Modified nylon material with high weld line strength and preparation method thereof

A technology for modifying nylon and strength, which is applied in the field of modified nylon materials with high weld line strength and its preparation, to achieve the effect of improving the strength of weld lines and improving the dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

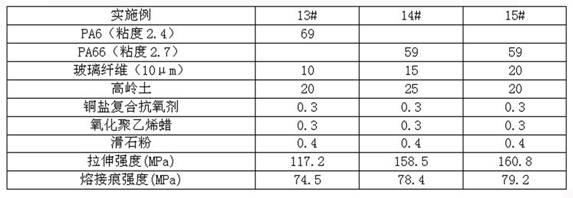

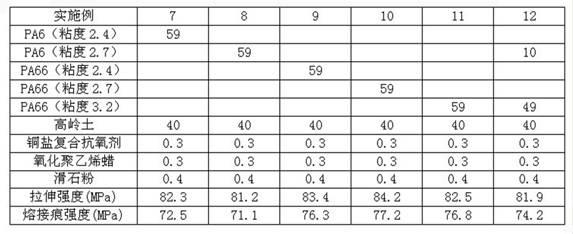

Examples

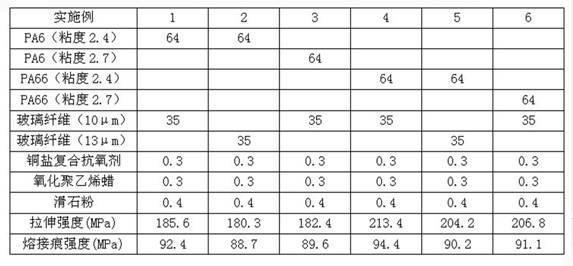

Embodiment 1

[0028] Add 64 parts by weight of nylon 6 (viscosity 2.4), 0.3 parts by weight of copper salt composite antioxidant, 0.3 parts by weight of oxidized polyethylene wax and 0.4 parts by weight of talcum powder into the high mixer, mix evenly at room temperature, and then pass through the twin-screw The main feed port of the extruder is passed into the extruder, and 35 parts by weight of glass fibers (10 μm) treated with an aminosilane coupling agent are passed into the extruder through the side feed port of the twin-screw extruder ; Use a twin-screw extruder to carry out extrusion granulation. The processing conditions for extrusion granulation are: the temperature of the first zone is 220°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 240°C, and the temperature of the fifth zone is 250°C. ℃, the temperature in the sixth zone is 250 ℃, the temperature in the seventh zone is 245 ℃, the temperature in ...

Embodiment 2

[0030] Add 64 parts by weight of nylon 6 (viscosity 2.4), 0.3 parts by weight of copper salt composite antioxidant, 0.3 parts by weight of oxidized polyethylene wax and 0.4 parts by weight of talcum powder into the high mixer, mix evenly at room temperature, and then pass through the twin-screw The main feed port of the extruder is passed into the extruder, and 35 parts by weight of glass fibers (13 μm) treated with an aminosilane coupling agent are passed into the extruder through the side feed port of the twin-screw extruder ; Use a twin-screw extruder to carry out extrusion granulation. The processing conditions for extrusion granulation are: the temperature of the first zone is 220°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 240°C, and the temperature of the fifth zone is 250°C. ℃, the temperature in the sixth zone is 250 ℃, the temperature in the seventh zone is 245 ℃, the temperature in ...

Embodiment 3

[0032]Add 64 parts by weight of nylon 6 (viscosity 2.7), 0.3 parts by weight of copper salt composite antioxidant, 0.3 parts by weight of oxidized polyethylene wax and 0.4 parts by weight of talcum powder into the high mixer, mix evenly at room temperature, and then pass through the twin-screw The main feed port of the extruder is passed into the extruder, and 35 parts by weight of glass fibers (10 μm) treated with an aminosilane coupling agent are passed into the extruder through the side feed port of the twin-screw extruder ; Use a twin-screw extruder to carry out extrusion granulation. The processing conditions for extrusion granulation are: the temperature of the first zone is 220°C, the temperature of the second zone is 230°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 240°C, and the temperature of the fifth zone is 250°C. ℃, the temperature in the sixth zone is 250 ℃, the temperature in the seventh zone is 245 ℃, the temperature in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com