Production method of ammonium sulfate-ammonium phosphate composite fertilizer

A technology of ammonium thiophosphate and its production method, which is applied in the direction of ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, phosphate fertilizer, etc. It can solve problems such as insoluble in water, low direct absorption efficiency of plants, complex process design, etc., and achieve solubility Good, remarkable energy-saving effect, uniform nutrient distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

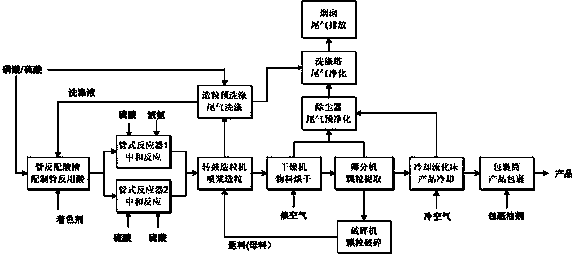

Method used

Image

Examples

Embodiment

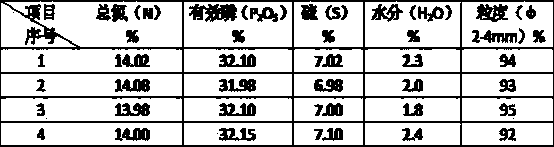

[0032] Example: N: P 2 o 5 : S=14:32:7 compound fertilizer process

[0033] In such products, the total nitrogen (N) content is ≥14.0%, and the available phosphorus (P 2 o 5 ) content ≥ 32.0%, sulfur (S) content ≥ 7.0%.

[0034] Taking 1 ton of product as the measurement, each ton of ammonium sulfate phosphate product contains 140kg of nitrogen (N), phosphorus pentoxide (P 2 o 5 ) 320kg, sulfur (S) 70kg, then the purity is 99.6% (as NH 3 In terms of liquid ammonia, the concentration is 47% (in P 2 o 5 In terms of) phosphoric acid, concentration 98% (as H 2 SO 4 Calculated by using concentrated sulfuric acid as raw material and resource yield of 98%, the unit consumption of liquid ammonia (NH 3 )174.17kg, concentrated phosphoric acid (47%P 2 o 5 ) 958.75kg, concentrated sulfuric acid (98%H 2 SO 4 ) 223.21kg.

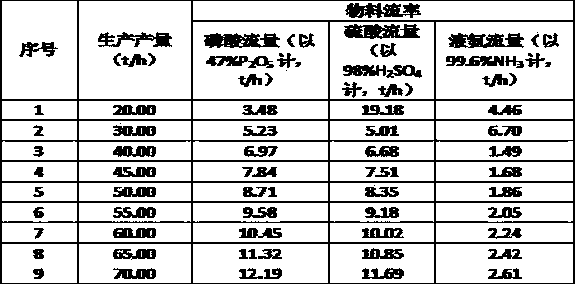

[0035] During the production process, according to the production load of the system, feed materials in proportion. The mass flow of concentrated phos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com