Modified transformer oil, preparation method and application

A transformer oil and modification technology, applied in the petroleum industry, lubricating composition and other directions, can solve the problems of low viscosity of transformer oil, low thermal conductivity, limited local electric field distortion, etc., to improve thermal conductivity, improve breakdown resistance, The effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0096] A preparation method for graphene derivative lamellar modified transformer oil, comprising the steps of:

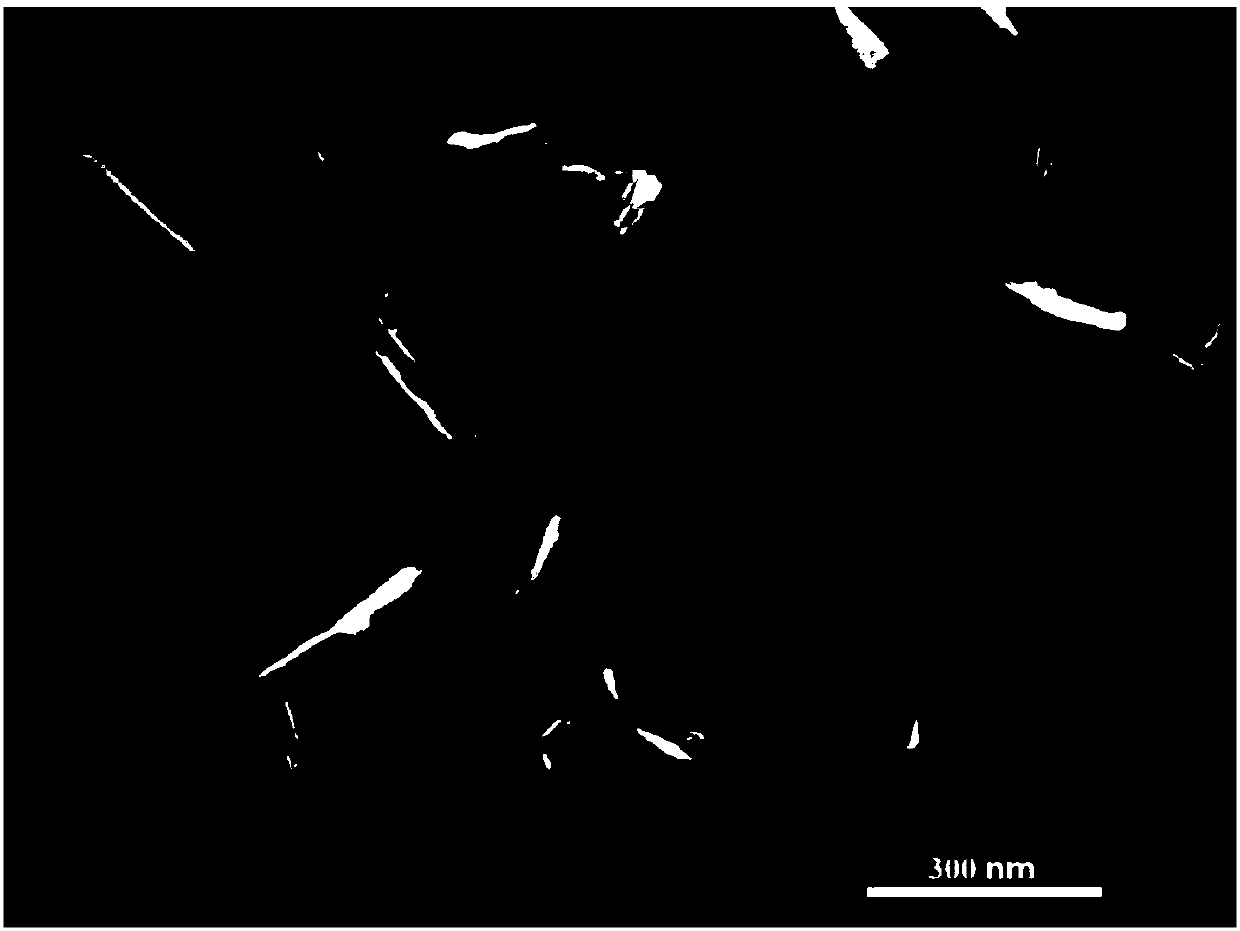

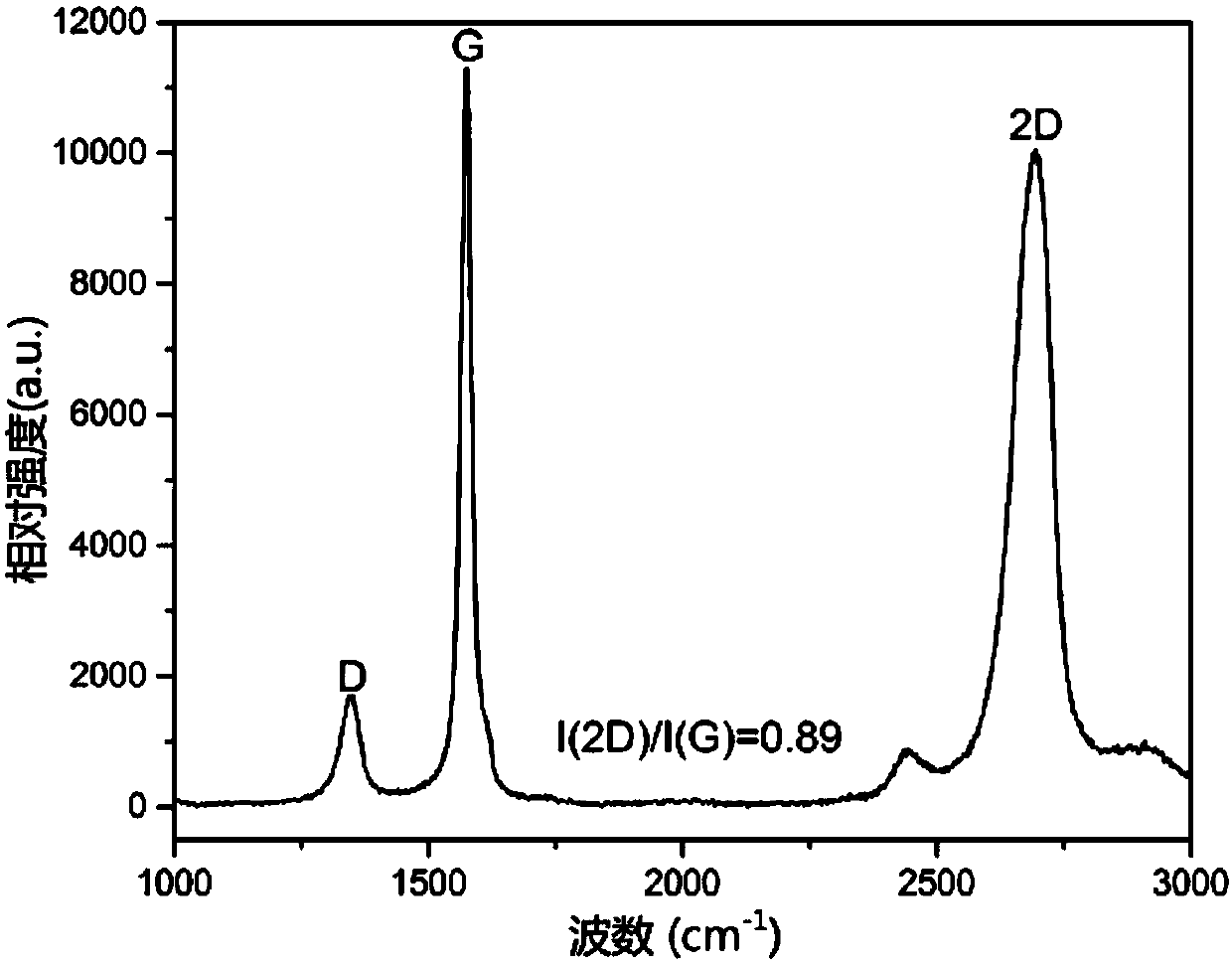

[0097] (1) Use graphite paper as the positive and negative poles of the electrochemical reaction, use 0.5mol / L dodecylbenzyl ammonium bromide solution as the electrolyte, pass through a direct current of 0.7A, and conduct electrolysis on the graphite material at 30°C Chemical peeling; the electrochemical peeling product is filtered, the filter cake is dispersed with acetone, the upper suspension is taken to filter, and dried to obtain graphene derivative sheets; the graphene derivative sheets are observed by scanning electron microscopy (such as figure 1 ), found that the sheet diameter of its two-dimensional nanosheets was between 200nm and 350nm; the graphene derivative sheets were subjected to Raman scanning (such as figure 2 ), found that its thickness is about 10nm;

[0098] (2) Mix the graphene derivative sheets and oleic acid amide obtained in step (1) wit...

Embodiment 4

[0104] The difference from Example 2 is that the base oil used is 10# transformer oil.

Embodiment 5

[0106] The difference from Example 2 is that the base oil used is 45# transformer oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com