Method for reinforcing composite vacuum prepressing soft soil foundation

A soft soil foundation and vacuum technology, which is applied in the field of soft soil foundation reinforcement and large-area deep soft soil foundation reinforcement. The effect of preloading time, increasing permeability coefficient, and increasing tamping energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

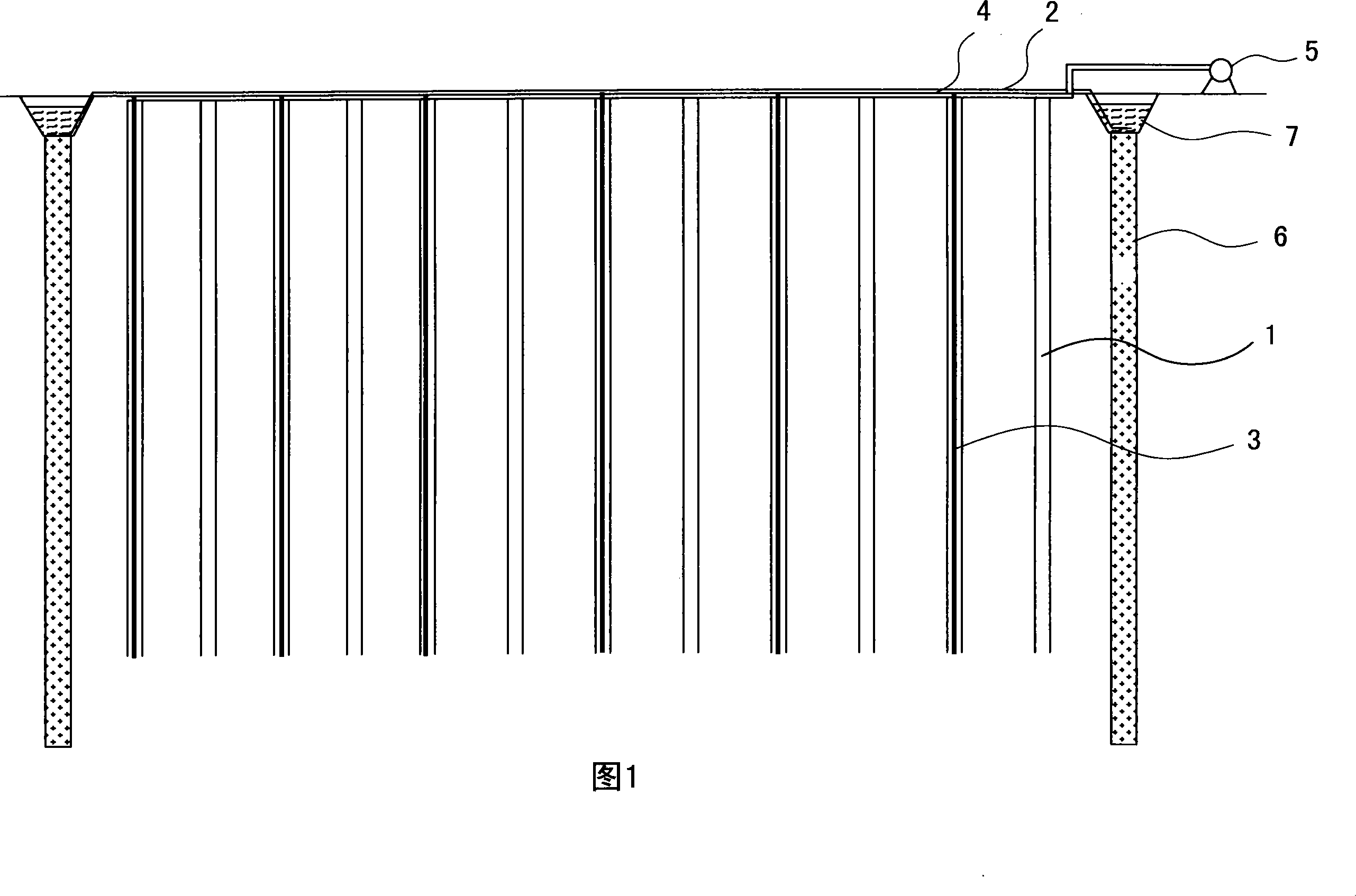

[0040] Embodiment 1: Referring to Fig. 1, a composite vacuum preloading soft soil foundation reinforcement method, the method includes vacuum preloading dewatering and electroosmotic dewatering two parts, the construction steps are as follows:

[0041] a) Leveling the site and setting up a site drainage system; including a horizontal drainage system and a vertical drainage system, the horizontal drainage system is made up of drainage blind ditches, horizontal vacuum pipes 4 and sump wells, and the vertical drainage system is composed of plastic drainage boards and positive Negative electrode 2 composition.

[0042] Insert plastic drainage boards 1 on the site to be treated. The minimum distance between the plastic drainage boards is 1m×1m, and they are arranged in a plum blossom shape. High geotextiles ensure the smooth drainage of the vacuum system; insert positive and negative electrodes, which require good electrical conductivity, such as steel bars or aluminum rods or copp...

Embodiment 2

[0050] Embodiment 2: A kind of composite vacuum preloading soft ground reinforcement method, this method comprises vacuum preloading dewatering and electroosmotic dewatering two parts, and its construction steps are as follows:

[0051] a) Leveling the site and establishing a site drainage system; including a horizontal drainage system and a vertical drainage system. electrode composition.

[0052] Insert plastic drainage boards on the treated site, the minimum spacing of plastic drainage boards is 1m×1m, and they are arranged in a plum blossom shape. Plastic drainage boards must use high-performance plastic drainage boards to ensure the mechanical strength required for smooth vacuum. The filter membrane adopts high tensile strength. Geotextiles to ensure the smooth drainage of the vacuum system; insert positive and negative electrodes, which require good electrical conductivity, such as aluminum rods or copper rods, etc., and the depth and spacing are the same as plastic drai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com