Liquid crystal polymer material reinforced by glass fibers with non-circular cross sections and preparation method thereof

A non-circular cross-section, liquid crystal polymer technology, used in liquid crystal materials, chemical instruments and methods, etc., can solve problems such as unsatisfactory results, achieve good mechanical properties, narrow shrinkage differences, and high interface bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

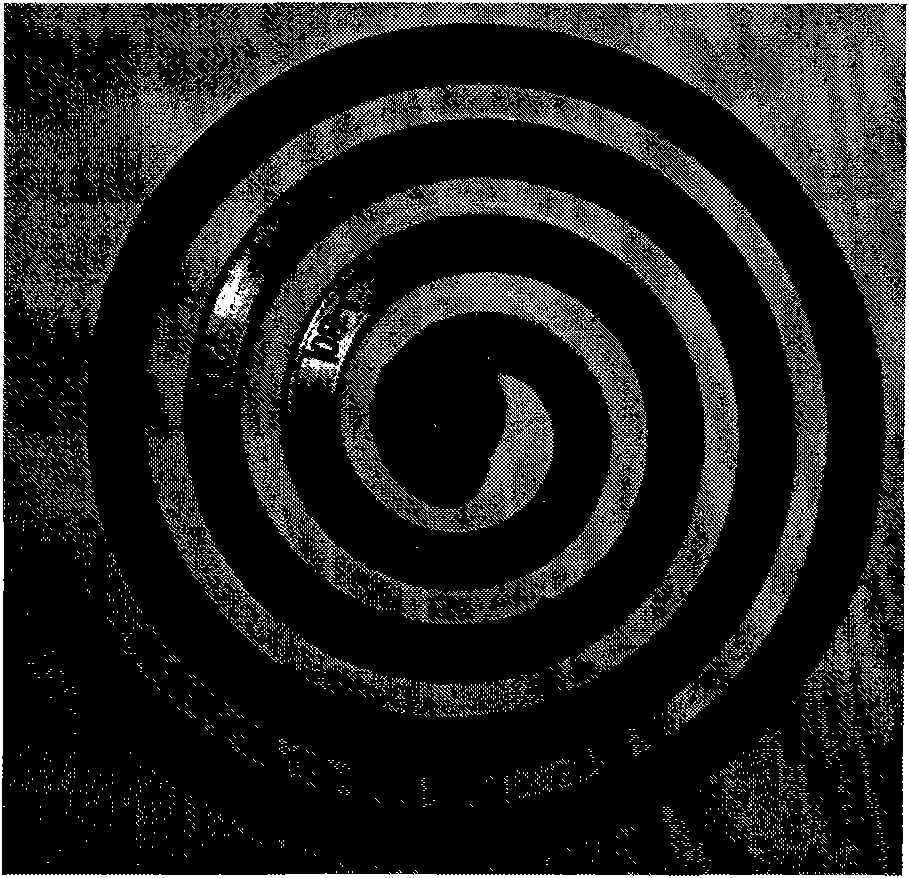

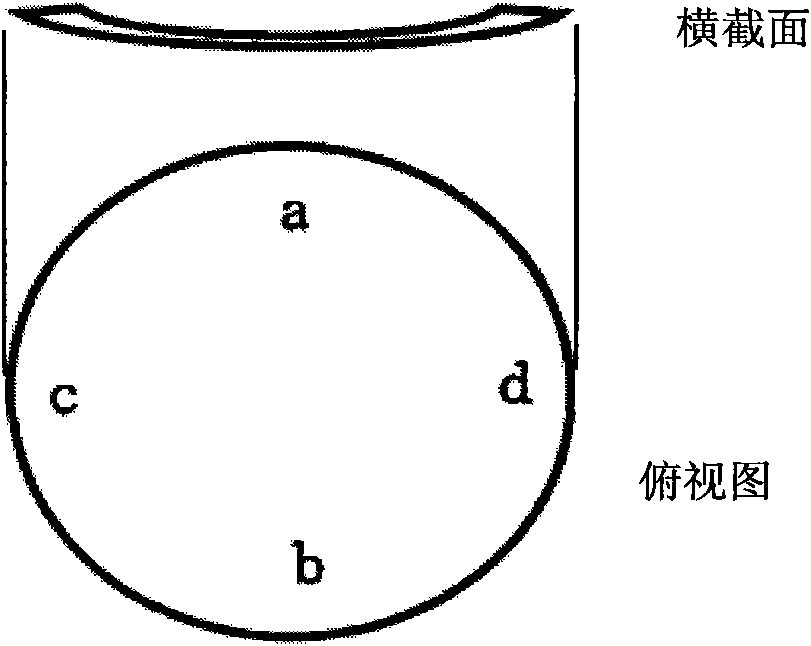

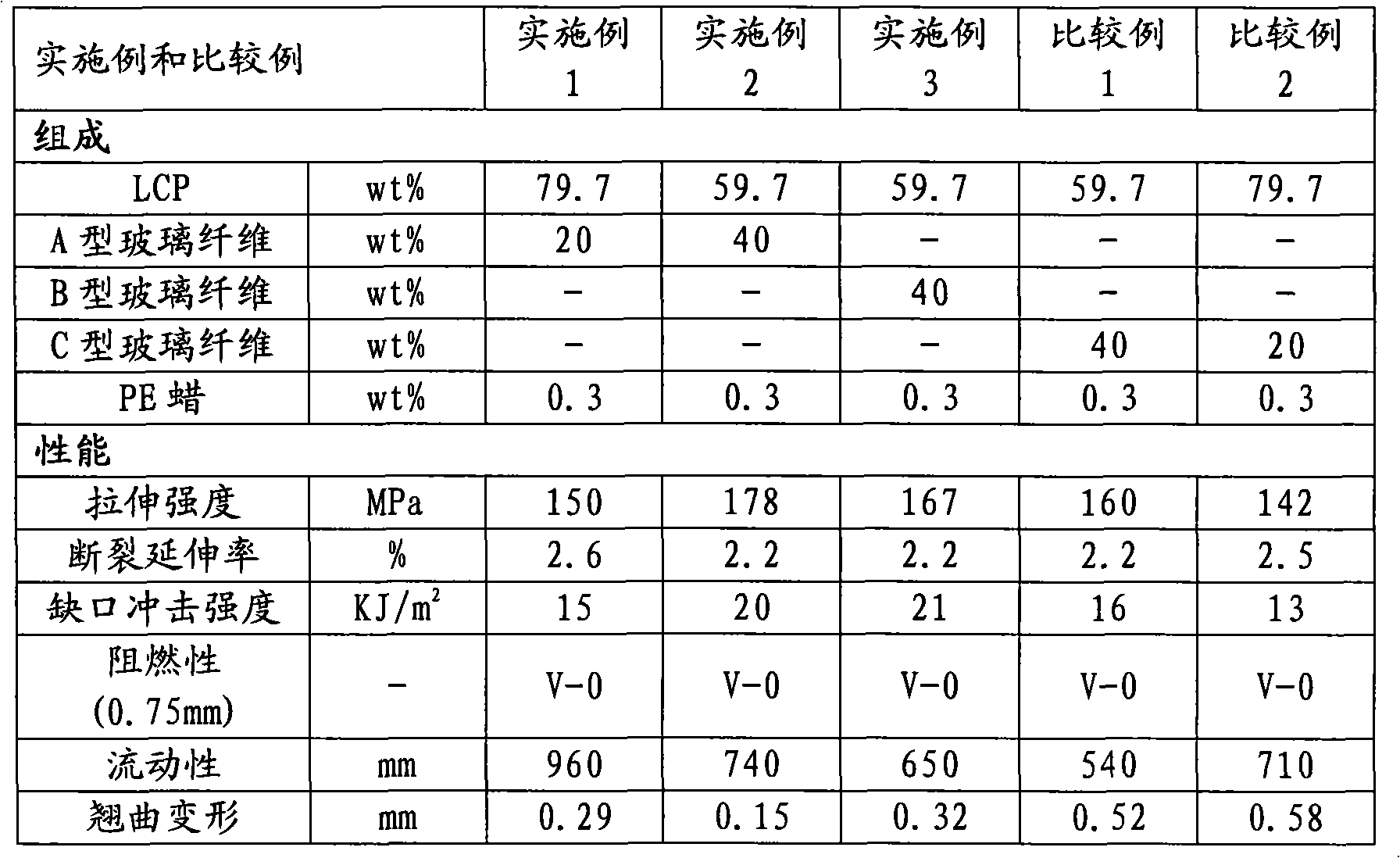

[0036] Type A glass fiber: rectangular cross-section glass fiber, 3mm long, 28μm wide, 7μm thick, flattening rate 4;

[0037] B-type glass fiber: cocoon-shaped cross-section glass fiber, 3mm long, 20μm wide, 10μm thick, and the flattening rate is 2;

[0038] C-type glass fiber: glass fiber with circular cross-section, 3mm long and 11μm in diameter;

[0039] It also includes LCP resin, polycarbonate, carbon fiber, 3000 mesh talc powder, PE wax lubricant and zeolite flame retardant synergist, etc.

[0040] The molding materials of the components in Table 1 were produced on a twin-screw extruder according to the manufacturing method described in the present invention. The produced molding materials were treated in a dehumidifying dryer at 160°C for 4 hours, and then molded in a conventional injection molding machine for the required samples for the following tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com