Liquid crystal polymer composition, preparation method and application thereof

A liquid crystal polymer and composition technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of insufficient strength and poor toughness, and achieve the effects of simple addition method, improved weld line strength, and good toughening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A preparation method of a liquid crystal polymer composition, comprising the following steps:

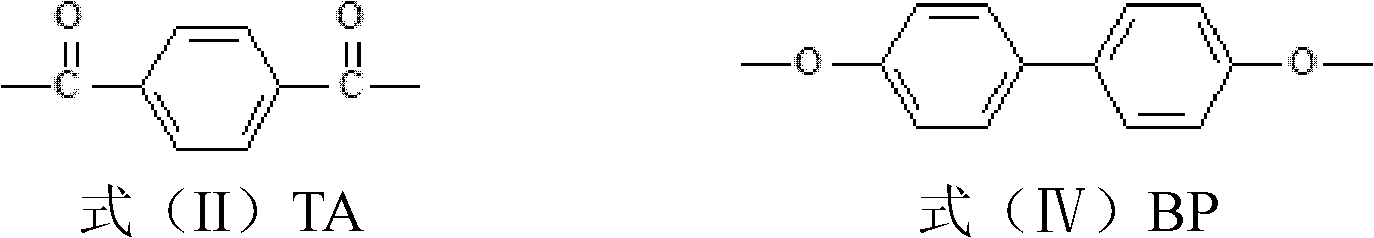

[0053] (1) Dry the liquid crystal polymer Ueno LCP A2500 (composed of PHBA / HNA / BP / TA, melting temperature 340°C) at 170°C for 4-6 hours, so that the water content is below 0.1% by mass;

[0054] (2) Take 38% of the liquid crystal polymer obtained in step (1) and 1% of silicone powder, 1% of tetrafluoroethylene and hexafluoropropylene copolymer (FEP) and blend them in a high-mixer to obtain a premixed system;

[0055] (3) The premixed system obtained in step (2) is added into the extruder from the main feeding port of the twin-screw extruder through the loss-in-weight metering scale; 30% of circular cross-section glass fibers and 30% of talcum The powder is fed into the extruder from the side feed port of the twin-screw extruder through a weight-loss weighing scale;

[0056] (4) extruding, drawing, cooling, and granulating to obtain a liquid crystal polymer composition;

[...

Embodiment 2

[0059] A preparation method of a liquid crystal polymer composition, comprising the following steps:

[0060] (1) Dry the liquid crystal polymer Ueno LCP A2500 (composed of PHBA / HNA / BP / TA, melting temperature 340°C) at 170°C for 4-6 hours, so that the water content is below 0.1% by mass;

[0061] (2) Take 37% of the liquid crystal polymer obtained in step (1) and 1% of silicone powder, 2% of tetrafluoroethylene and ethylene copolymer (ETFE) and blend them in a high-speed mixer to obtain a premixed system ;

[0062] (3) The premixed system obtained in step (2) is added into the extruder from the main feeding port of the twin-screw extruder through a weight-loss metering scale; The flakes are fed into the extruder from the side feed port of the twin-screw extruder through a weight-loss weighing scale;

[0063] (4) extruding, drawing, cooling, and granulating to obtain a liquid crystal polymer composition;

[0064] The percentages are percentages corresponding to the mass of the...

Embodiment 3

[0066] A preparation method of a liquid crystal polymer composition, comprising the following steps:

[0067] (1) Dry the liquid crystal polymer Ueno LCP A2500 (composed of PHBA / HNA / BP / TA, melting temperature 340°C) at 170°C for 4-6 hours, so that the water content is below 0.1% by mass;

[0068] (2) Take 52% of the liquid crystal polymer obtained in step (1) and 1% of silicone powder, 2% of tetrafluoroethylene and hexafluoropropylene copolymer (FEP) and blend them in a high-mixer to obtain a premixed system;

[0069] (3) The premixed system obtained by step (2) is added into the extruder from the main feeding port of the twin-screw extruder through the loss-in-weight metering scale; The loss-in-weight weighing scale is fed into the extruder from the side feeding port of the twin-screw extruder;

[0070] (4) extruding, drawing, cooling, and granulating to obtain a liquid crystal polymer composition;

[0071] The percentages are percentages corresponding to the mass of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com