A kind of preparation method of high oil content soybean powder oil

A powder oil and soybean powder technology, which is applied in the field of preparation of high-oil soybean powder oil, can solve the problems of poor film-forming property of maltodextrin, poor self-repair ability of maltodextrin, and non-spherical product particles, etc. , to achieve the effects of reducing preparation costs, reliable theoretical support, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

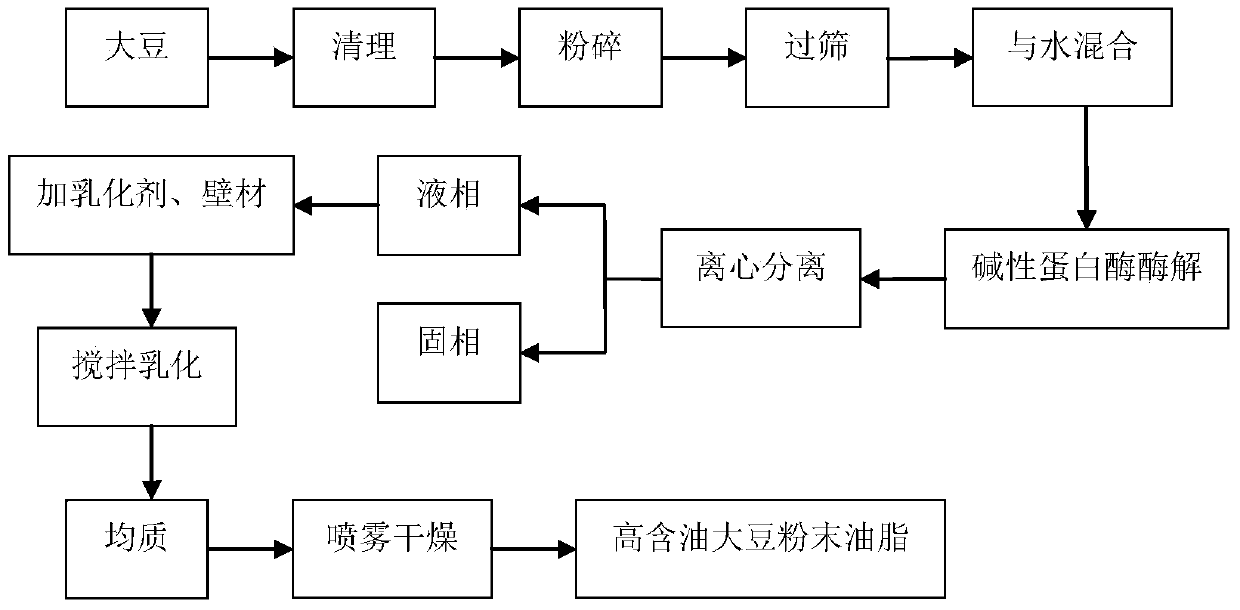

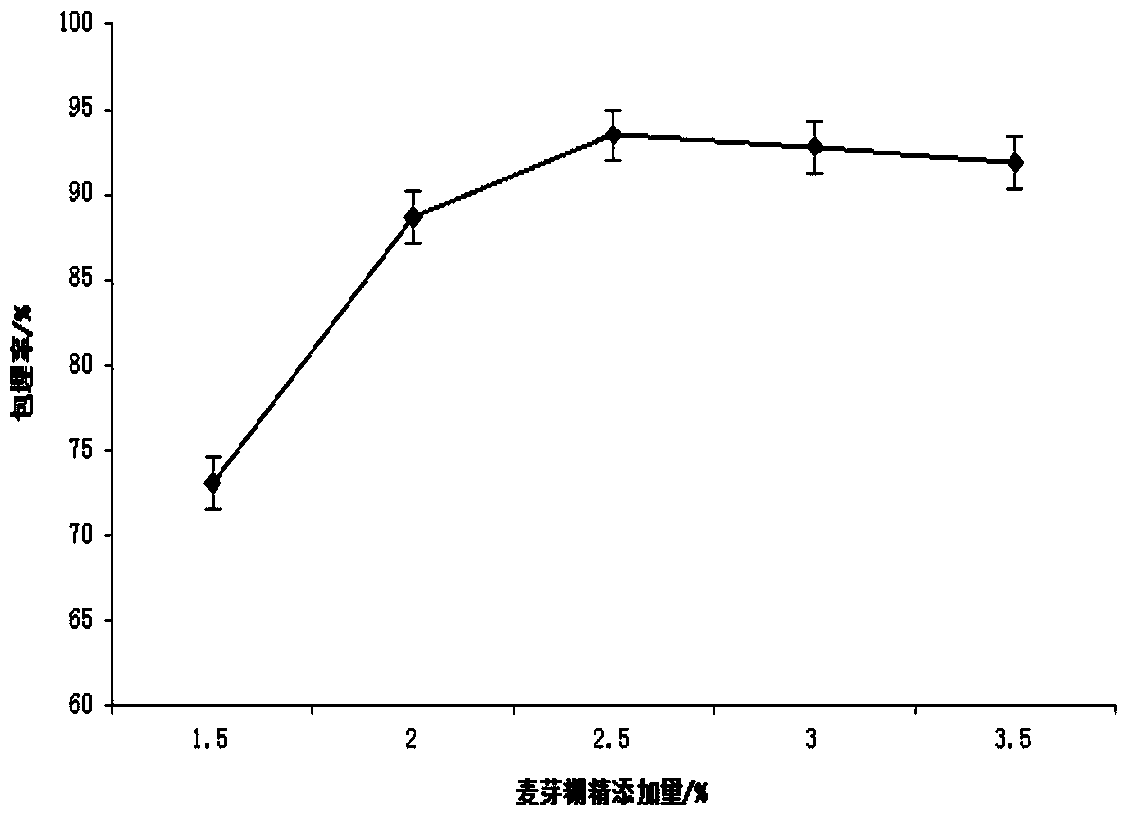

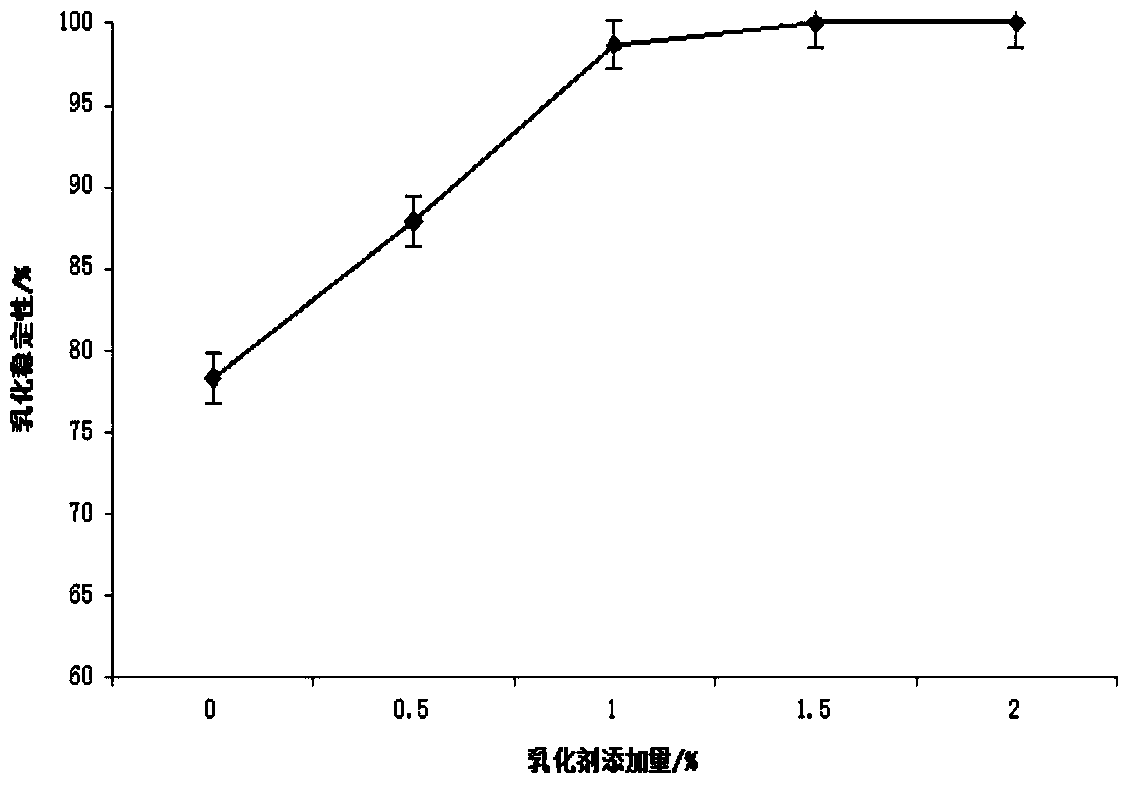

[0020] A method for preparing high-oil-containing soybean powder oil, the method comprising the following steps: (1) cleaning and pulverizing soybeans and passing them through a 60-mesh sieve to obtain soybean powder, mixing soybean powder with water to form a mixed liquid, adjusting the temperature and pH of the mixed liquid, Add Alcalase alkaline protease to the mixed solution for enzymolysis, the added amount of the enzyme is 2% of the mass of the mixed solution, the liquid-material ratio is 7:1mL / g, the enzymolysis temperature is 55°C, and the enzymolysis time is 3h, The pH of the enzymolysis is 9.26, and after the enzymolysis, a horizontal centrifuge is used to centrifuge to obtain a liquid phase and a solid phase; (2) adding emulsifier phospholipids and wall material maltodextrin to the liquid phase, the amount of phospholipids added is The mass of the phase is 0.5-2.5%, and the amount of maltodextrin added is 1.5-3.5% of the mass of the liquid phase, and then emulsificat...

Embodiment

[0024] 1 Materials and methods

[0025] 1.1 Materials and Instruments

[0026] Soybean: Soybean Research Institute of Northeast Agricultural University; Alcalase alkaline protease: sales agent of Beijing Gao Ruisen Technology Co., Ltd.; soybean lecithin: Beijing Suolaibao Technology Co., Ltd.; maltodextrin: Beijing Suolaibao Technology Co., Ltd.; Hydrochloric acid, petroleum ether (30-60 boiling range), chloroform, methanol, etc. are analytically pure.

[0027] High-speed universal pulverizer: Shanghai Qiqian Electronic Technology Co., Ltd.; sample sieve: Xi'an Yachuang Electronic Technology Co., Ltd.; FA2004 electronic balance: Tianjin Tianping Instrument Co., Ltd.; digital display stirring water bath: Changzhou Saipu Experimental Instrument Factory; GL -21M high-speed refrigerated centrifuge: Anhui Zhongke Zhongjia Scientific Instrument Co., Ltd.; SC-3614 low-speed centrifuge: Anhui Zhongke Zhongjia Scientific Instrument Co., Ltd.; CK96-A fast mixer: Jiangyan Medical Machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com