and 0.1 to 1 percent of disintegrant. The beer effervescent tablet of the invention is simple and convenient in drinking and operation. For drinking, the effervescent tablet is placed in warm drinking water, wherein a citric acid and the alkaline agent undergo a neutralization reaction upon the contact with water to form a large amount of carbon dioxide, and because super fine silicon dioxide is added as the disintegrant, the disintegration speed is so higher that beer effervescent tablet completely dissolves in one minute after being put in the water for drinking. The solution obtained after the beer effervescent tablet dissolves is strong in beer scent, and cool and refreshing.

Owner:TIANJIN UNIV OF COMMERCE

Composite conductive paste for positive and negative electrodes of lithium ion battery and preparation method thereof

ActiveCN106229032BImprove cycle lifeIncrease energy densityCell electrodesNon-conductive material with dispersed conductive materialConductive pasteInternal resistance

The invention is applicable to the technical field of lithium ion batteries and provides a composite conductive paste for positive and negative electrodes of a lithium ion battery and a preparation method thereof. The composite conductive paste for the positive and negative electrodes of the lithium ion battery comprises the following components in parts by weight: 5.0 to 7.5 parts of carbon nanotubes, 0.3 to 0.6 parts of a dispersing agent and 90 to 95 parts of N-Methyl pyrrolidone; the carbon nanotubes are composed of large-diameter carbon nanotubes and small-diameter carbon nanotubes, wherein the diameter of each large-diameter carbon nanotube is 30 to 150 nm, and the diameter of each small-diameter carbon nanotube is 1 to 30 nm, and the diameter difference between the large-diameter carbon nanotube and the small-diameter carbon nanotube is 15 nm or more; and the weight ratio of the large-diameter carbon nanotubes to the small-diameter carbon nanotubes is (3-7) :( 7-3). The composite conductive paste for the positive and negative electrodes of the lithium ion battery provided by the invention can form a good conductive network with the active materials, and thus the internal resistance of the lithium ion battery is reduced, and the lithium ion battery can have electrochemical properties such as excellent cycle life and energy density.

Owner:SHENZHEN SSZK NEW MATERIALS CO LTD

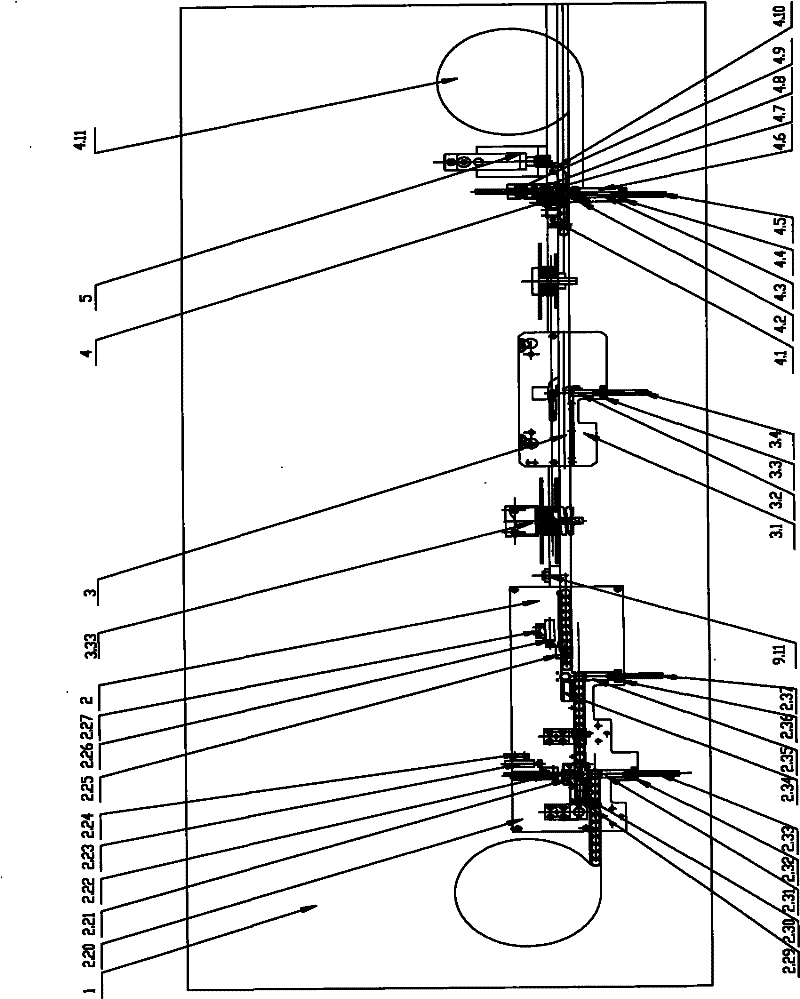

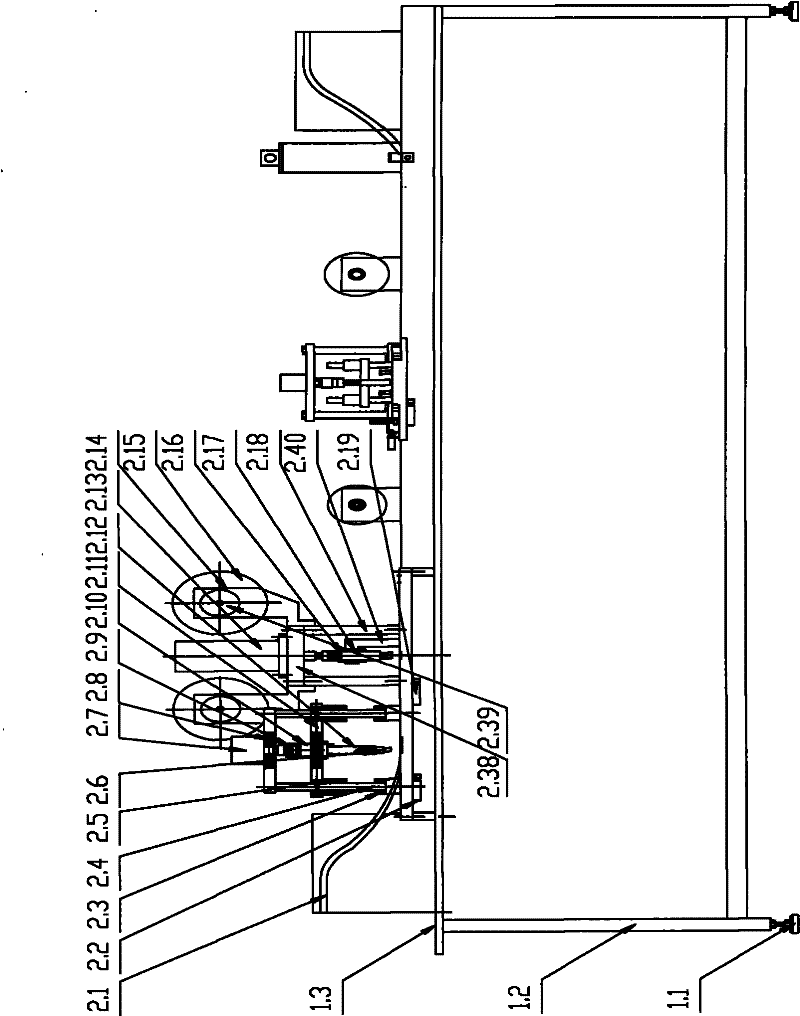

Production line for lithium fluorocarbon button cell

InactiveCN101814612BAdvanced technologyEasy to controlNon-aqueous electrolyte cellsProduction lineLithium

The invention discloses a production line for a lithium fluorocarbon button cell. The production lien is characterized by comprising a frame assembly, a lithium sheet shear-pressing mechanism, a paper cutting mechanism, an injection mechanism, a fluorocarbon feeding mechanism, an infiltration mechanism, an anode shell adding mechanism, a sealing mechanism, a main transmission mechanism, a pneumatic control system, an electric appliance control system and a control program. The production line adopts machine, electricity, gas and liquid integrated automatic technology, and can realize automation for assembling the lithium fluorocarbon button cell.

Owner:天津市五维精创自动化科技有限公司 +1

Rotary switch

The invention discloses a rotary switch in a double-shaft (optional) bidirectionally-rotatable design, up to 32 switching segments. In addition, an abutting member provided with a spring cavity is provided and used to hold and confine a compression spring therein, thus when stressed and compressed, the compression spring is avoided being bent, and the abutting member can be completely embedded in a cavity of a turnplate; smooth function switching is ensured for electric products.

Owner:SOLTEAM ELECTRONICS DONG GUAN +2

Metal parts embedding equipment for plastic products production

ActiveCN113442371BImprove connection strengthImprove efficiencyCoatingsHydraulic cylinderElectrophoreses

The invention belongs to the technical field of plastic product production, and is specifically metal parts embedding equipment for plastic product production, including: an injection molding mechanism, a molding mechanism, a pressing mechanism, a feeding mechanism, a positioning mechanism and a mouth changing mechanism. The injection molding mechanism includes a machine body, An injection molding machine for injection molding and a cooling machine for cooling; the molding mechanism includes a hydraulic cylinder one installed on the machine body for driving operations. In the present invention, the molding mechanism is used in combination with the molding mechanism and the feeding mechanism, so that the metal parts can enter between the movable mold and the fixed mold through conveying and extrusion deformation, and then perform injection molding. Compared with the prior art, it can Under the condition of controlling the depth, the metal parts are wrapped and connected, which significantly improves the connection strength between plastic and metal, and the integrated operation squeezes the surface of the metal parts, which is more convenient and quicker than electrophoresis and corrosion methods. The efficiency is high, and the connection effect is not affected, and it is convenient to popularize and use.

Owner:XINGHUA SANCHENG PRECISION FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com