Heat aging-resisting and low-pressure change sulfur vulcanized EPDM (Ethylene-Propylene-Diene Monomer) rubber composition, preparation method, application and application product thereof

A technology of EPDM rubber and heat aging resistance, which is applied in the field of artificial rubber to achieve excellent physical and mechanical properties, improve heat aging resistance and low compression set performance, and reduce the effect of vulcanization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

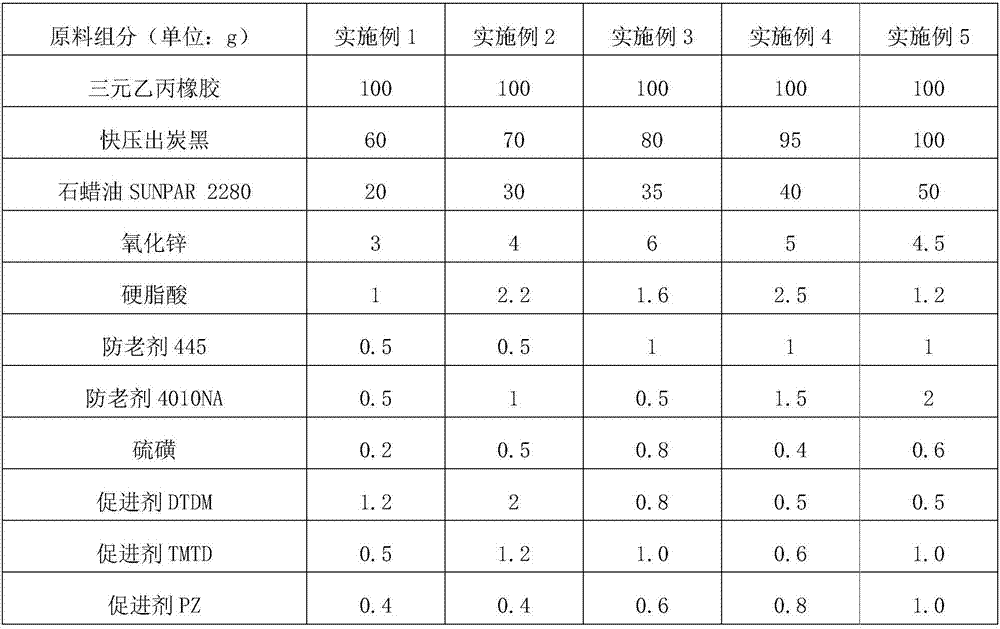

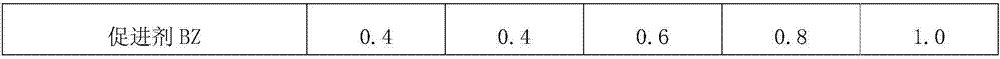

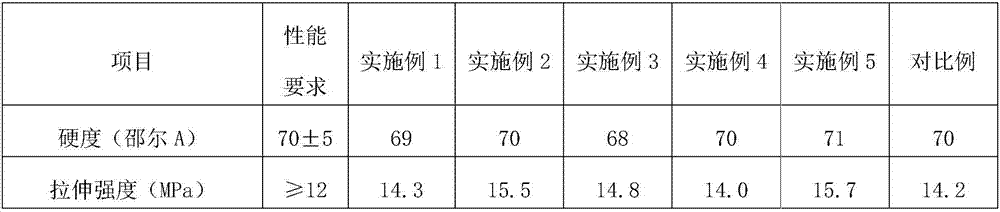

[0039] The technical solutions of the present invention will be further described below with reference to specific examples.

[0040] Table 1 embodiment 1-5 raw material components of sulfur-vulcanized EPDM rubber compositions and their proportions

[0041]

[0042]

[0043] Note:

[0044] (1) Anti-aging agent 445: 4.4'-bis(α.α'-dimethylbenzyl)diphenylamine;

[0045] (2) Anti-aging agent 4010NA: N-isopropyl-N'-phenyl-p-phenylenediamine;

[0046] (3) Accelerator DTDM: 4,4'-dithiodimorpholine;

[0047] (4) accelerator TMTD: tetramethylthiuram disulfide;

[0048] (5) accelerator PZ: zinc dimethyl dithiocarbamate;

[0049] (6) accelerator BZ: zinc di-n-butyl dithiocarbamate;

[0050] Weigh the raw material components according to the ratio shown in Table 1, and carry out the mixing and processing of the raw materials, including the following steps:

[0051] Put the formula amount of EPDM into the internal mixer for 1-2 minutes; then add the formula amount of zinc oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com