A kind of pc/abs alloy with excellent welding line appearance and high strength and preparation method thereof

A welding line, high strength technology, applied in the field of PC/ABS alloy and its preparation, PC/ABS alloy, can solve the problems of poor effect, reduce the impact performance of materials, etc., achieve excellent weld line appearance, improve strength, and good appearance capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

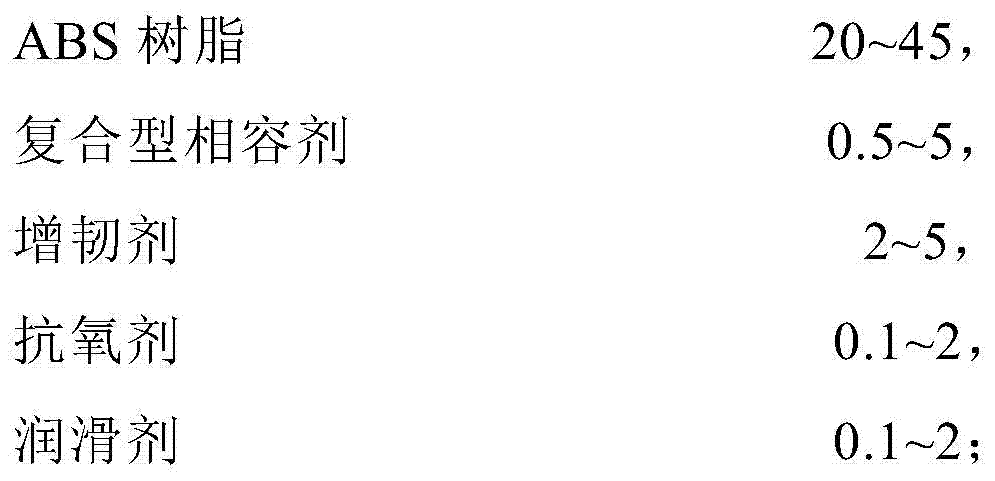

Method used

Image

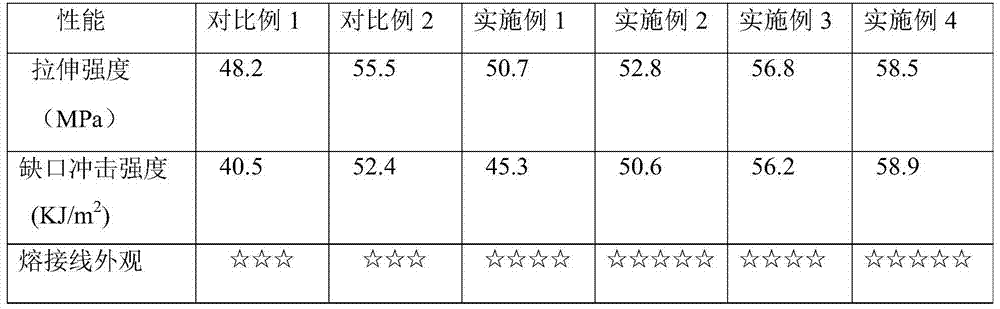

Examples

Embodiment 5

[0042] A method for preparing a PC / ABS alloy with excellent weld line appearance and high strength. The method comprises 80 parts by weight of 7025PJ type PC resin, 15 parts by weight of ABS3453 resin, 5 parts by weight of EM500 toughening agent, and 1 part by weight of SAG001 compatibilizer. , 0.5 parts by weight of EHP-g-SAN compatibilizer, 0.3 parts by weight of n-octadecyl propionate antioxidant, simethicone 0.2 parts by weight of lubricant is mixed uniformly in a high-speed mixer, and the uniformly mixed material is added to a twin-screw extruder for melt blending and extrusion. The extrusion temperature is controlled at 170-230°C, the screw speed is 200-500rpm, and the pressure is 2 ~3MPa, the product is obtained after underwater pelletizing and drying.

Embodiment 6

[0044] This example is basically the same as Example 3, except that Bayer's 2800 type PC resin is used to prepare a PC / ABS alloy with excellent weld line appearance and high strength.

Embodiment 7

[0046] This example is basically the same as Example 2, except that Bayer's 2800 PC resin and Chimei's PA-757 ABS resin were used to prepare a PC / ABS resin with excellent weld line appearance and high strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com