Low-moisture-absorption long-term heat-resistant aging-resistant polyamide composition and preparation method thereof

A polyamide composition and heat-resistant aging technology, which is applied in the field of low-moisture-absorbing long-term heat-resistant aging polyamide composition and its preparation, can solve the problems of decreased mechanical properties of the matrix, cost, and lower material water absorption, and achieve heat-resistant aging Excellent performance, high gas barrier performance, effects of protecting aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

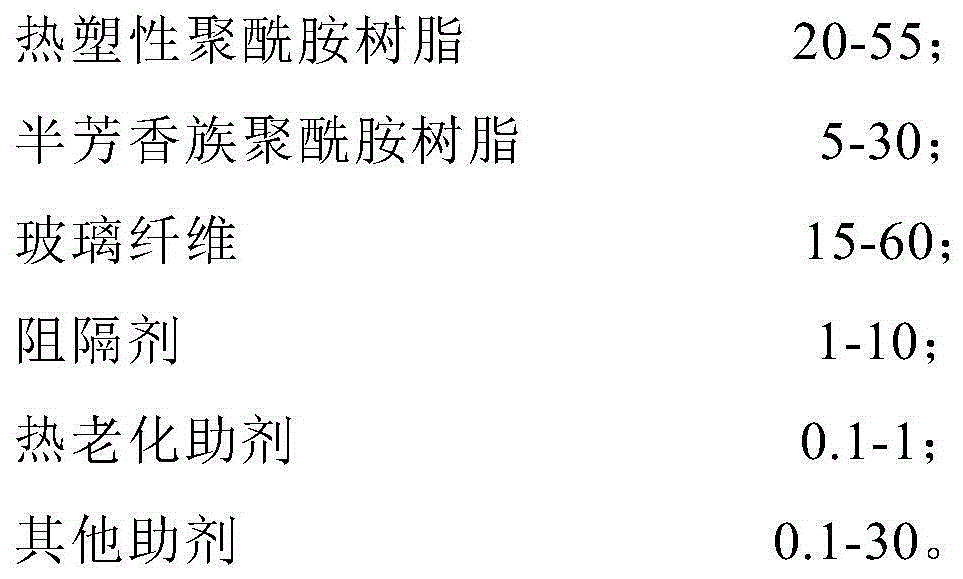

[0029] A low moisture absorption long-term heat-resistant aging polyamide composition and a preparation method thereof, comprising the following steps:

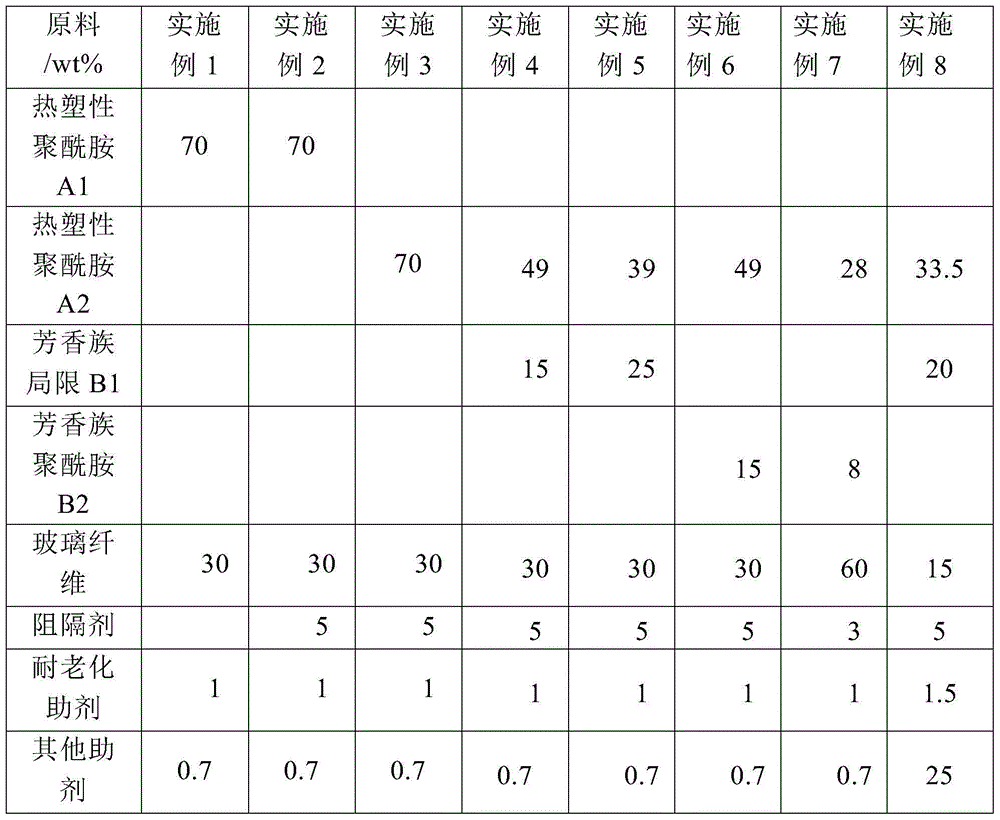

[0030] (1) Prepare materials according to the components and contents in Table 1.

[0031] Among them, the thermoplastic limited amine A1 is PA66, which is selected from PA66EPR2.7 of Shenma Group, and the content of terminal amino group is 46meq / Kg;

[0032] Thermoplastic limited amine A2 is PA6 / 66 copolymer, selected from Radici PA66 45C00H;

[0033] Aromatic polyamide B1 is PA6I, is selected from T40 of Bayer Company;

[0034] Aromatic polyamide B2 is PA6T / 6I copolymer, the ratio of PA6T:PA6I is 30:70;

[0035] The glass fiber is short glass fiber, which is 3360 of PPG company;

[0036] The barrier agent is ethylene-vinyl alcohol copolymer, with an ethylene content of 20-45%, which can be F171 from Kuraray;

[0037] The thermal aging aid is copper halide, preferably CuI, which can be 3320 of Langte Industrial Company; ...

Embodiment 8

[0039] "Other additives" in Example 8 are glass microspheres, treated with a silane coupling agent, which can be the brand name K1 of 3M Company.

[0040] (2) Put the above-mentioned raw materials except glass fiber into the high mixer and mix for 3-5 minutes, then discharge to obtain the mixture, and then control the processing temperature of the twin-screw extruder at 230-280°C, and the screw rotation speed at 180-600 rpm / min, the mixture is placed in a twin-screw extruder, the glass fiber enters from the glass fiber port, extruded and granulated, and the product is obtained

[0041] Table 1

[0042]

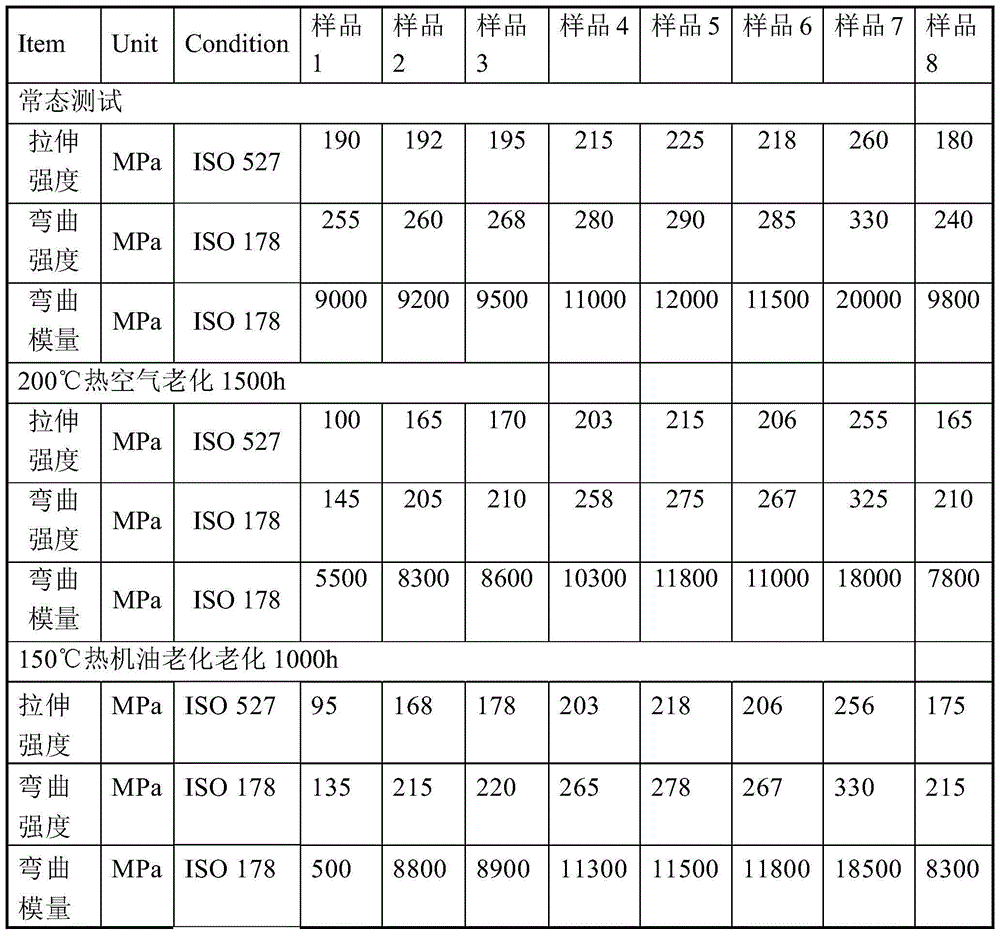

[0043] Samples 1-8 prepared according to Examples 1-8 were compared in performance tests using ISO standards. The aging test was carried out in a hot air aging box at 200°C, and the engine oil was selected from automotive transmission oil. The test performance comparisons are shown in Table 2.

[0044] Table 2

[0045]

Embodiment 9

[0047] A polyamide composition with low moisture absorption and long-term heat-resistant aging is prepared by using the following components and raw materials in weight percentage:

[0048] 20% of thermoplastic polyamide resin, 30% of semi-aromatic polyamide resin, 15% of glass fiber, 10% of barrier agent, 0.1% of thermal aging additive, and 24.9% of other additives. Among them, thermoplastic polyamide resin adopts a part of PA612 resin One or several kinds of copolymers, the amino-terminal content of the thermoplastic polyamide resin is at least 50meq / kg, and the semi-aromatic polyamide resin is obtained by polymerization of aliphatic dicarboxylic acid containing aromatic diamine and 8-20 carbon atoms A kind of polyamide or copolymer made, PAMXD6 is used in this embodiment, the glass fiber is the alkali-free glass fiber whose surface is treated with silane coupling agent, the diameter is 5μm, and the barrier agent is the copolymer of vinyl alcohol and ethylene, wherein ethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com