Automobile rubber sealing strip and preparation method thereof

A rubber sealing strip and automobile technology, applied in the field of automobile rubber parts, can solve the problems of poor compatibility and slow vulcanization speed, and achieve the effects of simple process, reduced energy consumption, and satisfactory heat aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

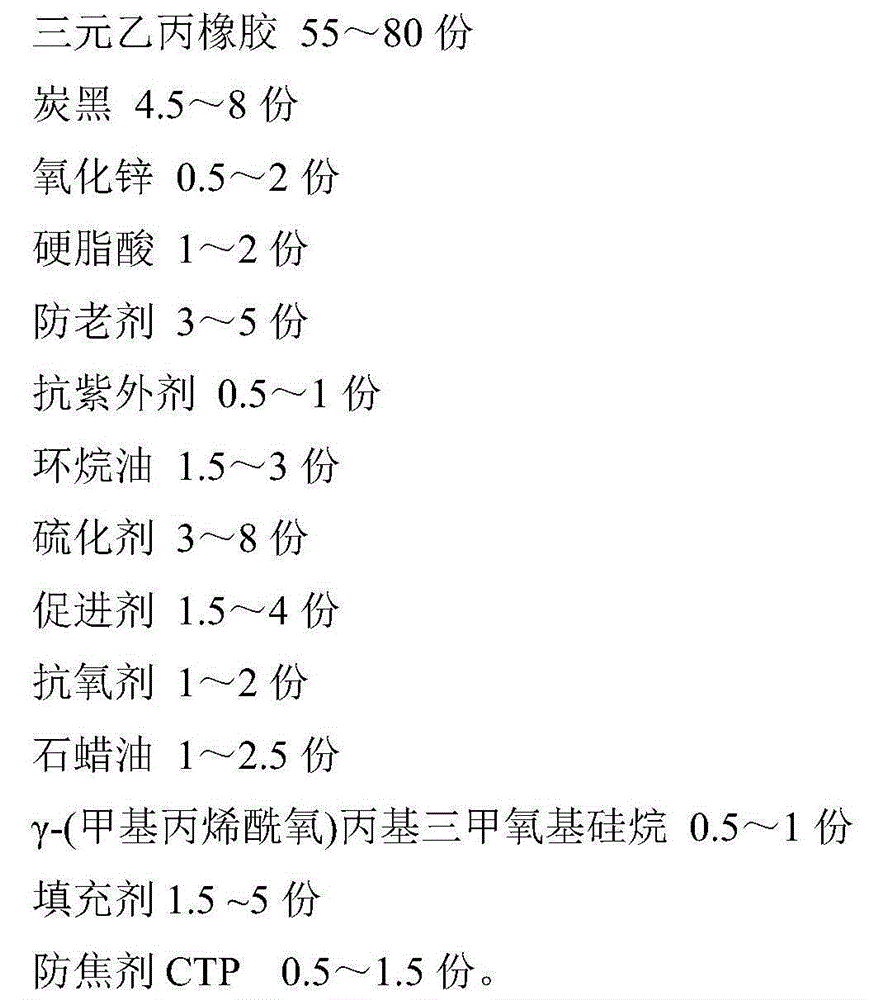

[0034] A rubber sealing strip for automobiles, consisting of the following components in parts by weight:

[0035] 55 parts of EPDM rubber, 8 parts of carbon black, 2 parts of zinc oxide, 2 parts of stearic acid, 5 parts of anti-aging agent 4010NA, 1 part of anti-ultraviolet agent, 3 parts of naphthenic oil, N, N'- m-phenylene bis 8 parts of maleimide, 4 parts of 2-mercaptobenzothiazole, 2 parts of dilauryl thiodipropionate, 2.5 parts of paraffin oil, γ-(methacryloyloxy)propyltrimethoxysilane 1 part, 5 parts of calcium carbonate, 1.5 parts of anti-scorch agent CTP.

[0036] Add the above components into the internal mixer for mixing, and the obtained mixed rubber is then tested for hardness, tensile strength, and elongation at break. Among them, the hardness of the mixed rubber reaches 73 degrees, and the tensile strength reaches 8.5Mpa. , the elongation at break reaches 320%;

[0037] Put the above-mentioned compounded rubber into a mold for thermal kneading and molding, an...

Embodiment 2

[0039] A rubber sealing strip for automobiles, consisting of the following components in parts by weight:

[0040] 60 parts of EPDM rubber, 8 parts of carbon black, 2 parts of zinc oxide, 2 parts of stearic acid, 40204 parts of anti-aging agent, 1 part of anti-ultraviolet agent, 2 parts of naphthenic oil, N-tert-butyl-2-benzene 7 parts of thiazole sulfenamide, 4 parts of zinc dimethyl dithiocarbamate, 2 parts of α-tocopherol, 2 parts of paraffin oil, 1 part of γ-(methacryloyloxy)propyl trimethoxysilane, 4 parts of calcium carbonate, 1 part of anti-scorch agent CTP.

[0041] Add the above components into the internal mixer for mixing, and the obtained mixed rubber is then tested for hardness, tensile strength, and elongation at break. The hardness of the mixed rubber reaches 77 degrees, and the tensile strength reaches 9Mpa. The elongation at break reaches 430%;

[0042] Put the above-mentioned compounded rubber in a mold for heat kneading and molding, and then place the mold...

Embodiment 3

[0044] A rubber sealing strip for automobiles, consisting of the following components in parts by weight:

[0045] 65 parts of EPDM rubber, 8 parts of carbon black, 2 parts of zinc oxide, 1.5 parts of stearic acid, 3 parts of anti-aging agent NB, 0.5 parts of anti-ultraviolet agent, 3 parts of naphthenic oil, N-tert-butyl-2-benzene 6 parts of thiazole sulfenamide, 2 parts of tellurium diethyldithiocarbamate, 2 parts of α-tocopherol, 2 parts of paraffin oil, 0.5 part of γ-(methacryloyloxy)propyltrimethoxysilane, 3 parts of light alumina, 1.5 parts of anti-scorch agent CTP.

[0046] Add the above components into the internal mixer for mixing, and the obtained mixed rubber is then tested for hardness, tensile strength, and elongation at break. The hardness of the mixed rubber reaches 75 degrees, and the tensile strength reaches 8.8Mpa. , the elongation at break reaches 450%;

[0047] Put the above-mentioned compounded rubber into a mold for thermal kneading and molding, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com