Low-cost hydrothermal-assisted method for preparing graphene oxide

A hydrothermal and fossil technology, applied in the field of graphene, can solve the problems of increasing the difficulty of preparation, reducing the yield, and limiting the degree of completeness of the reaction, and achieves the effects of high safety, improved yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

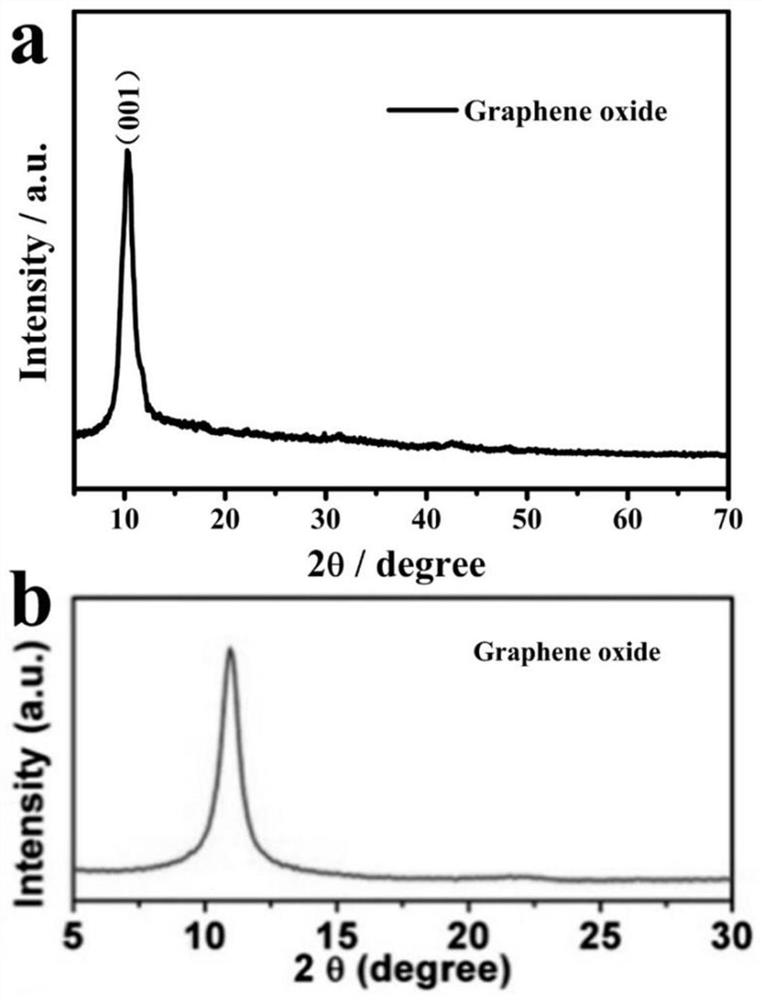

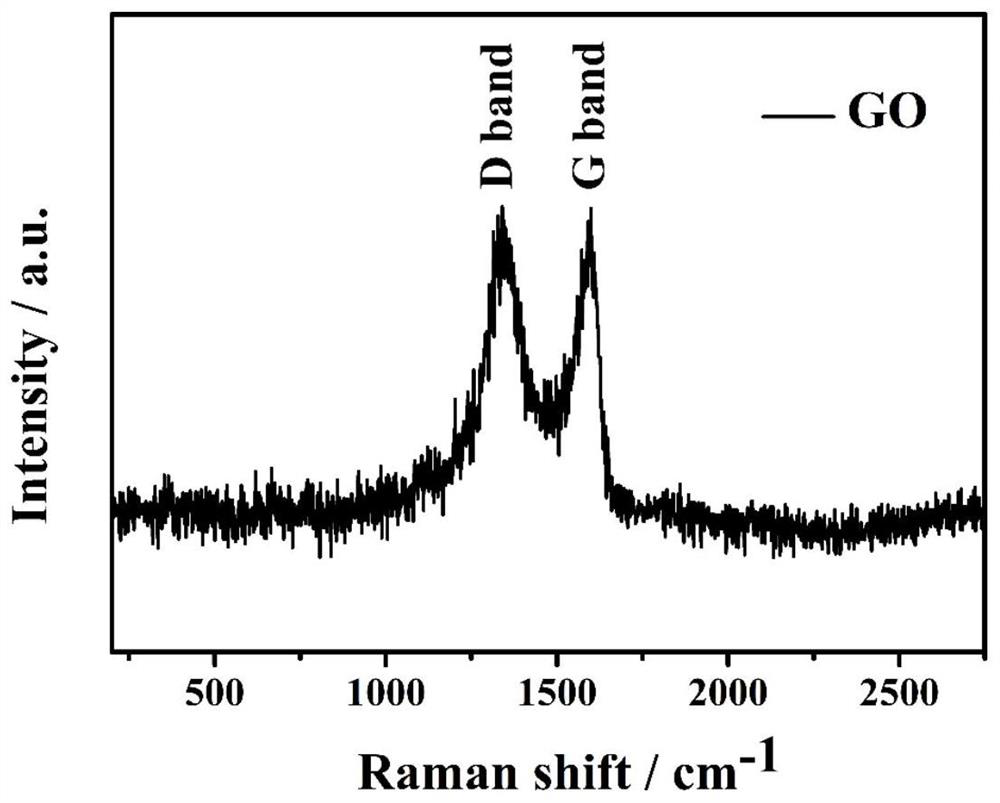

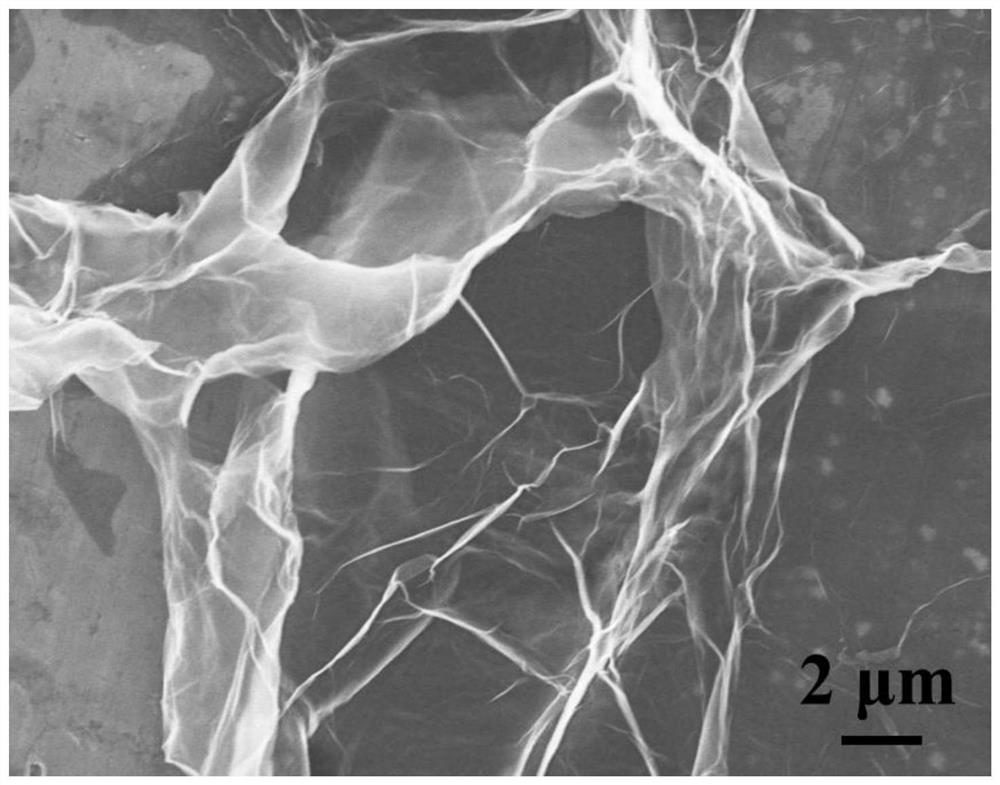

Image

Examples

Embodiment 1

[0042] A method for hydrothermally assisting the preparation of graphene oxide, comprising steps as follows:

[0043] (1) First clean and thoroughly dry the 100mL polytetrafluoroethylene reactor lining, measuring cylinder and other utensils and the concentrated sulfuric acid (H 2 SO 4 ), potassium permanganate (KMnO 4 ), expanded graphite (EG) and other raw materials are fully dried and placed in a refrigerator at a temperature of 1°C, and cooled at a constant temperature for more than 12 hours for later use.

[0044] (2) Measure 50 mL of fully cooled concentrated sulfuric acid, transfer it to a 250 mL beaker, weigh 0.1 g of expanded graphite, add it to concentrated sulfuric acid, and stir thoroughly for 10 min. Weigh 3.0g of potassium permanganate and add it to the above solution, and fully stir for 20min. The obtained mixed solution was slowly transferred to a 100 mL polytetrafluoroethylene reaction kettle, sealed in a stainless steel jacket, and placed in a refrigerator ...

Embodiment 2

[0047] A method for hydrothermally assisting the preparation of graphene oxide, comprising steps as follows:

[0048] (1) First clean and thoroughly dry the 100mL polytetrafluoroethylene reactor lining, measuring cylinder and other utensils and the concentrated sulfuric acid (H 2 SO 4 ), potassium permanganate (KMnO 4 ), expanded graphite (EG) and other raw materials are fully dried and placed in a refrigerator at a temperature of 1°C, and cooled at a constant temperature for more than 12 hours for later use.

[0049] (2) Measure 60 mL of fully cooled concentrated sulfuric acid, transfer it to a 250 mL beaker, weigh 0.5 g of expanded graphite, add it to the concentrated sulfuric acid, and fully stir for 10 min. Weigh 6.0g of potassium permanganate and add it to the above solution, and fully stir for 20min. The obtained mixed solution was slowly transferred to a 100 mL polytetrafluoroethylene reaction kettle, sealed in a stainless steel jacket, and placed in a refrigerator a...

Embodiment 3

[0052] A method for hydrothermally assisting the preparation of graphene oxide, comprising steps as follows:

[0053] (1) First clean and thoroughly dry the 100mL polytetrafluoroethylene reactor lining, measuring cylinder and other utensils and the concentrated sulfuric acid (H 2 SO 4 ), potassium permanganate (KMnO 4 ), expanded graphite (EG) and other raw materials are fully dried and placed in a refrigerator at a temperature of 1°C, and cooled at a constant temperature for more than 12 hours for later use.

[0054] (2) Measure 50 mL of fully cooled concentrated sulfuric acid, transfer it to a 250 mL beaker, weigh 0.9 g of expanded graphite, add it to the concentrated sulfuric acid, and fully stir for 10 min. (3) Weigh 9.0g of potassium permanganate and add it into the above solution, and fully stir for 20min. The obtained mixed solution was slowly transferred to a 100 mL polytetrafluoroethylene reaction kettle, sealed in a stainless steel jacket, and placed in a refriger...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com