Multi-elastomer material suspension for vehicle

A multi-elastic, bulk material technology, applied in power plants, vehicle components, jet propulsion devices, etc., can solve the problems of poor main spring fatigue performance, poor adjustability, high price, and achieve improved adjustability, improved cushioning performance and The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

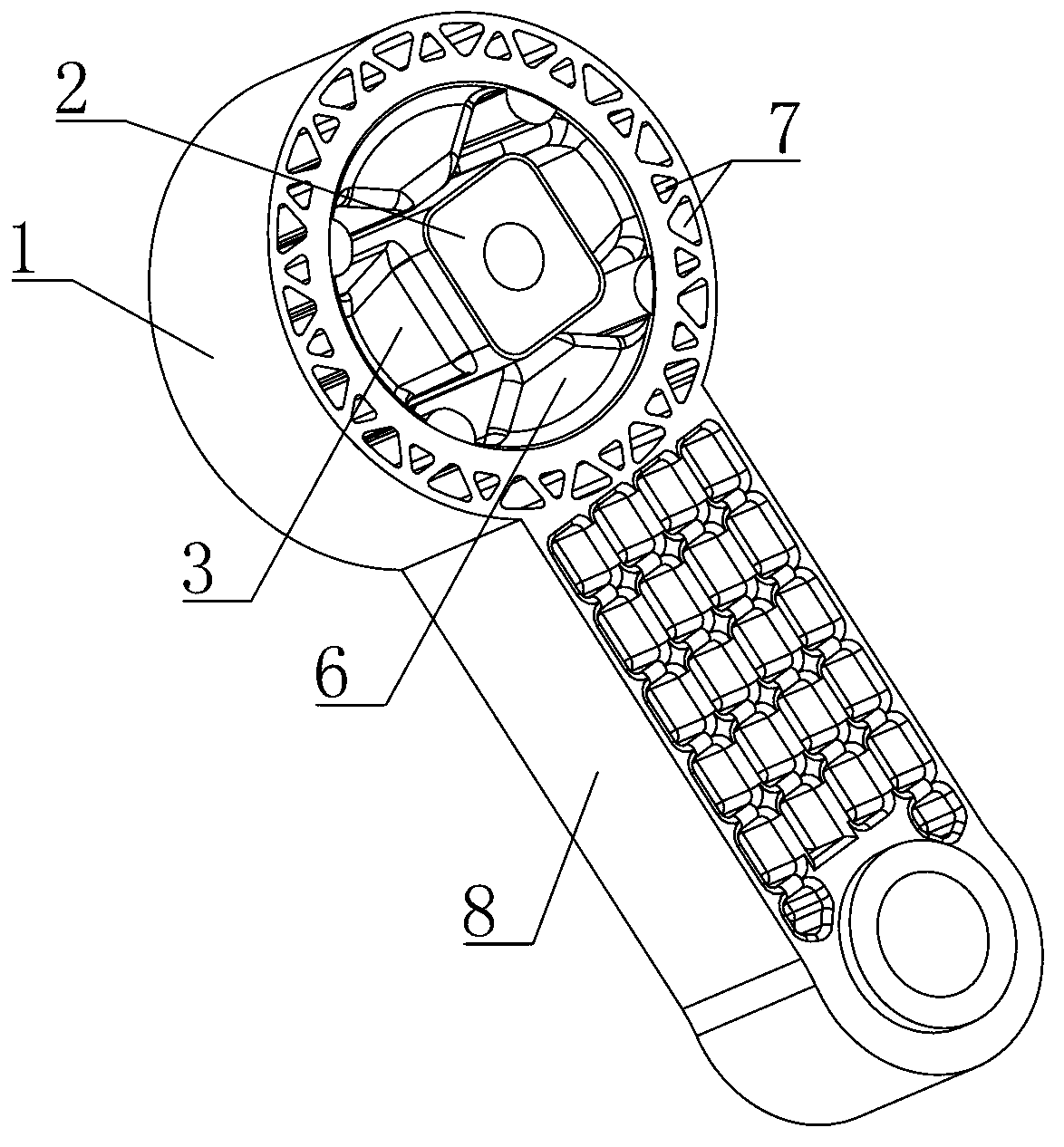

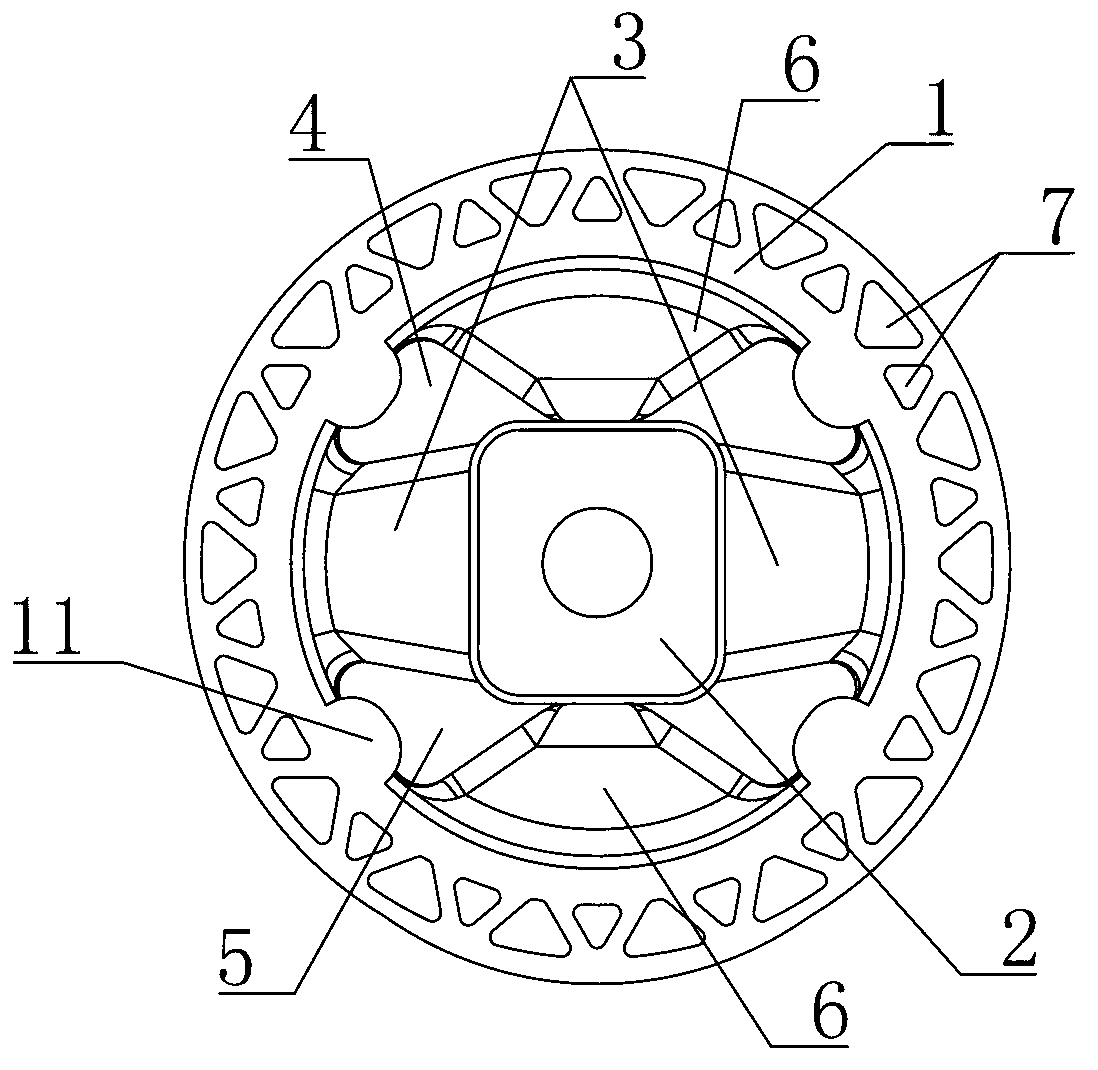

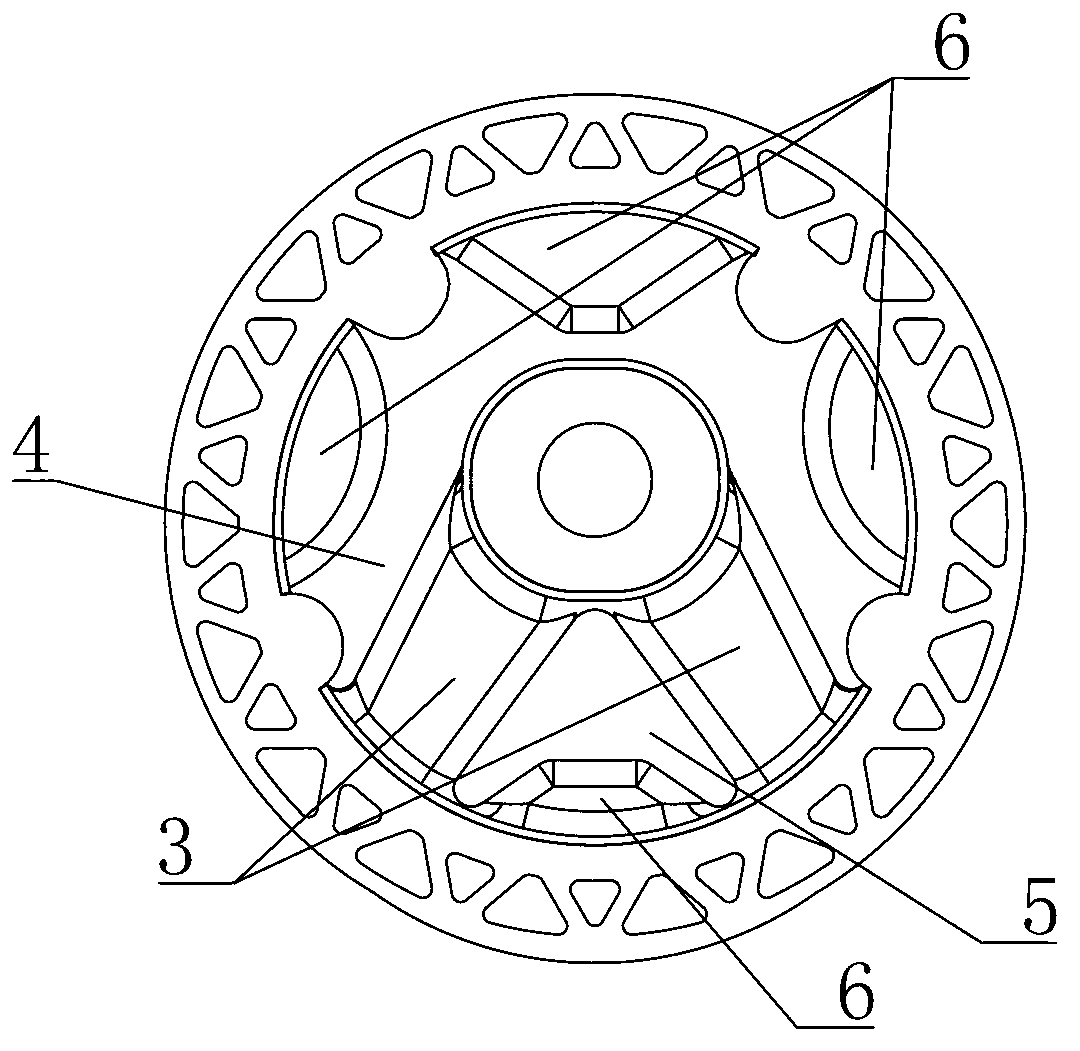

[0019] Embodiment 1: A multi-elastomer material suspension for vehicles, including an outer tube 1, an inner tube 2 and a main spring 3, one end of the main spring 3 is vulcanized with the inner tube 2, and the other end of the main spring 3 is connected with the outer tube 1 Phase vulcanization, the inner tube 2 and the main spring 3 separate the outer tube 1 into a first area 4 and a second area 5, and there are two impact blocks 6 vulcanized on the outer tube 1, one is set in the first area 4, and the other is set In the second area 5, the impact block 6 is interference-fitted with the inner tube 2, and a group of reinforcing ribs 7 are axially arranged on the outer tube 1, and the reinforcing ribs 7 are in the shape of a triangle. The positioning bump 11, the outer wall of the outer tube 1 is integrally connected with a mounting bracket 8, the main spring 3 is made of natural rubber, the bumper 6 is made of EPDM rubber or silica gel with good heat resistance, and the outer ...

Embodiment 2

[0020] Embodiment 2: A multi-elastomer material suspension for vehicles, including an outer tube 1, an inner tube 2 and a main spring 3, one end of the main spring 3 is vulcanized with the inner tube 2, and the other end of the main spring 3 is connected with the outer tube 1 Phase vulcanization, the inner tube 2 and the main spring 3 divide the outer tube 1 into a first area 4 and a second area 5, and there are four impact blocks 6 vulcanized on the outer tube 1, three are set in the first area 4, and one is set In the second area 5, a group of reinforcing ribs 7 are arranged axially on the outer tube 1, and the reinforcing ribs 7 are in a triangular shape. There is a mounting bracket 8 integrally connected, the main spring 3 is made of natural rubber, the bumper 6 is made of EPDM rubber or silica gel with good heat resistance, the outer tube 1 is made of nylon or aluminum alloy, and the mounting bracket 8 The material is the same as that of the outer tube 1 .

Embodiment 3

[0021] Embodiment 3: The other parts are the same as in Embodiment 1, the difference is that the bumper 6 is made of butadiene rubber with good wear resistance, and besides, the bumper 6 can also be made of thermoplastic elastic rubber with good wear resistance. Body polyurethane foam molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com