Method for preparing spice salt for inhibiting oxidation of salted preserved duck

A technology of spices and salted duck, applied in food ingredients as antioxidants, chemical preservation of meat/fish, food ingredients containing natural extracts, etc., can solve the problems of effective ingredient penetration, slow duck body, and affect the appearance of salted duck products, etc. Achieve the effect of no cleaning and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A 30-mesh sieve is passed after crushing the mixed spices with a weight ratio of 30% cloves, 25% galangal, 25% prickly ash and 20% nutmeg, adding 50% (v / v) ethanol aqueous solution of 20 times the weight of the spice powder at 50 Soak at ℃ for 3 hours, press filter to obtain the spice extract, add 2 times the weight of the spice extract to the salt, and add 5% of the salt weight β-cyclodextrin and 5% maltodextrin , boiled with high-pressure steam, heated and concentrated, recovered ethanol, stirred while heating, the peripheral speed of the outer edge of the anchor stirrer blade is 0.6m / s, until the water is dry, the material is completely crystallized, and the spice salt co-crystallization is obtained. The spice salt co-crystal embedding is pulverized, passed through a 30-mesh sieve, weighed, and bagged to obtain a slag-free spice salt product that inhibits the oxidation of salted duck.

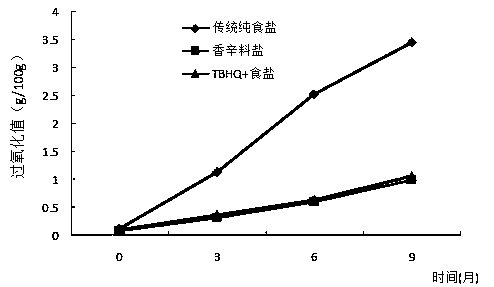

[0034] The prepared spice salt product is added in an amount of 3% of the weight ...

Embodiment 2

[0036] After crushing the mixed spices of 30% cloves, 25% ginger, 25% prickly ash and 20% nutmeg by weight, pass through a 30 mesh sieve, add 50% (v / v) aqueous ethanol solution of 20 times the weight of the spice powder at 65 Soak at ℃ for 2 hours, press filter to get the spice extract, add 3 times the weight of the spice extract to the salt, and add 5% of the salt weight β-cyclodextrin, 7.5% maltodextrin and 5% monosodium glutamate, boiled by high-pressure steam, heated and concentrated, recovered ethanol, stirred while heating, the peripheral speed of the outer edge of the anchor stirrer blade is 0.7m / s, until the water is dry, the material is completely crystallized, and the spice salt is obtained The co-crystal embedding material is crushed, passed through a 30-mesh sieve, weighed, and bagged to obtain a slag-free spice salt product that inhibits the oxidation of salted duck.

[0037] The prepared spice salt product is added in an amount of 2.7% of the weight of the bright...

Embodiment 3

[0039] After crushing the mixed spices of 30% cloves, 25% ginger, 25% prickly ash and 20% nutmeg by weight, pass through a 20 mesh sieve, add 50% (v / v) aqueous ethanol solution of 10 times the weight of the spice powder at 70 Soak at ℃ for 2 hours, after pressure filtration, add 50% (v / v) ethanol aqueous solution 10 times the weight of spice powder to the spice residue, soak at 70℃ for 2 hours, after pressure filtration, combine two extractions to obtain Spice extract, after two extractions, the active ingredients in the spices are more fully extracted, add 2 times the weight of the spice extract to the salt, and add β-cyclodextrin and salt weight 5% of the salt weight 5% maltodextrin is boiled with high-pressure steam, heated and concentrated, ethanol is recovered, stirred while heating, and the peripheral speed of the outer edge of the anchor stirrer blade is 0.6 m / s, until the water is dried, and the material is completely crystallized to obtain Spice salt co-crystal embedd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com