Waterproof roll and preparation method thereof

A waterproof membrane and membrane layer technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as surface loss, hairline cracks, microcracks, etc., to achieve photoaging inhibition, Improve weather resistance and aging resistance, good effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a waterproof membrane, which is a three-layer structure, the upper surface and the lower surface are both TPO membrane layers; the middle is a reinforcing layer of polyester mesh cloth, the warp fineness of the mesh cloth is 1000D, and the weft yarn The fineness is 1000D, and the total thickness of the product is 1.50mm.

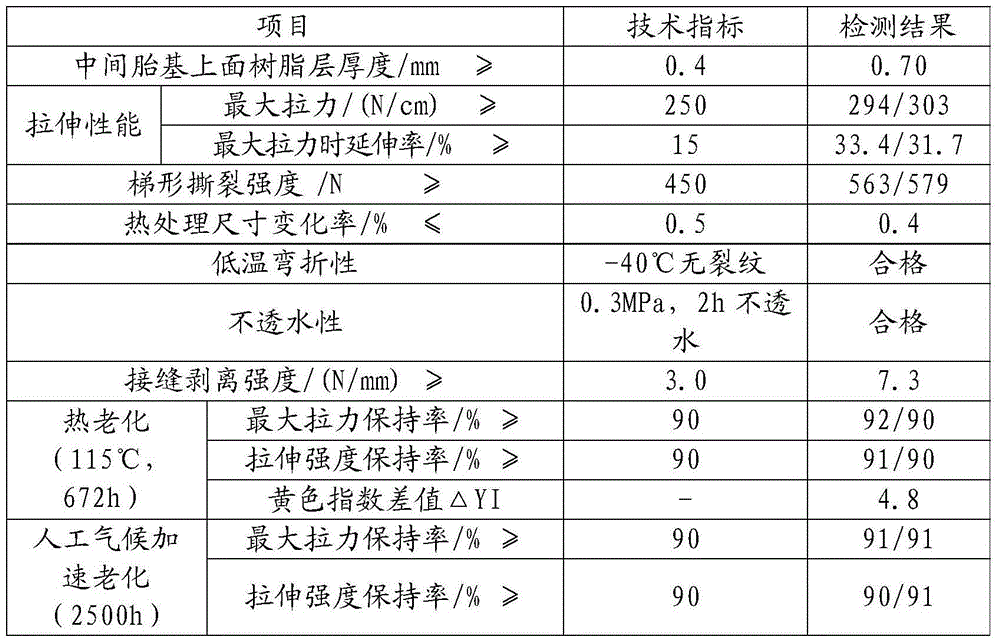

[0045] The components and parts by weight of the upper surface and the lower surface TPO membrane layer are shown in Table 1:

[0046] Components and parts by weight of the TPO membrane layer of Table 1, Example 1

[0047] raw material name

Upper surface TPO layer

Lower surface TPO layer

TPO

100

100

filler

20

25

Reinforcing agent

2

1

light shielding agent

3

1

paint

0

0.5

3.0

2.0

light stabilizer

1.5

1.0

1.5

1.0

[0048] The additives include antioxidants, ligh...

Embodiment 2

[0057] This embodiment provides a waterproof membrane, which is a three-layer structure, the upper surface and the lower surface are both TPO membrane layers; the middle is a reinforced polyester mesh cloth, the warp fineness of the mesh cloth is 1000D, and the weft yarn The fineness is 1000D, and the total thickness of the product is 1.50mm.

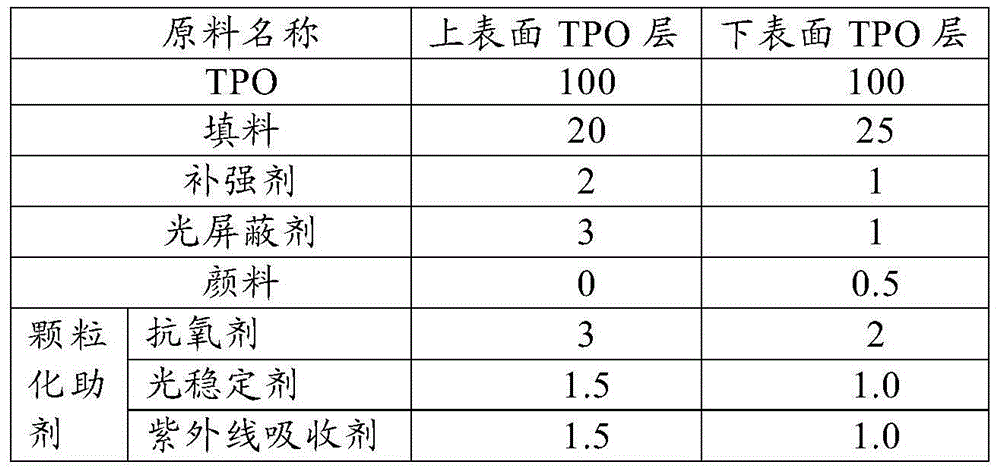

[0058] The components and parts by weight of the upper surface and the lower surface TPO membrane layer are shown in Table 3:

[0059] Components and parts by weight of the TPO membrane layer of table 3, embodiment 2

[0060]

[0061] The granulation auxiliary agent includes an antioxidant, a light stabilizer and an ultraviolet absorber, and the particle size of the granulation auxiliary agent is 0.5mm.

[0062] The main antioxidant is IRGANOX 245, the auxiliary antioxidant is IRGAFOS 168, wherein IRGANOX 245:IRGAFOS 168=1:1 (mass ratio), the light stabilizer is high molecular weight light stabilizer Chimassorb 2020 and low molecula...

Embodiment 3

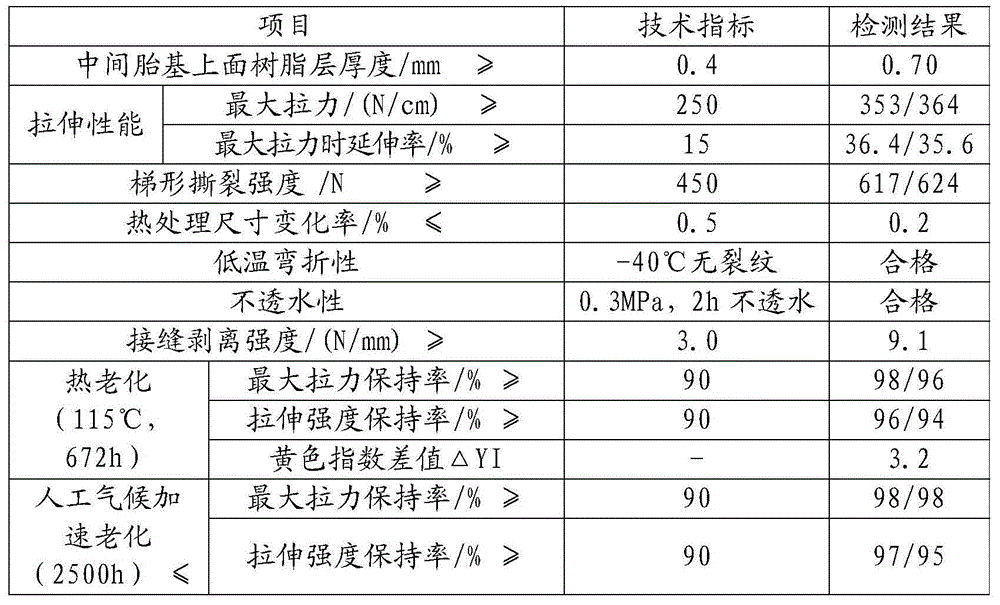

[0070] This embodiment provides a waterproof membrane, the preparation method of which is similar to that of embodiment 2, the difference between it and embodiment 2 is that the melt extrusion temperature of the screw extruder is 200°C; the operating temperature of the three-roll calender is 80°C. The components and parts by weight of each layer are shown in Table 5:

[0071] Components and parts by weight of the TPO membrane layer of Table 5 Example 3

[0072]

[0073] The granulation auxiliary agent includes an antioxidant, a light stabilizer and an ultraviolet absorber, and the particle size of the granulation auxiliary agent is 1.0 mm.

[0074] The main antioxidant is IRGANOX 245, the auxiliary antioxidant is IRGAFOS 168, wherein IRGANOX 245:IRGAFOS 168=1:2 (mass ratio), the light stabilizer is high molecular weight light stabilizer Chimassorb 2020 and low molecular weight light stabilizer It is matched with Tinuvin 770, wherein Chimassorb 2020:Tinuvin 770=1:1 (mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com