Capacitance sensor

A capacitive sensor and sensor technology, which is applied to the liquid level indicator for physical variable measurement, etc., can solve the problems of increasing the difficulty of sensor calibration and calibration, the large difference in the quality of the measured liquid, and the difficulty of sensor calibration and calibration, and achieves a compact structure. , the structure is simple, the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

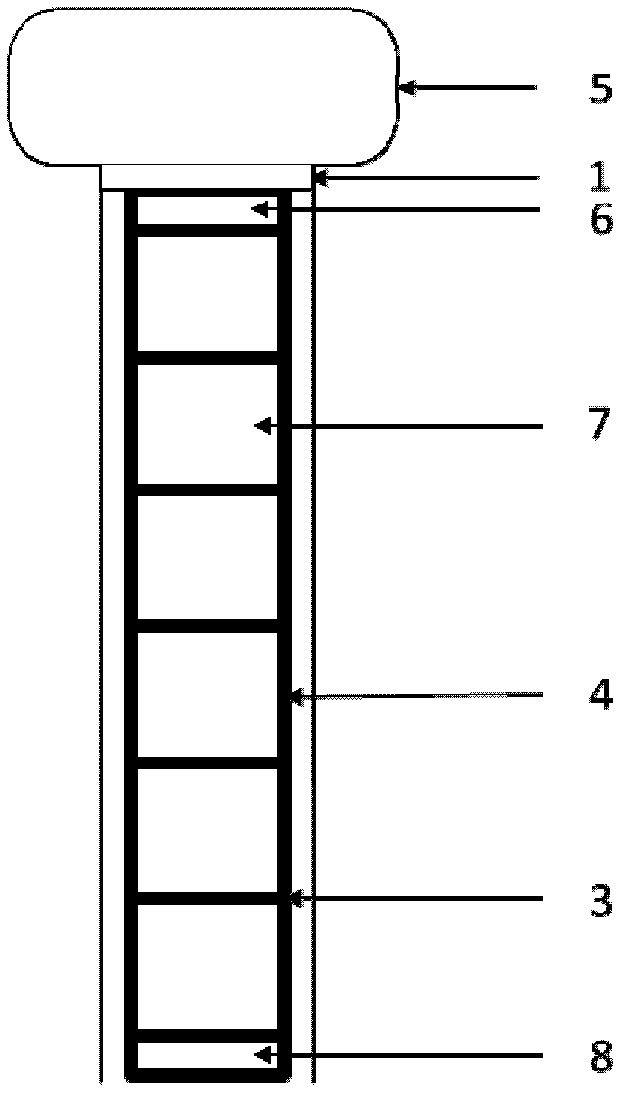

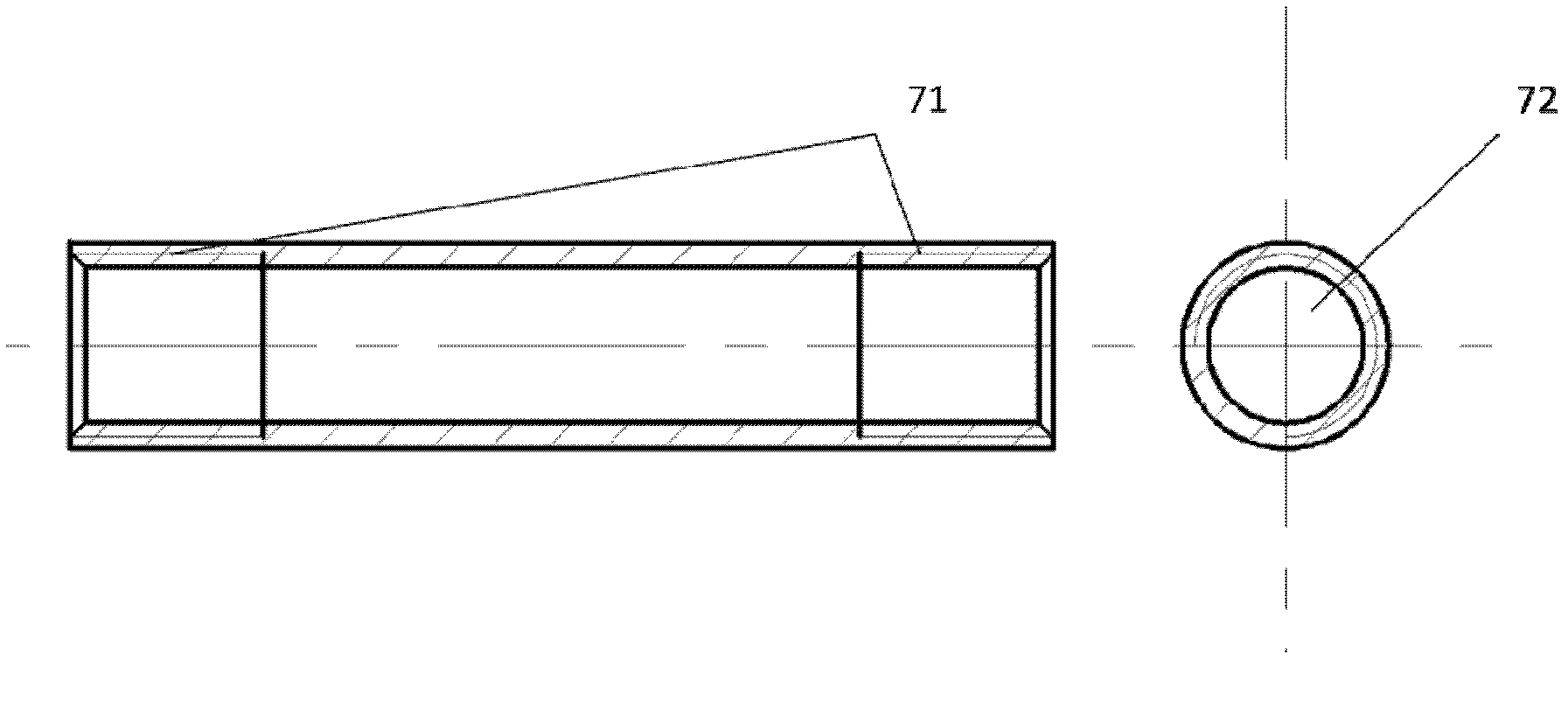

[0028] like figure 1 As shown, the capacitive sensor of the present invention includes sensor head 5, external electrode 1, top compensation electrode 6, six-segment measurement electrode 7, and bottom compensation electrode 8 from top to bottom. The individual electrodes are connected by connecting pieces 3 made of insulating material, and there is a layer of insulating material 4 outside the entire inner electrode. The sensor capacitance will vary with the liquid level between the inner and outer electrodes. The measurement circuit obtains the liquid level value by detecting the variation of the capacitance value.

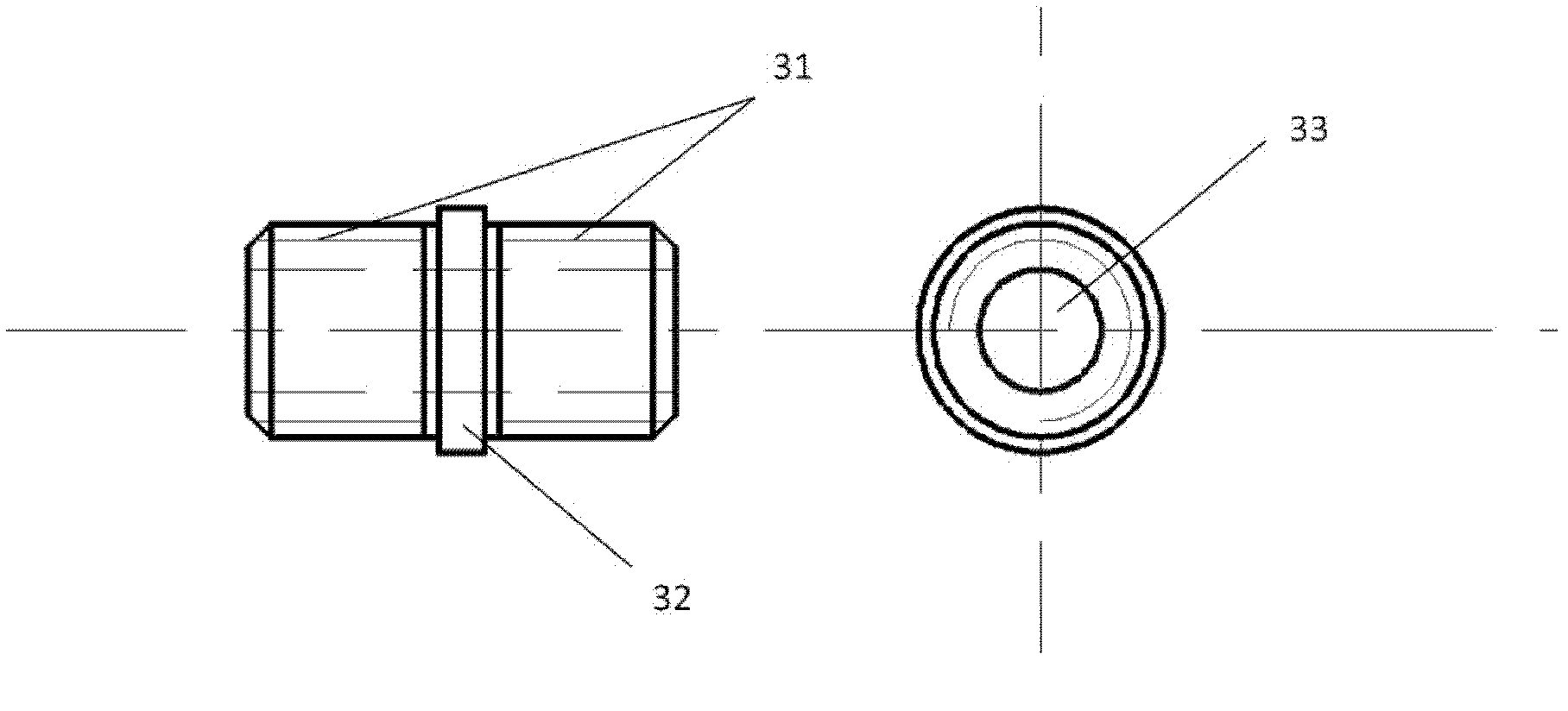

[0029] like figure 2 Shown is the front view and left view of the connector 3. The two ends of the connector 3 are external threads 31 for connecting with the electrodes of the internal electrodes. The protruding cylindrical part 32 in the middle is used for insulation of two adjacent electrodes, and its outer diameter is equal to that of the inner electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com