High weld mark strength enhanced polyamide material, preparation method thereof and application

A technology of polyamide and polyamide resin, which is applied in the field of polyamide materials with high weld line strength enhancement and its preparation, which can solve the problems of bad influence of weld line strength, low weld line strength, material application limitations, etc., and improve processing performance , Improve the strength of the weld line and broaden the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

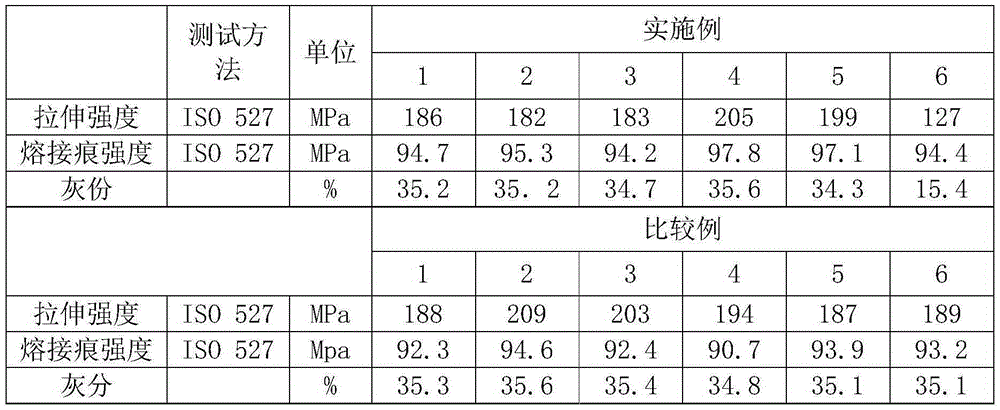

Examples

Embodiment 1

[0035] From the main feeding port, add 61.4% PA6 resin with a viscosity of 2.45 (measured in 95% concentrated sulfuric acid, the same below), 3% polyamide copolymer (PA3426, the same below), 0.4% high-efficiency nucleating agent (Clariant NAV101 , the same below) and 0.2% antioxidant (NylostabSEED and ultranox627A in a mass ratio of 1:1, the same below), and 35% surface-treated glass fiber (Chongqing International Composite Materials ECS301HP, below) was added to the side feeding port same). After melting, blending and extruding in a twin-screw extruder, it is cooled, air-dried, and pelletized into pellets. The pellets were injection molded into weld line strength test specimens for testing.

Embodiment 2

[0037] Add a mixture of 61.4% PA6 resin with a viscosity of 2.78, 3% polyamide copolymer, 0.4% high-efficiency nucleating agent and 0.2% antioxidant from the main feed port, and add 35% surface-treated glass fiber to the side feed port . After melting, blending and extruding in a twin-screw extruder, it is cooled, air-dried, and pelletized into pellets. The pellets were injection molded into weld line strength test specimens for testing.

Embodiment 3

[0039] A mixture of 58.4% PA6 resin with a viscosity of 2.78, 6% polyamide copolymer, 0.4% high-efficiency nucleating agent and 0.2% antioxidant is added from the main feed port, and 35% surface-treated glass fiber is added to the side feed port . After melting, blending and extruding in a twin-screw extruder, it is cooled, air-dried, and pelletized into pellets. The pellets were injection molded into weld line strength test specimens for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com